Evolution Of Total Quality Management

In today’s global competitive marketplace, the demands of customers are forever increasing as they require improved quality of products and services but are prepared to pay less for their requirement.

The chapter introduces the development of Total Quality Management (TQM) in construction industry, the definition, principles, standards and application of TQM are being discussed to gain more insight. Besides that, the interaction of TQM with the construction industry is being discussed to comprehend more regarding the application of these standards within the industry.

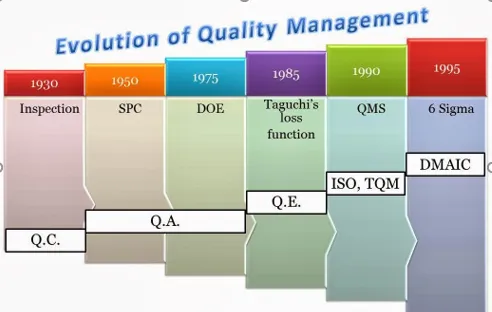

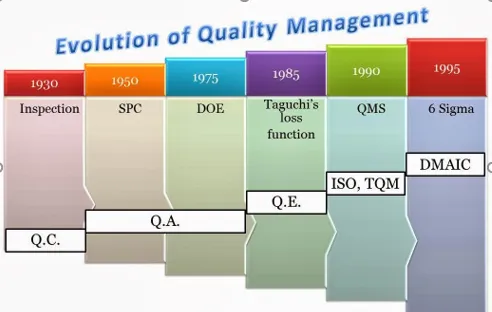

The chapter opens by examining the different interpretations which are placed on the word ‘quality’. The evolution of quality management is described through the stages of inspection, quality control, quality assurance and to TQM.

TQM is a revolutionary approach to effective management. In the construction industry, the application of TQM is not significant although it has been widely implemented in other industries and the success by implementing the TQM can be seen. TQM aimed at achieving customer satisfaction and efficiency, and improving the quality products.

The first part is to describe the application of TQM in the construction industry and the general perception of why TQM is not widely implemented in this industry. Key implementation issues of accomplishing TQM will also be addressed in the review.

In the eighteenth and nineteenth century, quality control did not exist as we can see today. However, some activities of quality control were carried out informally at workshop level (Garvin, 1988.3). Quality Control started to develop and spanned in the twentieth century (Feigenbaum, 1983:15). JC Penney was the first person who presented the importance of Total Quality Management (TQM) in 1913 when he proposed principles such as “customer satisfaction”, “quality”, “fairness”, “value”, “related training” and “rewards for performance” play an important role in an organisation (Jablonski, 1994:20-30). Moreover, in the early 1900s, “father of scientific management”, Fredrick W. Taylor, also suggested other quality principles (Garvin, 1988:5).

In the US, the development approach to quality control went through four significant stages: operator QC, inspection QC, statistical QC and total QC

The Building Research Establishment (BRE) in attempting to define quality related to buildings as:

“The totality of the attributes of a building which enable it to satisfy needs, including the way in which individual attributes are related, balanced and integrated in the whole building and its surroundings.”

The BRE report considered quality in the context of three main aspects:

External attributes – the effect of the project on its surrounding and vice versa

Performance attributes – aspects of the project which make it operationally efficient and provide reasonable conditions for users

Aesthetics and amenity – internal and external attributes of a standard higher than is needed just to meet mandatory and performance requirements.

Quality has nine different dimensions. These dimensions are somewhat independent, which means that an end product can be excellent in one dimension but poor in others (Besterfield, 1998). Below shows these nine dimensions and their terms:-

Performance

Primary products/service characteristic such as time, cost and workmanship aspect.

Features

Secondary characteristic, added consideration such as creativity in design and attractiveness.

Conformance

Meeting specification or industry standards, workmanship and client’s requirement in contract.

Reliability

Consistency of performance over time, average time for the unit to fail.

Durability

Useful life period with less maintenance or repair.

Service

Resolution of problems and complaints, ease of repair.

Response

Human to human interface such as efficiency during meeting, fast decision making, effective human resource management.

Aesthetics

Sensory characteristics in design such as exterior finishes.

Reputation

Past performance such as being ranked first in the tendering process.