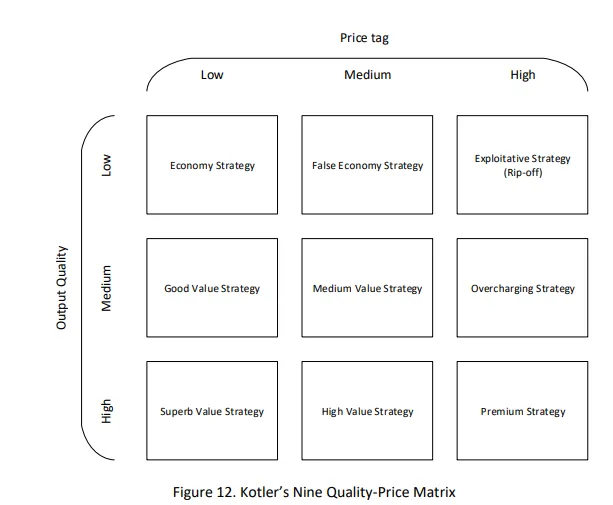

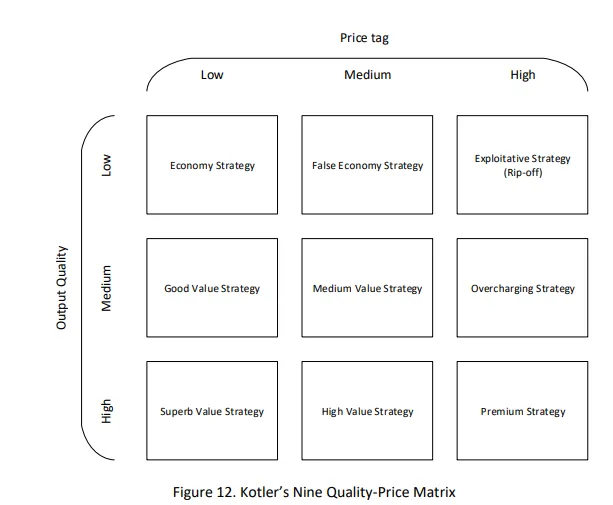

The Kotler nine quality-price matrix

When a company introduced a new product or service, a company need to consider its actual value to determine the selling price. By comparing the Quality of the firm’s product with its competitors, company could consider which market segment it wants to tackle and how should it product be priced. If your product is not priced appropriately, chances are you are going to lose sales and profits. There are cases when a product with lower quality can be more profitable than product which has higher standard simply because the lower quality one has better perceived quality, or the higher quality product was being sold at a lower price, making customers thinking that the product quality was lower than it actual quality. This mean that if the quality is not placed into the correct correlation to the price, the profits will be severely reduced. Therefore, firms need to know their brand positioning in correlation to competitors and their customer target group to select the correct strategy to use in every single situation. This is well-explained by Philip Kotler’s Quality-Price Matrix, where he identifies the 9 variations of pricing strategy based on these two metrics.

Firm need to balance and optimize these two metrics to achieve sustainable business model by deploying the correct pricing strategy. If not managed carefully, the quality and relationship can destroy a brand perceived quality, thus create a stigma which is hard to wash off.

Continuous Quality Improvement

In order for a firm to stay relevant to their counterparts, their products and services need to constantly be improved. The improvement can occur in multiple part of the supply chain, but the main goal of these implements is the satisfaction of the customers.

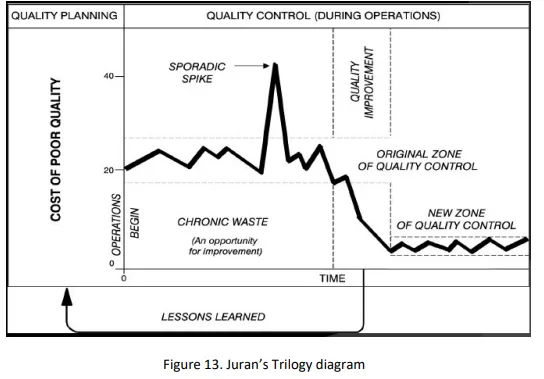

Juran in 1989 mentioned the possibility for improvement of quality by improving the customer satisfaction, product quality and delivery time. He reckoned if the communication between multiple departments can be improved, so can the Quality costs of the product and service. With that in mind, Juran Trilogy’s approach to macro process, or cross-functional system, are a combination of three processes: planning, control and improvement. This approach is based on the financial management processes which was being used for a long time, making the implementation of the approach easier conceptually.

The planning process is the activity of establishing the requirements for product or service in order to satisfy customers’ needs. By identify the target group and developing the feature based on the characteristics of that group and the operation capabilities, the planning process will maximize the chance to meet the customers’ requirements. Also, the planning process will set the control points for the process, which will be moved to the manufacturing team to begin the production.

The control process is based on the standards which are set during the planning period. During this process, products are examined and evaluated. If there are differences in performance (sporadic spike), usually unplanned maintenance or system failure, troubleshooting for problems are required, and based on the problems, suitable actions are deployed. Changes in this case are usually corrective actions or maintenance process. This mean that the time consumed for these kind of actions is useless and does not add value to the product or service, hence Juran deemed these kind of actions “chronic waste.” The end result is the resolve of the error and the operation level come back to the original setting.

The control process only help stabilize the quality, but to improve the Quality and increase its value, we need to ameliorate it. The improvement process is aiming to reduce the time taken for control the quality. In order to achieve such advancement in quality, Juran suggested the establishment of infrastructure is required to actively secure continuous improvement. This required top managers to identify the area which need to be improved, and afterward, back the project with time and personnel to diagnose the root of the problem. The end results is the improvement of the quality, bringing quality closer and closer to zero defects status. This later can be referred to Research and Development process.

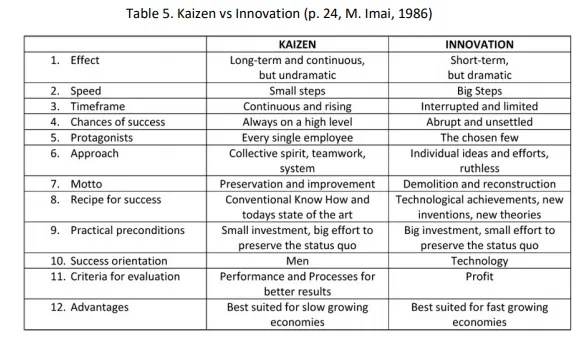

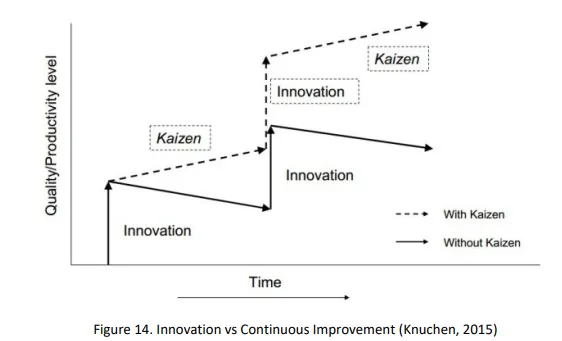

According to Maasaki Imai (今井 正明) (1986), there are two types of improvement: breakthrough or incremental. Breakthrough is a big leap innovation, which happen radically. This type of improvement usually happens in the West, while in the East, top managers usually want to implement new change slowly, in small steps. This process is called Kaizen. The figure below will explain more about the features of these two patterns of improvement

There are clear strengths and weaknesses in both types of improvement, for example, while Kaizen requires long-term investment into the company, which mean the results does not come out instantly, Innovation requires technological breakthrough in order to work, and does cost a significant amount of money when implemented. However, both of these approaches still pursuit the same goal: upgrade the performance of the system. Also, Imai realized that if combine these two patterns to form a symbiotic approach, that would be the best possible solution to any problems. Imai named this approach “continuous improvement”.

This diagram shows that, if human resource is well-trained, the Quality level will increase with time while the company waits for an innovation breakthrough. This combination of two process offsets both of the disadvantages of the two approaches but required top management responsibility to set up goals and directions in order to achieve that status.