Permanent Magnets and Electromagnets

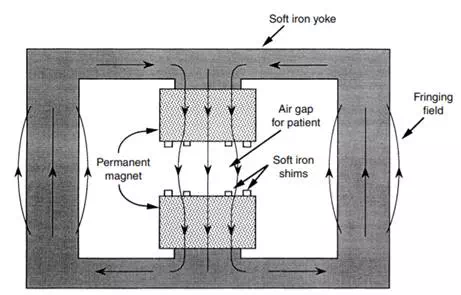

Both these magnet types use magnetized materials to produce the field that is applied to the patient. In a permanent magnet, the patient is placed in the gap between a pair of permanently magnetized pole faces. Electromagnets use a similar configuration, but the pole faces are made of soft magnetic materials, which become magnetized only when subjected to the influence of electric current coils that are wound around them. Electromagnets, but not permanent magnets, require the use of an external power supply. For both types of magnets, the magnetic circuit is completed by use of a soft iron yoke connecting the pole faces to one another (Figure 12.7). The gap between the pole faces must be large enough to contain the patient as well as the gradient and RF coils. The permanent magnet materials available for use in MRI scanners include high-carbon iron, alloys such as Alnico, ceramics such as barium ferrite, and rare earth alloys such as samarium cobalt.

Permanent magnet scanners have some advantages: they produce a relatively small fringing field and do not require power supplies. However, they tend to be very heavy (up to 100 T) can produce only relatively low fields — on the order of 0.3 T or less. They are also subject to temporal field drift caused by temperature changes. If the pole faces are made from an electrically conducting material, eddy currents induced in the pole faces by the pulsed gradient fields can limit performance as well. A recently introduced alloy of neodymium, boron, and iron (usually referred to as neodymium iron) has been used to make lighter-weight permanent magnet scanners.

FIGURE 12.7 Permanent magnet. The figure shows a schematic cross-section of a typical permanent magnet configuration. Electromagnets have a similar construction but are energized by current-carrying coils wound around the iron yoke. Soft magnetic shims are used to enhance the homogeneity of the field. (Reprinted with permission from Schenck and Leue, 1991.)