System engineering implementation

Definition and Purpose

Implementation

is the process that actually yields the lowest-level system elements in the

system hierarchy (system breakdown structure). System elements are made,

bought, or reused. Production involves the hardware fabrication processes of

forming, removing, joining, and finishing, the software realization processes

of coding and testing, or the operational procedures development processes for

operators' roles. If implementation involves a production process, a

manufacturing system which uses the established technical and management

processes may be required.

The

purpose of the implementation process is to design and create (or fabricate) a

system element conforming to that element’s design properties and/or

requirements. The element is constructed employing appropriate technologies and

industry practices. This process bridges the system

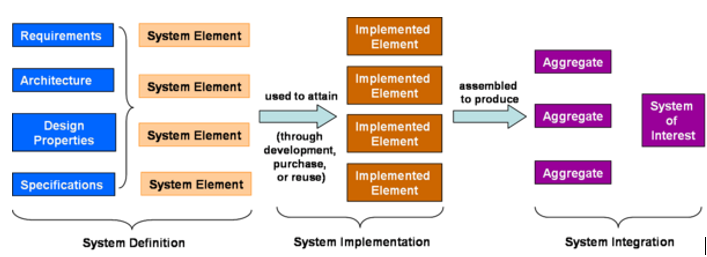

definition processes and the integration process. Figure 1 portrays how

the outputs of system definition relate to system implementation, which

produces the implemented (system) elements required to produce aggregates and

the SoI.

Figure 1. Simplification of How the Outputs of System

Definition Relate to System Implementation, which Produces the System Elements

Required to Produce Systems and Subsystems. (SEBoK

Original)

Process Approach

Purpose and Principle of the Approach

During

the implementation process, engineers apply the design properties and/or

requirements allocated to a system element to design and produce a detailed

description. They then fabricate, code, or build each individual element using

specified materials, processes, physical or logical arrangements, standards,

technologies, and/or information flows outlined in detailed descriptions

(drawings or other design documentation). A system element will be verified

against the detailed description of properties and validated against its

requirements.

If

subsequent verification and validation (V&V) actions or configuration

audits reveal discrepancies, recursive interactions occur, which includes

predecessor activities or processes, as required, to mitigate those

discrepancies and to modify, repair, or correct the system element in question.

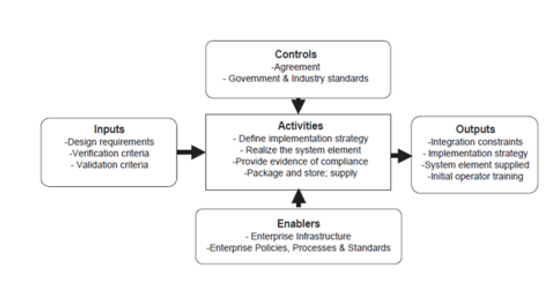

Figure 2 provides the context for the implementation process from the

perspective of the U.S. Defense Acquisition

University (DAU).

Figure 2. Context Diagram for the

Implementation Process (DAU 2010). Released by the Defense Acquisition University (DAU)/U.S. Department of Defense (DoD).

Such

figures provide a useful overview of the systems engineering (SE)

community’s perspectives on what is required for implementation and what the

general results of implementation may be. These are further supported by the

discussion of implementation inputs, outputs, and activities found in the

National Aeronautics and Space Association's (NASA's) Systems Engineering

Handbook (NASA 2007). It is important to understand that these views are

process -oriented. While this is a useful model, examining implementation only

in terms of process can be limiting.

Depending

on the technologies and systems chosen when a decision is made to produce a

system element, the implementation process outcomes may generate constraints to

be applied on the architecture of the higher-level system; those constraints

are normally identified as derived system requirements and added to the set of

system requirements applicable to this higher-level system. The architectural

design has tomust take those constraints into

account.

If

the decision is made to purchase or reuse an existing system element, it has tomust be identified as a constraint or system requirement

applicable to the architecture of the higher-level system. Conversely, the

implementation process may involve some adaptation or adjustments to the system

requirement in order to be integrated into a higher-level system or aggregate.

Implementation

also involves packaging, handling, and storage, depending on the concerned

technologies and where or when the system requirement needs to be integrated

into a higher-level aggregate. Developing the supporting documentation for a

system requirement, such as the manuals for operation, maintenance, and/or

installation, is also a part of the implementation process; these artifacts are utilized in the system deployment and use phase.

The system element requirements and the associated verification and validation

criteria are inputs to this process; these inputs come from

the architectural design process detailed outputs.

Execution

of the implementation process is governed by both industrial and government

standards and the terms of all applicable agreements. This may include

conditions for packaging and storage, as well as preparation for use

activities, such as operator training. In addition, packaging, handling,

storage, and transportation (PHS&T) considerations will constrain the

implementation activities. For more information, refer to the discussion of

PHS&T in the System Deployment and Use article. The developing or

integrating organization will likely have enterprise-level safety practices and

guidelines that must also be considered.

Activities of the Process

The

following major activities and tasks are performed during this process:

Define

the implementation strategy - Implementation process activities begin with

detailed design and include developing an implementation strategy that defines

fabrication and coding procedures, tools and equipment to be used,

implementation tolerances, and the means and criteria for auditing

configuration of resulting elements to the detailed design documentation. In

the case of repeated system element implementations (such as for mass

manufacturing or replacement elements), the implementation strategy is defined

and refined to achieve consistent and repeatable element production; it is retained

in the project decision database for future use. The implementation strategy

contains the arrangements for packing, storing, and supplying the implemented

element.

Realize

the system element - Realize or adapt and produce the concerned system

element using the implementation strategy items as defined above. Realization

or adaptation is conducted with regard to standards that govern applicable

safety, security, privacy, and environmental guidelines or legislation and the

practices of the relevant implementation technology. This requires the

fabrication of hardware elements, development of software elements, definition

of training capabilities, drafting of training documentation, and the training

of initial operators and maintainers.

Provide

evidence of compliance - Record evidence that the system element meets its

requirements and the associated verification and validation criteria as well as

the legislation policy. This requires the conduction of peer reviews and unit

testing, as well as inspection of operation and maintenance manuals. Acquire

measured properties that characterize the implemented element (weight,

capacities, effectiveness, level of performance, reliability, availability,

etc.).

Package,

store, and supply the implemented element - This should be defined in the

implementation strategy.

Artifacts and Ontology Elements

This

process may create several artifacts such as:

![]() an implemented system

an implemented system

![]() implementation tools

implementation tools

![]() implementation procedures

implementation procedures

![]() an implementation plan or strategy

an implementation plan or strategy

![]() verification reports

verification reports

![]() issue, anomaly, or trouble reports

issue, anomaly, or trouble reports

![]() change requests (about design)

change requests (about design)

This

process handles the ontology elements shown in Table 1 below.

|

Table 1. Main Ontology Elements as Handled within System Element

Implementation. (SEBoK Original) |

|

|

Element |

Definition Attributes (examples) |

|

Implemented Element |

An implemented element is a system element that has been implemented. In the case of hardware it is marked with a part/serial number. Identifier, name, description, type (hardware, software application, software piece, mechanical part, electric art, electronic component, operator role, procedure, protocol, manual, etc.) |

|

Measured Property |

A measured property is a characteristic of the implemented element established after its implementation. The measured properties characterize the implemented system element when it is completely realized, verified, and validated. If the implemented element complies with a design property, the measured property should equal the design property. Otherwise one has tomust identify the difference or non-conformance which treatment could conclude to modify the design property and possibly the related requirements, or to modify (correct, repair) the implemented element, or to identify a deviation. Identifier, name, description, type (effectiveness, availability, reliability, maintainability, weight, capacity, etc.), value, unit, etc. |

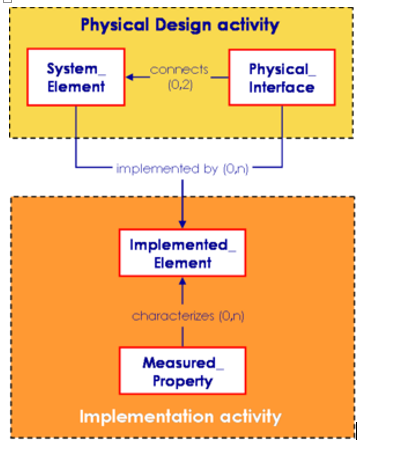

The main relationships between ontology elements are presented in Figure

3.

Figure 3. Implementation Elements

Relationships with Other Engineering Elements. (SEBoK

Original)

Methods, Techniques, and Tools

There

are many software tools available in the implementation and integration phases.

The most basic method would be the use of N-squared diagrams as discussed in

Jeff Grady’s book System Integration (Grady 1994).

Checking and Correctness of

Implementation

Proper

implementation checking and correctness should include testing to determine if

the implemented element (i.e., piece of software, hardware, or other product)

works in its intended use. Testing could include mockups

and breadboards, as well as modeling and simulation

of a prototype or completed pieces of a system. Once this is completed

successfully, the next process would be system integration.