Shock Absorbers

Shock absorbers are actually dampers, meaning that they reduce or make something less intense. The springs do the shock absorbing while the shocks dampen the spring oscillations. Without the shocks, our vehicles would continue to bounce for a long time after every bump, dip, and change in body movement. The most common type of shock is the direct doubleacting hydraulic shock absorber. This means that the shocks are used to directly act on motion; double acting means that they work in both compression and extension modes, and hydraulic means that a fluid is used to perform work. Compression is upward wheel travel, also called jounce. Extension is downward wheel motion and is also called rebound.

Shocks are typically mounted near the springs, with the lower end of the shock mounted on a lower control arm or axle, as shown in Figure 6-21. The top of the shock, which is connected to the shock piston, is mounted to the vehicle body. Inside the shock are two chambers, each partially filled with oil, as shown in Figure 6-22.

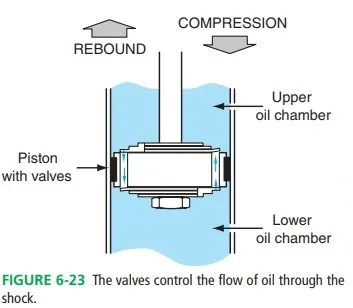

The shock piston moves up and down in the main chamber. This movement displaces the oil into a second chamber. A set of one-way valves control the flow of oil from the chambers. Moving the oil is difficult. This is where the shock’s resistance to movement comes from. Figure 6-23 shows the movement of oil through the valves and chambers. By allowing more oil to flow, a shock will dampen less and provide a smoother ride. By restricting oil flow, the shock will be more resistant to movement and provide a stiffer ride.

A shock may have an equal amount of resistance during both compression and extension, or it may have more resistance during extension. This is because the spring naturally resists compression, and the shock does not need to add much resistance to that of the spring. But since the spring will easily extend out, the shock’s greater resistance on extension can help better control spring action.