Suspensions, Functions, and Main Components

Suspension Systems

To many focusing on ride comfort, it may seem like the suspension system is merely a set of springs and shock absorbers which connect the wheels to the vehicle body. However, this is a very simplistic viewpoint of the suspension system. A vehicle suspension system provides a smooth ride over rough roads while ensuring that the wheels remain in contact with the ground and vehicle roll is minimized. The suspension system contains three major parts: a structure that supports the vehicle’s weight and determines suspension geometry, a spring that converts kinematic energy to potential energy or vice versa, and a shock absorber that is a mechanical device designed to dissipate kinetic energy.

An automotive suspension connects a vehicle’s wheels to its body while supporting the vehicle’s weight. It allows for the relative motion between wheel and vehicle body; theoretically, a suspension system should reduce a wheel’s degree of freedom (DOF) from 6 to 2 on the rear axle and to 3 on the front axle even though the suspension system must support propulsion, steering, brakes, and their associated forces. The relative motions of the wheels are its vertical movement, rotational movement about the lateral axes, and rotational movement about the vertical axes due to steer angle.

Main Components of Suspension Systems

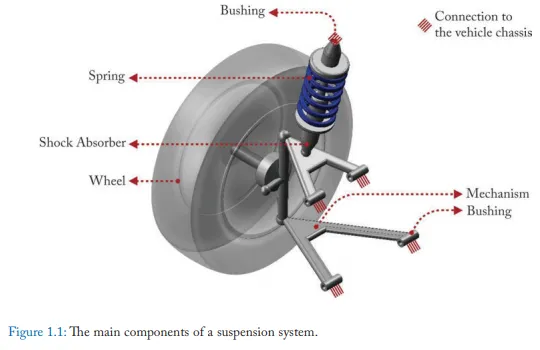

A vehicle suspension system is made of four main components-mechanism, spring, shock absorber, and bushings-as shown in Figure 1.1.

• Mechanism: The suspension mechanism might contain one or several arms that connect a wheel to the vehicle body. They transfer all forces and moments in different directions between the vehicle body and the ground. The mechanism determines some of the most important characteristics of a suspension system. It determines the suspension geometry and wheel angles and their relative motions. Variation in wheel angles during suspension travel causes a change in tire forces, which affect the vehicle’s road holding and handling. The main weight of a suspension system arises from its mechanism. Using heavy materials in its construction decreases the ride quality, whereas light materials, although improve ride quality, are more expensive.

• Spring: The spring is usually a winding wire or a number of strips of metal that have elastic properties. It supports the vehicle’s weight and makes a suspension tolerable for passengers. To best understand suspension behavior, the most important component requiring study is the spring. However, with its importance, a conflict arises: when using high stiffness springs, the vehicle exhibits good road holding and handling but with a noticeably decreased ride comfort. This creates a condition of limitation when choosing an appropriate spring stiffness. The spring weight and size may also make this accommodation difficult.

• Shock absorber: The shock absorber is a mechanical or hydraulic device to dampen impulses. A high damping shock absorber compromises the vehicle’s ride quality in order to immediately dampen impulses to improve handling and road holding.

• Bushings: The bushings prevent the direct contact of two metal objects in order to isolate noise and minimize vibration. Soft materials such as rubber is used in bushings for isolation. In fact, they are a type of vibration isolator used to connect various moving components to the vehicle body or suspension frame. Many types of bushing exist, and they are classified by the number of DOF between the two connected parts that they support. Revolute joints are the most common type of bushings. They are annular cylindrical and support a rotational relative motion, whereas ball joints allow rotational relative motion in all directions. Bushings are some of the most expensive parts in a suspension system.