TURBOCHARGER

A turbocharger or turbo is a forced induction

device used to allow more power to be produced for an engine of a given size. A

turbocharged engine can be more powerful and efficient than a naturally

aspirated engine because the turbine forces more intake air, proportionately

more fuel, into the combustion chamber than if atmospheric pressure alone is

used. Turbo are commonly used on truck, car, train, and construction equipment

engines. Turbo are popularly used with Otto cycle and Diesel cycle internal combustion

engines.

There are two ways of increasing the power of

an engine. One of them would be to make the fuel-air mixture richer by adding

more fuel. This will increase the power but at the cost of fuel efficiency and

increase in pollution levels… prohibitive! The other would be to somehow

increase the volume of air entering into the cylinder and increasing the fuel

intake proportionately, increasing power and fuel efficiency without hurting

the environment or efficiency. This is exactly what Turbochargers do,

increasing the volumetric efficiency of an engine.

In a naturally aspirated engine, the downward

stroke of the piston creates an area of low pressure in order to draw more air

into the cylinder through the intake valves. Now because of the

pressure in the cylinder cannot go below 0 (zero) psi (vacuum) and relatively

constant atmospheric pressure (about 15 psi) there will be a limit to the

pressure difference across the intake valves and hence the amount of air

entering the combustion chamber or the cylinder. The ability to fill the

cylinder with air is its volumetric efficiency. Now if we can increase the

pressure difference across the intake valves by some way we can make more air

enter into the cylinder and hence increasing the volumetric efficiency of the

engine.

It increases the pressure at the point where

air is entering the cylinder, thereby increasing the pressure difference across

the intake valves and thus more air enters into the combustion chamber. The

additional air makes it possible to add more fuel, increasing the power and

torque output of the engine, particularly at higher engine speeds.

Turbochargers were originally known as Turbo

superchargers when all forced induction devices were classified as

superchargers; nowadays the term "supercharger" is usually applied to

only mechanically-driven forced induction devices. The key difference between a

turbocharger and a conventional supercharger is that the latter is mechanically

driven from the engine, often from a belt connected to the crankshaft, whereas

a turbocharger is driven by the engine's exhaust gas turbine. Compared to a

mechanically-driven supercharger, turbochargers tend to be more efficient but

less responsive.

HISTORICAL PERSPECTIVE

The turbocharger was invented by Swiss

engineer Alfred Büchi. His patent for a turbocharger was applied for use in

1905. Diesel ships and locomotives with turbochargers began appearing in the

1920s.

AVIATION:

During the First World War French

engineer Auguste Rateau fitted

turbochargers to Renault engines powering various French fighters with some

success. In1918, General Electric engineer Sanford Moss attached a turbo to a

V12 Liberty aircraft engine. The engine was tested at Pikes Peak in Colorado at

4,300 m to demonstrate that it could eliminate the power losses usually

experienced in internal combustion engines as a result of reduced air pressure

and density at high altitude.

Turbochargers were first used in production

aircraft engines in the 1920s, although they were less common than

engine-driven centrifugal superchargers. The primary purpose behind most

aircraft-based applications was to increase the altitude at which the airplane

could fly, by compensating for the lower atmospheric pressure present at high

altitude.

PRODUCTION AUTOMOBILES:

The first turbocharged diesel truck was

produced by Schweizer Maschinenfabrik Saurer(Swiss Machine Works Saurer) in 1938 .The first production turbocharged automobile

engines came from General Motors in 1962. At the Paris auto show in1974, during

the height of the oil crisis, Porsche introduced the 911 Turbo – the world’s

first production sports car with an exhaust turbocharger and pressure

regulator. This was made possible by the introduction of a waste gate to direct

excess exhaust gasses away from the exhaust turbine. The world's first

production turbo diesel automobiles were the Garrett-turbocharged Mercedes

300SD and the Peugeot 604, both introduced in 1978. Today, most automotive

diesels are turbocharged.

1962 Oldsmobile Cutlass Jet fire

1962 Chevrolet Corvair Monza Spyder

1973 BMW 2002 Turbo

1974 Porsche 911 Turbo

1978 Saab 99

1978 Peugeot 604 turbo diesel

1978 Mercedes-Benz 300SD turbo diesel (United

States/Canada)

1979 Alfa Romeo Alfetta GTV 2000 Turbodelta

1980 Mitsubishi Lancer GT Turbo

1980 Pontiac Firebird

1980 Renault 5 Turbo

1981 Volvo 240-series Turbo

OPERATING PRINCIPLE

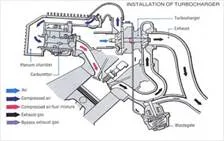

A turbocharger is a small radial fan pump

driven by the energy of the exhaust gases of an engine. A turbocharger consists

of a turbine and a compressor on a shared shaft. The turbine converts exhaust

heat to rotational force, which is in turn used to drive the compressor. The compressor

draws in ambient air and pumps it in to the intake manifold at increased

pressure resulting in a greater mass of air entering the cylinders on each

intake stroke.

The objective of a turbocharger is the same as

a supercharger; to improve the engine's volumetric efficiency by solving one of

its cardinal limitations. A naturally aspirated automobile engine uses only the

downward stroke of a piston to create an area of low pressure in order to draw

air into the cylinder through the intake valves. Because the pressure in the

atmosphere is no more than 1 atm (approximately 14.7 psi), there ultimately will be

a limit to the pressure difference across the intake valves and thus the amount

of airflow entering the combustion chamber.

Because the turbocharger increases the

pressure at the point where air is entering the cylinder, a greater mass of air

(oxygen) will be forced in as the inlet manifold pressure increases. The

additional air flow makes it possible to maintain the combustion chamber

pressure and fuel/air load even at high engine revolution speeds, increasing

the power and torque output of the engine. Because the pressure in the cylinder

must not go too high to avoid detonation and physical damage, the intake

pressure must be controlled by venting excess gas. The control function is

performed by a waste gate, which routes some of the exhaust flow away from the

turbine. This regulates air pressure in the intake manifold.

COMPONENTS OF A TURBOCHARGER

The turbocharger has four main components. The

turbine (almost always a radial turbine) and impeller/compressor wheels are

each contained within their own folded conical housing on opposite sides of the

third component, the centre housing/hub rotating assembly. The housings fitted

around the compressor impeller and turbine collect and direct the gas flow

through the wheels as they spin. The size and shape can dictate some

performance characteristics of the overall turbocharger. The turbine and

impeller wheel sizes dictate the amount of air or exhaust that can be flowed

through the system, and the relative efficiency at which they operate.

Generally, the larger the turbine wheel and compressor wheel, the larger the

flow capacity. The centre hub rotating assembly houses the shaft which connects

the compressor impeller and turbine. It also must contain a bearing system to

suspend the shaft, allowing it to rotate at very high speed with minimal

friction. Waste gates for the exhaust flow.

TURBINE WHEEL:

The Turbine Wheel is housed in the turbine

casing and is connected to a shaft that in turn rotates the compressor wheel.

COMPRESSOR WHEEL (IMPELLER)

Compressor impellers are produced using a

variant of the aluminium investment casting process. A rubber former is made to

replicate the impeller around which a casting mould is created. The rubber

former can then be extracted from the mould into which the metal is poured.

Accurate blade sections and profiles are important in achieving compressor

performance. Back face profile machining optimizes impeller stress conditions.

Boring to tight tolerance and burnishing assist balancing and fatigue

resistance. The impeller is located on the shaft assembly using a threaded nut.

WASTE GATES:

On the exhaust side, a Waste gate provides us

a means to control the boost pressure of the engine. Some commercial diesel

applications do not use a Waste gate at all. This type of system is called a

free-floating turbocharger. However, the vast majority of gasoline performance

applications require Waste gates. Waste gates provide a means to bypass exhaust

flow from the turbine wheel. Bypassing this energy (e.g. exhaust flow) reduces

the power driving the turbine wheel to match the power required for a given

boost level.

ADVANTAGES

1. More

specific power over naturally aspirated engine. This means a turbocharged

engine can achieve more power from same engine volume.

2. Better

thermal efficiency over both naturally aspirated and supercharged engine when

under full load (i.e. on boost). This is because the excess exhaust heat and

pressure, which would normally be wasted, contributes some of the work required

to compress the air.

3. Weight/Packaging.

Smaller and lighter than alternative forced induction systems and may be more

easily fitted in an engine bay.

4. Fuel

Economy. Although adding a turbocharger itself does not save fuel, it will

allow a vehicle to use a smaller engine while achieving power levels of a much

larger engine, while attaining near normal fuel economy while off

boost/cruising. This is because without boost, less fuel is used to create a

proper air/fuel ratio.

DISADVANTAGES

1. Lack

of responsiveness if an incorrectly sized turbocharger is used. If a

turbocharger that is too large is used it reduces throttle response as it

builds up boost slowly otherwise known as "lag". However, doing this

may result in more peak power.

2. Boost

threshold- A turbocharger starts producing boost only above a certain rpm due

to a lack of exhaust gas volume to overcome inertia of rest of the turbo

propeller. This results in a rapid and nonlinear rise in torque, and will

reduce the usable power band of the engine. The sudden surge of power could

overwhelm the tires and result in loss of grip, which could lead to under

steer/over steer, depending on the drive train and suspension setup of the

vehicle. Lag can be disadvantageous in racing, if throttle is applied in a

turn, power may unexpectedly increase when the turbo spools up, which can cause

excessive wheel spin.

3. Cost-

Turbocharger parts are costly to add to naturally aspirated engines. Heavily

modifying OEM turbocharger systems also require extensive upgrades that in most

cases requires most (if not all) of the original components to be replaced.

4. Complexity-

Further to cost, turbochargers require numerous additional systems if they are

not to damage an engine. Even an engine under only light boost requires a

system for properly routing (and sometimes cooling) the lubricating oil,

turbo-specific exhaust manifold, application specific downpipe, boosts

regulation. In addition inter -cooled turbo engines require additional

plumbing, while highly tuned turbocharged engines will require extensive

upgrades to their lubrication, cooling, and breathing systems; while

reinforcing internal engine and transmission parts.

TURBO LAG AND BOOST

The time required to bring the turbo up to a

speed where it can function effectively is called turbo lag. This is noticed as

a hesitation in throttle response when coming off idle. This is symptomatic of

the time taken for the exhaust system driving the turbine to come to high

pressure and for the turbine rotor to overcome its rotational inertia and reach

the speed necessary to supply boost pressure. The directly-driven compressor in

a supercharger does not suffer from this problem. Conversely on light loads or

at low RPM a turbocharger supplies less boost and the engine acts like a

naturally aspirated engine. Turbochargers start producing boost only above a

certain exhaust mass flow rate (depending on the size of the turbo). Without an

appropriate exhaust gas flow, they logically cannot force air into the engine.

The point at full throttle in which the mass flow in the exhaust is strong

enough to force air into the engine is known as the boost threshold rpm.

Engineers have, in some cases, been able to reduce the boost threshold rpm to

idle speed to allow for instant response. Both Lag and Threshold

characteristics can be acquired through the use of a compressor map and a

mathematical equation.

APPLICATIONS

Gasoline-powered cars

Today, turbocharging is commonly used by many

manufacturers of both diesel and gasoline-powered cars. Turbo charging can be

used to increase power output for a given capacity or to increase fuel

efficiency by allowing a smaller displacement engine to be used. Low pressure

turbocharging is the optimum when driving in the city, whereas high pressure

turbocharging is more for racing and driving on highways/motorways/freeways.

Diesel-powered cars

Today, many automotive diesels are

turbocharged, since the use of turbocharging improved efficiency, driveability

and performance of diesel engines, greatly increasing their popularity.

Motorcycles

The first example of a turbocharged bike is

the 1978 Kawasaki Z1R TC. Several Japanese companies produced turbocharged high

performance motorcycles in the early 1980s. Since then, few turbocharged

motorcycles have been produced.

Trucks

The first turbocharged diesel truck was

produced by Schweizer Maschinenfabrik Saurer(Swiss Machine Works Saurer) in 1938.

Aircraft

A natural use of the turbocharger is with

aircraft engines. As an aircraft climbs to higher altitudes the pressure of the

surrounding air quickly falls off. At 5,486 m (18,000 ft), the air is at half the

pressure of sea level and the airframe experiences only half the aerodynamic

drag. However, since the charge in the cylinders is being pushed in by this air

pressure, it means that the engine will normally produce only half-power at

full throttle at this altitude. Pilots would like to take advantage of the low drag

at high altitudes in order to go faster, but a naturally aspirated engine will

not produce enough power at the same altitude to do so.

Here the main aim is to effectively utilize

the non-renewable energy such as petrol and diesel. Complete combustion of the

fuels can be achieved. Power output can be increased. Wind energy can be used

for air compression. We conclude that the power as well as the efficiency is

increasing 10 to 15 % and pollution can also decrease. From the observation we

can conclude that when the full throttle valve is open at that time the engine

speed is 4000 rpm and by this the turbocharger generate 1.60 bar pressurized

air. Generally the naturally aspirated engine takes atmospheric pressurized air

to the carburettor for air fuel mixture but we can add the high density air for

the combustion so as the result the power and the complete combustion take

place so efficiency is increasing.