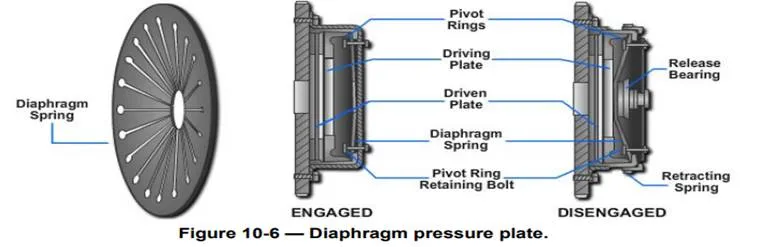

Diaphragm Pressure Plate

The diaphragm pressure plate (Figure 10-6) uses a single diaphragm spring instead of coil springs. The diaphragm spring is a large, round disc of spring steel. The spring is bent or dished and has pie-shaped segments running from the outer edge to the center. The diaphragm spring is mounted in the pressure plate with the outer edge touching the back of the pressure plate face. The outer rim of the diaphragm is secured to the pressure plate and is pivoted on rings approximately 1 inch from the outer edge. Application of pressure at the inner section of the diaphragm will cause the outer rim to move away from the flywheel and draw the pressure plate away from the clutch disc, disengaging the clutch.

Clutch Disc

Wet Type A “wet” clutch is immersed in a cooling lubricating fluid, which also keeps the surfaces clean and gives smoother performance and longer life. Wet clutches, however, tend to lose some energy to the liquid. Since the surfaces of a wet clutch can be slippery, stacking multiple clutch discs can compensate for the lower coefficient of friction and so eliminate slippage under power when fully engaged. Wet clutches are designed to provide a long, service-free life. They often last the entire life of the machine they are installed on. If you must provide service to a wet clutch, refer to the manufacturer’s service manual for specific details

Dry Type

The clutch disc, also called friction lining, is a “dry” clutch and consists of a splined hub and a round metal plate covered with friction material (lining). The splines in the center of the clutch disc mesh with the splines on the input shaft of the manual transmission. This makes the input shaft and disc turn together. However, the disc is free to slide back and forth on the shaft. Clutch disc torsion springs, also termed damping springs, absorb some of the vibration and shock produced by clutch engagement. They are small coil springs located between the clutch disc splined hub and the friction disc assembly. When the clutch is engaged, the pressure plate jams the stationary disc against the spinning flywheel. The torsion springs compress and soften as the disc first begins to turn with the flywheel. Clutch disc facing springs, also called the cushioning springs, are flat metal springs located under the friction lining of the disc. These springs have a slight wave or curve, allowing the lining to flex inward slightly during initial engagement. This also allows for smooth engagement. The clutch disc friction material, also called disc lining or facing, is made of heatresistant asbestos, cotton fibers, and copper wires woven or molded together. Grooves are cut into the friction material to aid cooling and release of the clutch disc. Rivets are used to bond the friction material to both sides of the metal body of the disc.