Two-Stroke Cycle Diesel Engine:

The cycle of the four-stroke of the piston (the suction, compression, power and exhaust strokes) is completed only in two strokes in the case of a two-stroke engine. The air is drawn into the crankcase due to the suction created by the upward stroke of the piston. On the down stroke of the piston it is compressed in the crankcase, The compression pressure is usually very low, being just sufficient to enable the air to flow into the cylinder through the transfer port when the piston reaches near the bottom of its down stroke.

The air thus flows into the cylinder, where the piston compresses it as it ascends, till the piston is nearly at the top of its stroke. The compression pressure is increased sufficiently high to raise the temperature of the air above the self-ignition point of the fuel used. The fuel is injected into the cylinder head just before the completion of the compression stroke and only for a short period. The burnt gases expand during the next downward stroke of the piston. These gases escape into the exhaust pipe to the atmosphere through the piston uncovering the exhaust port.

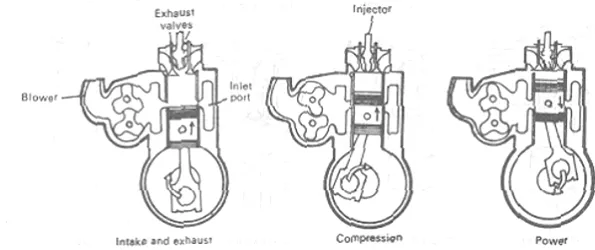

Modern Two-Stroke Cycle Diesel Engine

The crankcase method of air compression is unsatisfactory, as the exhaust gases do not escape the cylinder during port opening. Also there is a loss of air through the exhaust ports during the cylinder charging process. To overcome these disadvantages blowers are used to precompress the air. This pre-compressed air enters the cylinder through the port. An exhaust valve is also provided which opens mechanically just before the opening of the inlet ports