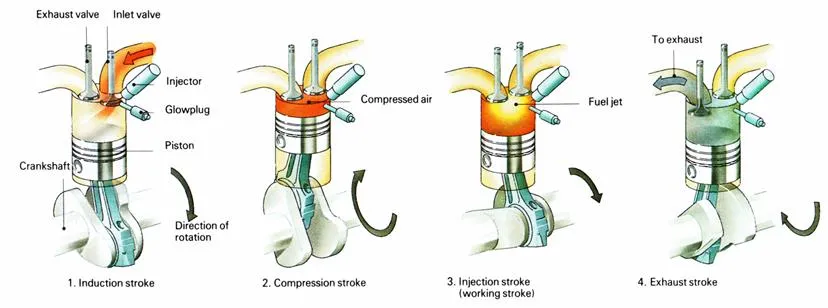

Principles of Operation Of IC Engines: Four-Stroke Cycle Diesel Engine

In four-stroke cycle engines there are four strokes completing two revolutions of the crankshaft. These are respectively, the suction, compression, power and exhaust strokes. In Fig. 3, the piston is shown descending on its suction stroke. Only pure air is drawn into the cylinder during this stroke through the inlet valve, whereas, the exhaust valve is closed. These valves can be operated by the cam, push rod and rocker arm. The next stroke is the compression stroke in which the piston moves up with both the valves remaining closed. The air, which has been drawn into the cylinder during the suction stroke, is progressively compressed as the piston ascends. The compression ratio usually varies from 14:1 to 22:1. The pressure at the end of the compression stroke ranges from 30 to 45 kg/cm2 . As the air is progressively compressed in the cylinder, its temperature increases, until when near the end of the compression stroke, it becomes sufficiently high (650-80O oC) to instantly ignite any fuel that is injected into the cylinder. When the piston is near the top of its compression stroke, a liquid hydrocarbon fuel, such as diesel oil, is sprayed into the combustion chamber under high pressure (140-160 kg/cm2 ), higher than that existing in the cylinder itself. This fuel then ignites, being burnt with the oxygen of the highly compressed air.

During the fuel injection period, the piston reaches the end of its compression stroke and commences to return on its third consecutive stroke, viz., power stroke. During this stroke the hot products of combustion consisting chiefly of carbon dioxide, together with the nitrogen left from the compressed air expand, thus forcing the piston downward. This is only the working stroke of the cylinder.

During the power stroke the pressure falls from its maximum combustion value (47-55 kg/cm2 ), which is usually higher than the greater value of the compression pressure (45 kg/cm2 ), to about 3.5-5 kg/cm2 near the end of the stroke. The exhaust valve then opens, usually a little earlier than when the piston reaches its lowest point of travel. The exhaust gases are swept out on the following upward stroke of the piston. The exhaust valve remains open throughout the whole stroke and closes at the top of the stroke.

The reciprocating motion of the piston is converted into the rotary motion of the crankshaft by means of a connecting rod and crankshaft. The crankshaft rotates in the main bearings, which are set in the crankcase. The flywheel is fitted on the crankshaft in order to smoothen out the uneven torque that is generated in the reciprocating engine.

Principle of four-stroke engine