Disc Brakes

Although drum brakes have the advantages of self-energization and ease of parking brake incorporation, they suffer from several disadvantages. Their heat dissipation is problematic, and drum brakes are prone to brake fade as the drum becomes hot due to extended or frequent heavy braking. Also, drum brakes are very sensitive to moisture or contamination inside the drum. Any water in the drum rapidly vaporizes under braking, causing the coefficient of friction of the shoe to become nearly zero.

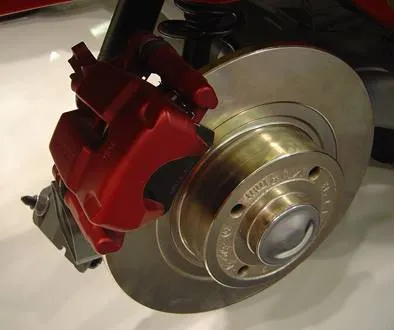

On the other hand, disc brakes do not suffer these handicaps. The rotors can be vented to aid heat dissipation, and any water or contamination of the rotor is quickly removed by the scraping action of the pads. Figure 9.14 shows a typical disc brake system.

Disc Brake Components

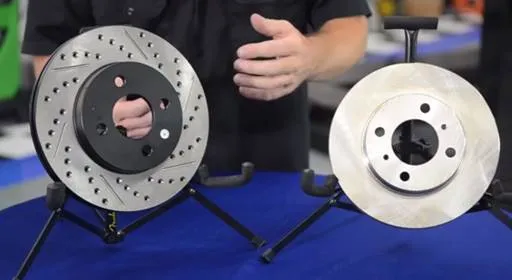

Brake Disc

The brake disc, also called the rotor, is connected to the wheel hub. The rotor provides the friction surface for the pads, thus generating the braking torque. Rotors usually are vented to aid in the dissipation of heat. Some rotors also are cross drilled to save weight. High-performance brakes now are using carbon fiber as a rotor material. Carbon fiber provides good, fade-free performance when the material has been heated. Many Formula 1 teams use carbon fiber brakes, and the driver must ride the brake during the warm-up laps to bring them up to operating temperature. The performance of these brakes under such demanding conditions is attested to by the fact that the rotors often glow red hot after the brakes have been applied during a race. The wheels are connected to the rotor by the lugs.

Brake Pads

The brake pads, consist of a stamped steel backing plate to which the friction material is attached. The material, also called the lining, may be bonded to the plate with adhesive, or it may be riveted. Most disc brakes also contain a wear indicator. This indicator is a small tab of spring steel, the edge of which is set to a predetermined height below the surface of the new pad. When the pad wears to the point where it should be replaced, the spring steel begins to rub on the rotor when the brakes are applied. This produces an irritating squeal that is intended to motivate the driver to have the brake pads replaced. Should the driver ignore the warning, the brakes will continue to function to the point where no lining material remains. The author has had the experience of a fairly new disc brake pad disintegrating during a stop. During the subsequent trip home, the rivet heads remaining on the backing plate provided more than adequate stopping power, although at great damage to the rotor.

Caliper

The brake caliper houses the pistons, and these pistons apply the activation force to the brake pads. The caliper may house as few as one or as many as six pistons, depending on the specific vehicle in question. Calipers fall into two categories: (1) fixed, or (2) floating.