Thermoelectric Cooler : A new horizon in Mechanical and Electronics Engineering

The Thermoelectric (TEC) innovation was first found by a French physicist named Jean Peltier that is why it is also known as a pettier cooler. The main principle behind Peltier effect is that when current is allowed to pass through the circuit of various conductors, heat is either retained or discharged at the conductor’s intersections or junctions depend upon their extremity like current polarity. The measure of heat conduction generated or absorbed is corresponding to inter pass with different conductors.

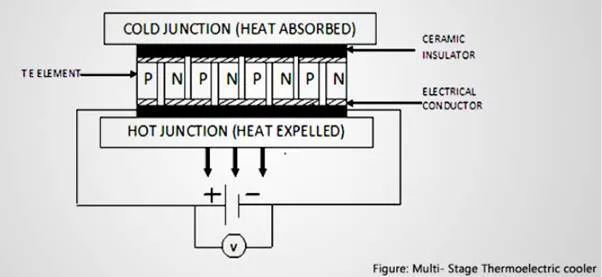

The Peltier cooler unit is integrated with the set of thermocouple consisting p- and n-type semiconductor elements, or pellets, sandwiched between two ceramic plates. Pairs are combined into a module. It is connected electrically in series so that equi-distribution of current will take place and thermally in parallel so that heat conduction is properly maintained. A heat sink is a device that is attached to the hot side of the thermoelectric module. It is used to facilitate the transfer of heat from the hot side of the module to the environment. A cold sink is attached to the cold side of the module which facilitates heat transfer.

In general, when a DC voltage is applied across the device, one face cools while the other face heats up. The module itself is made up of p-type and n-type semiconductors connected electrically in series and thermally in parallel. The p-type element has a deficiency of electrons compared to its n-type counterpart, which has a surplus of electrons. In order to complete the lattice of material, the electrons flow from the n-type to the p-type material and holes from p-type to n-type maintained in a material through an electrical connector, dropping to a lower energy state and releasing energy heat to the heat sink (hot side).

Thermoelectric cooler can be of two types:-

1.

Single stage Thermoelectric cooler

2. Multi-stage Thermoelectric cooler

Single stage thermoelectric coolers work at the permissible range at the temperature difference of 74-76 degrees Kelvin. In order to create a great difference in the temperature range, many research is going on multi-stage thermoelectric coolers are used. For example, the maximum temperate difference of one of the serial thermoelectric coolers is 140 degrees, Kelvin.

Advantage:

1.

No release of harmful substances which can affect the environment.

2. The thermoelectric cooler doesn’t require any fluid, gases for cooling.

3. It doesn’t emit any noise.

4. Lesser size and weight of thermoelectric cooler are reduced.

5. A thermoelectric cooler is reliable.

6. Its cooling and heating capacity can be adjustable.

Application:

1.

Military/Aerospace: Inertial guidance systems, night vision equipment,

electronic equipment, cooled personal garments, portable refrigerators.

2. Consumer products: Recreational vehicle refrigerators, mobile home

refrigerators, portable picnic coolers, wine and beer keg coolers, residential

water coolers/ purifiers.

3. Laboratory and scientific equipment: Infrared detectors, integrated circuit

coolers, laboratory cold plates, cold chambers, ice point reference baths, dew

point hygrometers.

4. Industrial Equipment: Computer microprocessors, microprocessors in numerical

control and robotics, medical instruments, hypothermia blankets, pharmaceutical

refrigerators- portable and stationary, blood analysers, tissue preparation and

storage, restaurants equipment, cream and butter dispensers.

5. Miscellaneous: Hotel room refrigerators, automobile mini – refrigerators,

automobile seal cooler, aircraft drinking water coolers.