Challenges and Opportunities in lithium-ion battery technologies for electric vehicles

The automotive industry’s quest to limit its impact on the environment and transform automotive mobility into a sustainable mode of transportation continues at high intensity, despite the current economic crisis. The major issue which is still haunting the electric vehicles is the technology and cost of lithium-ion batteries. Normally, the value chain of electric vehicle batteries consists of raw material for production, cell production, module production, assembly of modules into the battery pack, integration of the battery pack into the vehicle, use during the life of the vehicle, and reuse and recycling.

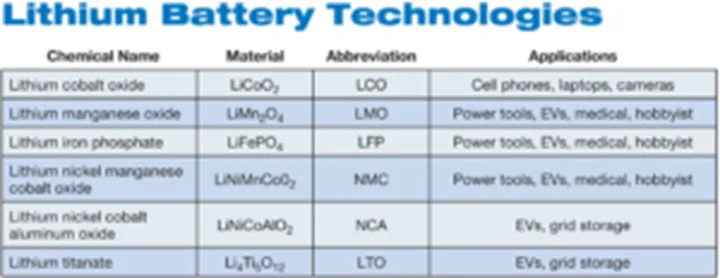

Lithium-ion batteries comprise a family of battery chemistries that employ various combinations of anode and cathode materials. The most prominent technologies for automotive applications are lithium-nickel-cobalt-aluminium(NCA), Lithium-nickel-manganese-cobalt(NMC), Lithium-manganese spinel(LMO), Lithium titanate(LTO) and Lithium-ion phosphate (LFP). The technology that is currently most prevalent in consumer application is lithium-cobalt oxide(LCO), which is generally considered unsuitable for automotive applications because of its inherent safety risks.

The

key performance parameters for electric vehicle batteries are discussed in

succeeding paras.

Safety: It is the most important criterion. The main concern is thermal runaway. In this the chemical reactions triggered in the cell exacerbate heat release, and thus resulting in a fire.

Life Span: Two ways of measuring battery life span are cycle stability and overall age. Cycle stability is the number of times a battery can be fully charged and discharged before being degraded to 80 percent of its original capacity at full charge. Overall age is the number of years a battery can be expected to remain useful.

Specific Energy and Specific Power: The specific energy of batteries is their capacity for storing energy per kilogram of weight. Specific power is the amount of power that batteries can deliver per kilogram of mass. There is a need to optimize the trade-off between specific energy and specific power.

Charging Time: It almost takes ten hours to charge a 15-Kwh battery by plugging it into a standard 120-volt outlet. 240-volt outlet with increased power (40 amps) can take two hours. Charging at a commercial three-phase charging station can take as little as 20 mins. However, these charging systems do come at an additional cost and weight, as they require enhanced cooling systems in the vehicle.

The challenge and tremendous opportunity still remains with cell manufacturers. As of now chemical companies and component producers tend to see the electric vehicle business as representing only a small percentage of their overall revenues. They will ultimately supply active materials, separators and other key parts for cell manufacturing. The continued growth of the market for electric vehicles will finally depend on new battery technologies, and the will of governments as well as on driving patterns and definitely on price of gasoline.