vehicle chassis and frame design

Automotive industry is one of the biggest and most innovative in total industry area. Almost all manufactured cars and vehicle are made by mass production but in the very beginning the cars were produced by the same technologies of hand craftsmanship that had been used for centuries for the construction of horse-drawn carriages. Due to the issue of large number of components and assembly rely on joining items the procedure has been changed. It has been started by Henry Ford who developed the techniques of mass production based on preliminary production of rifles during American Civil War. The line production was based on special tracks, so the car’s chassis were moved through next assembly stations with overhead store components. Thus the motor industry from small workshops producing hand-build vehicle changed into huge corporation with mass production techniques with components supply chain. Second main factor of changing the production processes and techniques was construction development. From the first construction based on horse-drawn carriages with wooden chassis and framework to the modern constructions of steel, lightweight steel (or even ULSAB – Ultra Lightweight Steel Auto Body) or fiber constructions. In addition to the direct engineering issues the vehicle designer needs to consider the political issues such as pollution and recycling. Thus the research on materials of engine and vehicle body in terms of environmental and safety are constant conducted. The novel materials cause changes in construction due to the different physical and mechanical properties [1-7].

First commercial vehicles (lorries and buses) were based on steam-powered carriages. The typical example was the steam-engined road vehicle based on railway technology. By the time of First and Second World War the commercial road vehicle industry has developed. One of the most specific group of commercial vehicles are special heavy vehicles operating often in off-road conditions in different environment and on irregular ground surface. The issues of absorption of vibration, vehicle dynamics and stability in terrain become big factors for developing project and new constructions. These type of vehicles have large scope of loads, from general cargo to concrete. It can be designed, developed, produced and installed truck bodies and trailers for any kind of use according to special and individual requirements [8-10].

The very first stage of the vehicle production has to be design. Design can be considered as an activity to find the best (optimal) solution to an engineering problem within certain constraints. The whole process involving solution from conception to evaluation, including safety, comfort, aesthetics, ergonomics, manufacture and cost. Designing is an integrated, multi-stage operation, which must be flexible to allow modifications for specific problems and all requirements arise during whole process. One of the management technique used for design is IPPD (Integrated Product and Process Development). IPPD facilitates meeting cost and performance objectives from product concept through production, including field support. There are 10 key tends of IPPD:

- customer focus,

- concurrent development of products and processes,

- early and continuous life cycle planning,

- maximize flexibility for optimization and use of contractor unique approaches,

- encourage robust design and improved process capability,

- event-driven scheduling,

- multidisciplinary teamwork,

- empowerment,

- seamless management tools,

- proactive identification and management risk .

The requirements for modern cars and heavy vehicles cause many tasks in vehicle design. Beside the fundamental tasks as proper identification of engine, transmission system, steering, suspension, brakes in terms of safety, utility and comfort the material properties and structure geometry become more and more important. Also the noise, vibration and harshness become important requirements for the customer. It has to be emphasized the role of endurance and durability in design and manufacture of reliable vehicle.

The requirements for utility vehicles have increased as well. The range and scope of potential use and application possibilities become very wide. Thus these vehicles start to be considered for the customer not only in terms of utility but more often in terms of comfort and safety as it is in passenger cars. These are the reasons for innovation solutions in modern vehicle. One of those is intermediate frame. The requirements for the intermediate frame are focused on loads (goods) or vehicle use and stability of body (superstructure). As far as vehicle application or load requirements determine shape and volume of the construction, the stability will be realized as stiffness and spring/damping properties of the connections. Torsionally stiff bodies may not affect the torsional flexibility of the chassis frame. They must be connected to the chassis so that they are torsionally flexible in accordance with the specifications of the body/equipment mounting directives. Fixed bearings and pivot bearings are used for this purpose. Due to types of special bodies the mounting of implements and bodies become very important [13].

The process of chassis design consists of:

- load case,

- chassis type,

- structural analysis.

Very important issue of vehicle design is selection of material according to require experimental and analytical data and maintenance properties (i.e. corrosion resistance). Nowadays a wide range of alloys in available with different properties, heat treatments and manufacturing opportunities. Thus these materials have now replaced steel and copper alloys in many vehicle components. New materials as aluminum alloys, polymers and composite materials are more often used even as vehicle bodywork (body panel). Thus the first stage will determine which group of metals or other materials can be used according to experimental and analytical data. Depending on the application the design engineer has to consider the material and mechanical properties due to the forces expected during the operation of the vehicle. A sufficiently strong force will produce a definite amount of deformation. Thus the designers and engineers have to understand and compare many parameters of the materials. For example:

- Strength is the ability of material to withstand a force without permanent deformation.

- Compressive strength is the ability to withstand a pushing force.

- Torsional strength is the ability to withstand twisting force.

Other important properties are: tensile strength, elasticity, plasticity, hardness, toughness, dimensional stability and durability.

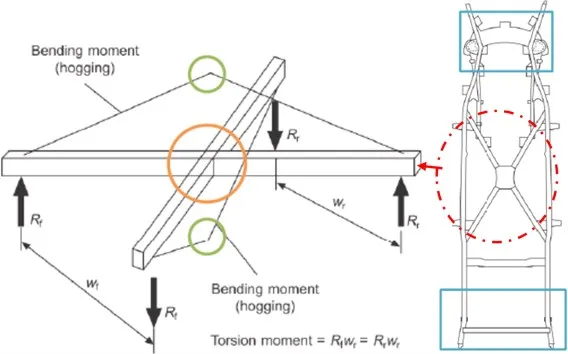

One of the fundamental and most important stage during designing process is proper develop of chassis and frame of the vehicle, especially for special heavy vehicles. Design of the vehicle chassis has to be started from analysis of load cases. There are five basic load cases to consider:

- bending case: loading in vertical plane, the x-z plane due to the weight of components distributed along the vehicle frame which cause bending about the y-axis;

- torsion case: vehicle body is subjected to a moment applied at the axle centerlines by applying upward and downward loads at each axle. These loads result in twisting action or torsion moment about the longitudinal x-axis;

- combined bending and torsion loads;

- lateral loading: generated at the tire to ground contact patch. These loads are balanced by centrifugal forces;

- fore and aft loading: generated when vehicle accelerates and decelerates inertia forces [14,15].

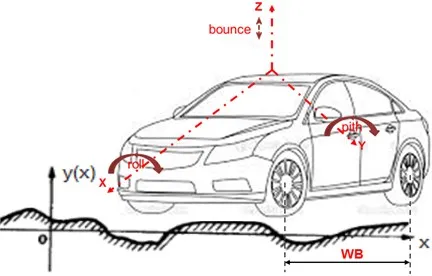

The axes of the vehicle and directions of basic movements have been depicted in Fig. 1.

Fig. 1. The axes of the vehicle and directions of basic movements [16]

An example of the worst-case loading conditions as well as overloading must be considered for the static load case. The factors usually applied to the static load case, especially for those vehicles with a long overhang containing concentrated loads (e.g., rear engine buses). Such loads result in high bending moments over the rear axle. The various dynamic conditions considered here for the determination of the axle loads are considered in [17]. If we consider the dynamic loads caused by vehicle-pavement interaction are either moving loads or random loads. There are some publications reporting number of field measurements and theoretical investigations, which have shown that vehicle vibration-induced pavement loads are moving stochastic loads [18, 19].

Also the torsion stiffness is an important characteristic in chassis design. Because of the impact on the ride safety and comfort [20]. Thus goal of design is to increase the torsion stiffness without significantly increasing the weight of the chassis.

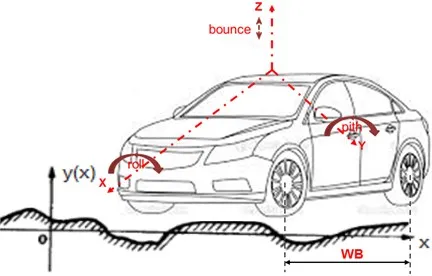

One of the most interesting methods for chassis and frame design is the SSS (Simple Structural Surfaces) method. It is a simple analytical approach for initial analyses of a preliminary design concept. The SSS method is used to analyze simple structures using thin plates as structural members. It can be considered as rigid only in its own plane. The represent of the vehicle structure by SSS have been described years ago in . Some examples have been depicted in Fig. 2, where η is the number of the plane structural elements (subassembly).

Fig. 2. The representations of the vehicle structure by SSS

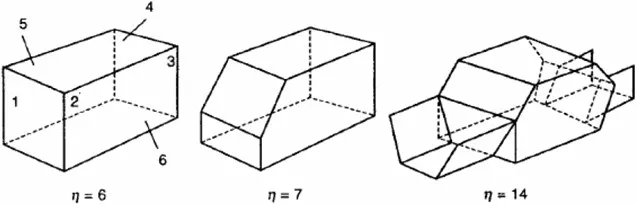

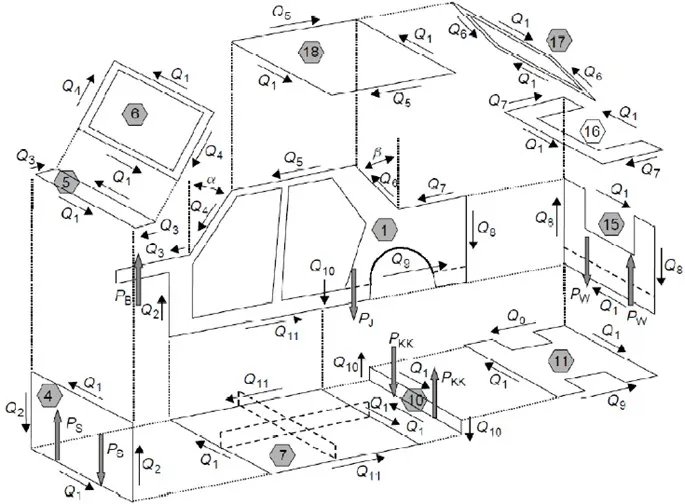

There are two key assumptions made when analyzing a structure. The first is that the structure is statically determinant . This assumption limits the accuracy, especially in vehicle design where a number of redundant structures are used. The second assumption is that a sheet is unable to react out of plane loads, it has zero stiffness to loads applied perpendicular to the surface. When analyzing a vehicle a systematic approach is used where sheets are analyzed one at a time starting with sheets containing the input loads, which were calculated separately. The end result will be the edge loads of each sheet, as labeled in the Fig. 3 . The same method can be carried out modeling of structures for commercial or special vehicle. Some example of simple SSS van structure have been depicted in Figure 4.

Fig. 3. Edge load diagram – half of the vehicle

Some disadvantages of the SSS method in vehicle design are:

- problem in the design concept,

- flexibility in the rear door frame of a simple box results in the torsion moment being carried entirely in the floor or chassis frame,

- if the surrounding frame has low stiffness the glass may be loaded excessive.

For the commercial and special vehicles the utility of the vehicle during operation is very important. It becomes an impact factor especially for special heavy vehicles, which are dedicated for specific operating conditions and defined purpose of utility. Thus there are many types of chassis. Starting from historical ladder frames used by early motor cars. These frames have carried all load but it can accommodate large variety of body shapes. It has good bending strength and stiffness but very low torsional stiffness. These frames are still used in light commercial vehicles like pick up. Other type are cruciform frames which can carry torsional loads because no elements of the frame is subjected to torsional moment. It is made of two straight beams and have only bending loads. Torque tube back bone (tube-frame) frame is made of closed box section as main back bone. Traverse beams resist lateral loads and back bone frame bending and torsion. The advantage of using tubes rather than the previous open channel sections is that they resist torsional forces better. Typical chassis for the race care is space frame, which is lightweight rigid structure constructed from interlocking struts in a geometric pattern. Beam elements carry either tension or compressive loads by the inherent rigidity of the triangular frame. In both a space frame and a tube-frame chassis, the suspension, engine, and body panels are attached to a skeletal frame of tubes, and the body panels have little or no structural function. Other modern structure types are monocoque (single-shell), punt structure, perimeter space frame, integral body structure, modern integral body-in-white.

Some examples of chassis and frames for special vehicles have been depicted in Figs. 5-8.

Fig. 4. SSS Van structure, where SSS 1-6: carry bending load, SSS 5-10: carry torsion load

Fig. 5. SSS ladder frame [1]

Fig. 6. Cruciform frame

Fig. 7. Back bone structure (Lotus) [24]

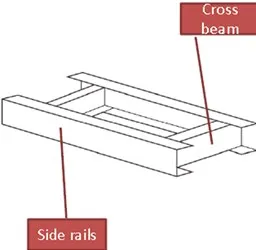

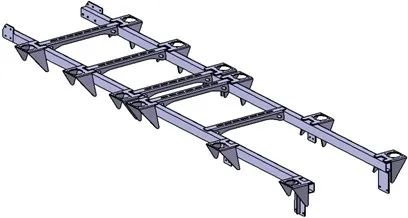

An interesting solution to extend possibilities of regular frames or chassis for specific or defined purpose and utility is intermediate frames. As the example of the intermediate frame for special vehicles operated in terrain the construction presented in Fig. 9 has been developed by PS Szcześniak company.

Fig. 8. Space-frame – Formula 1 [25]

Fig. 9. Intermediate frame – PS Szcześniak solution

The process of design of chassis and frames, especially in special heavy vehicles, is fundamental stage in total production process. Many of vehicles properties are strictly connected with the chassis or frame. Dynamic properties and static or geometric parameters of the vehicle depends on chassis or frames. Also vibration phenomena in heavy vehicles are an important issue. As far as dynamic responses isolation in cabs is well recognized for the isolation of loads there are many investigations needed. These issues are very important for vehicle designers and engineers and has to be take into focused consideration in all productions processes, especially during assumptions and constructions of chassis or frames.

The review of the solutions in constructions of the chassis and frames allows to make some assumptions for PS Szcześniak project in scope of research programme DEMONSTRATOR + Supporting scientific research and development works in demonstration scale, the title of the project is Develop High Mobility Wheeled Platform for special applications.