BASICS OF MECHANISMS

Introduction:

Definitions : Link or Element, Pairing of Elements with degrees of freedom, Grubler’s criterion (without derivation), Kinematic chain, Mechanism, Mobility of Mechanism, Inversions, Machine.

Kinematic Chains and Inversions:

Kinematic chain with three lower pairs, Four bar chain, Single slider crank chain and Double slider crank chain and their inversions.

Mechanisms:

i) Quick return motion mechanisms – Drag link mechanism, Whitworth mechanism and Crank and slotted lever mechanism

ii) Straight line motion mechanisms – Peacelier’s mechanism and Robert’s mechanism.

iii) Intermittent motion mechanisms – Geneva mechanism and Ratchet & Pawl mechanism.

iv)Toggle mechanism, Pantograph, Hooke’s joint and Ackerman Steering gear mechanism.

Terminology and Definitions-Degree of Freedom, Mobility

· Kinematics: The study of motion (position, velocity, acceleration). A major goal of understanding kinematics is to develop the ability to design a system that will satisfy specified motion requirements. This will be the emphasis of this class.

· Kinetics: The effect of forces on moving bodies. Good kinematic design should produce good kinetics.

· Mechanism: A system design to transmit motion. (low forces)

· Machine: A system designed to transmit motion and energy. (forces involved

· Basic Mechanisms: Includes geared systems, cam-follower systems and linkages (rigid links connected by sliding or rotating joints). A mechanism has multiple moving parts (for example, a simple hinged door does not qualify as a mechanism).

· Examples of mechanisms: Tin snips, vise grips, car suspension, backhoe, piston engine, folding chair, windshield wiper drive system, etc.

Key concepts:

· Degrees of freedom: The number of inputs required to completely control a system. Examples: A simple rotating link. A two link system. A four-bar linkage. A five-bar linkage.

· Types of motion: Mechanisms may produce motions that are pure rotation, pure translation, or a combination of the two. We reduce the degrees of freedom of a mechanism by restraining the ability of the mechanism to move in translation (x-y directions for a 2D mechanism) or in rotation (about the z-axis for a 2-D mechanism).

· Link: A rigid body with two or more nodes (joints) that are used to connect to other rigid bodies. (WM examples: binary link, ternary link (3 joints), quaternary link (4 joints)

· Joint: A connection between two links that allows motion between the links. The motion allowed may be rotational (revolute joint), translational (sliding or prismatic joint), or a combination of the two (roll-slide joint).

· Kinematic chain: An assembly of links and joints used to coordinate an output motion with an input motion.

· Link or element:

A mechanism is made of a number of resistant bodies outof which some may have motions relative to the others. Aresistant body or a group of resistant bodies with rigid connections preventing their relative movement is known as alink.

A link may also be defined as a member or a combination ofmembers of a mechanism, connecting other members and havingmotion relative to them, thus a link may consist of one or moreresistant bodies. A link is also known as Kinematic link or anelement.

Links can be classified into 1) Binary, 2) Ternary, 3) Quarternary, etc.

· Kinematic Pair:

A Kinematic Pair or simply a pair is a joint of two links having relative motion between them.

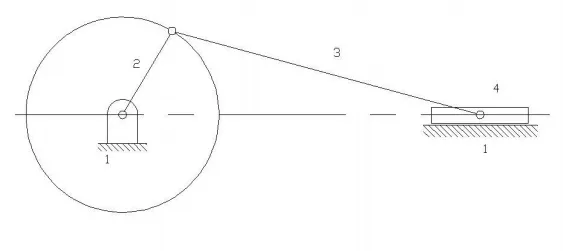

Example:

In the above given Slider crank mechanism, link 2 rotates relative to link 1 and constitutes a revolute or turning pair. Similarly, links 2, 3 and 3, 4 constitute turning pairs. Link 4 (Slider) reciprocates relative to link 1 and its a sliding pair.