Friction drives:

Friction in screw threads:

· Friction in screw and nut

· Friction in screw jack

· Problems in screw jack

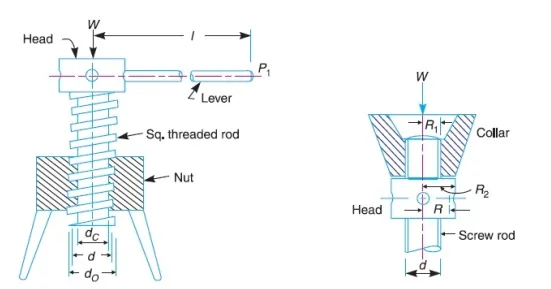

Screwjack:

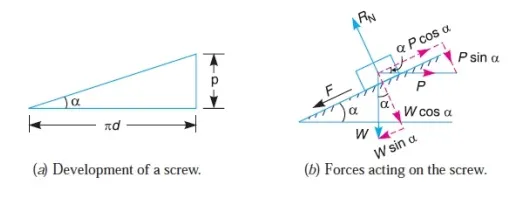

The screw jack is a device lifting loads. For lifting heavy loads by applying a comparatively smaller effort at its handle. The principle on which a screw jack works in a smaller to that of an inclined plane.

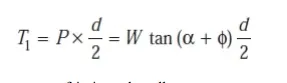

1. Torque required lifting the load by a screw jack

Let p=pitch of the screw

d =mean diameter of the screw

α= helix angle

P= effort applied at the circumference of the screw to lift the load

W=load to be lifted

µ=coefficient of the friction

tan α=p/Πd

Torque required overcoming friction between the screw and nut

The torque required to overcome friction at the collar

Total Torque required overcoming friction

If an P1 is applied at the end of a lever of arm l, then the total torque required to overcome friction must be equal to the torque applied at the end of the lever

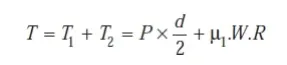

2. Torque required lower the load by a screw jack

Let p=pitch of the screw

d =mean diameter of the screw

α= helix angle

P= effort applied at the circumference of the screw to lift the load

W=load to be lifted

µ=coefficient of the friction

tan α=p/Πd

Torque required overcoming friction between the screw and nut

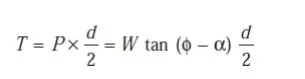

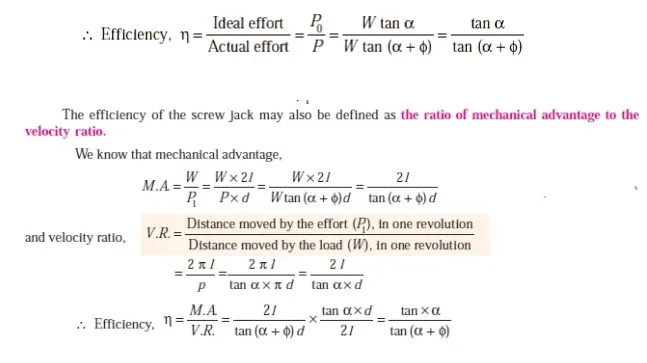

Efficiency of the screw jack:

The efficiency of the screw jack may b defined as the ratio between the ideal efforts to actual effort.

Self locking and over hauling of screws

Torque required to lower the load

In the above expressions ,if ϕ< α ,then the torque required to lower the load will be negative ,the load will start moving downward without application of force, such a condition is known as overhauling of screw.

If ϕ> α ,then the torque required to lower the load will be positive ,indicating that an efforts applied lower the load , such a condition is known as self locking of screw