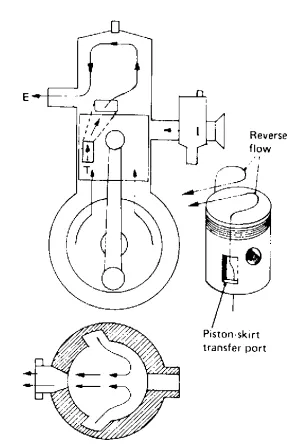

Reverse-flow (Schnuerle) scavenging

To improve scavenging efficiency, a loop-scavenging system which became known as the reverse-flow or (after its inventor, Dr E. Schnuerle) as the Schnuerle scavenging system was developed (Fig. Below). This layout has a transfer port on each side of the exhaust port, and these direct the scavenging charge mixture in a practically tangential direction towards the opposite cylinder wall. The two separate columns of the scavenging mixture meet and merge together at this wall to form one inward rising flow which turns under the cylinder head and then flows down on the entry side, thus forming a complete loop. With this form of porting, turbulence and intermixing of fresh fuel mixture with residual burnt gases will be minimal over a wide range of piston speeds.

Reverse flow or Schnuerle scavenging.

Note that in this particular design the charge mixture is transferred through ports formed in the piston skirt. Alternatively, extended transfer passages may be preferred so that the piston skirt plays no part in the timed transfer.