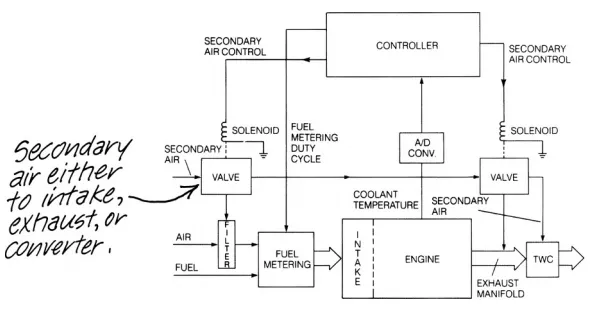

Integrated engine control system

Each control subsystem for fuel control, spark control, and EGR has been discussed separately. However, a fully integrated electronic engine control system can include these subsystems and provide additional functions. (Usually the flexibility of the digital control system allows such expansion quite easily because the computer program can be changed to accomplish the expanded functions.) Several of these additional functions are discussed in the following.

Secondary air management

Secondary air management is used to improve the performance of the catalytic converter by providing extra (oxygen-rich) air to either the converter itself or to the exhaust manifold. The catalyst temperature must be above about 200C to efficiently oxidize HC and CO and reduce NOx. During engine warm-up when the catalytic converter is cold, HC and CO are oxidized in the exhaust manifold by routing secondary air to the manifold. This creates extra heat to speed the warm-up of the converter and EGO sensor, enabling the fuel controller to go to the closed-loop mode more quickly.

The converter can be damaged if too much heat is applied to it. This can occur if large amounts of HC and CO are oxidized in the manifold during periods of heavy loads, which call for fuel enrichment, or during severe deceleration. In such cases, the secondary air is directed to the air cleaner, where it has no effect on exhaust temperatures.

After warm-up, the main use of secondary air is to provide an oxygen-rich atmosphere in the second chamber of the three-way catalyst, dual-chamber converter system. In a dual-chamber converter, the first chamber contains rhodium, palladium, and platinum to reduce NOx and to oxidize HC and CO. The second chamber contains only platinum and palladium. The extra oxygen from the secondary air improves the converter’s ability to oxidize HC and CO in the second converter chamber.

The computer program for the control mode selection logic can be modified to include the conditions for controlling secondary air. The computer controls secondary air by using two solenoid valves similar to the EGR valve. One valve switches air flow to the air cleaner or to the exhaust system. The other valve switches air flow to the exhaust manifold or to the converter. The air routing is based on engine CT and air/fuel ratio. The control system diagram for secondary air is shown in Fig.