EGR control

A second electronic engine control subsystem is the control of exhaust gas that is recirculated back to the intake manifold. Under normal operating conditions, engine cylinder temperatures can reach more than 3,0000F. The higher the temperature, the more is the chance that the exhaust will have NOx emissions. A small amount of exhaust gas is introduced into the cylinder to replace normal intake air. This results in lower combustion temperatures, which reduces NOx emissions.

The control mode selection logic determines when EGR is turned off or on. EGR is turned off during cranking, cold engine temperature (engine warm-up), idling, acceleration, or other conditions demanding high torque.

Since EGR was first introduced as a concept for reducing NOx exhaust emissions, its implementation has gone through considerable change. There are in fact many schemes and configurations for EGR realization. We discuss here one method of EGR implementation that incorporates enough features to be representative of all schemes in use today and in the near future.

Fundamental to all EGR schemes is a passageway or port connecting the exhaust and intake manifolds. A valve is positioned along this passageway whose position regulates EGR from zero to some maximum value. Typically, the valve is operated by a diaphragm connected to a variable vacuum source. The controller operates a solenoid in a periodic variable-duty-cycle mode. The average level of vacuum on the diaphragm varies with the duty cycle. By varying this duty cycle, the control system has proportional control over the EGR valve opening and thereby over the amount of EGR.

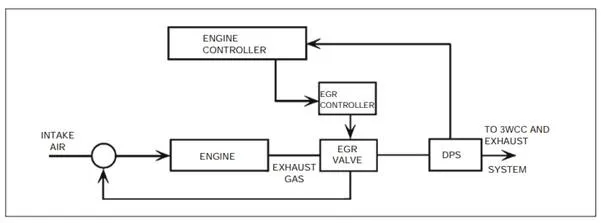

In many EGR control systems the controller monitors the DP between the exhaust and intake manifold via a differential pressure sensor (DPS). With the signal from this sensor the controller can calculate the valve opening for the desired EGR level. The amount of EGR required is a predetermined function of the load on the engine (i.e., power produced).

A simplified block diagram for an EGR control system is depicted in Fig. a. In this figure the EGR valve is operated by a solenoid-regulated vacuum actuator (coming from the intake). The engine controller determines the required amount of EGR based on the engine operating condition and the signal from the DPS between intake and exhaust manifolds. The controller

EGR control

then commands the correct EGR valve position to achieve the desired amount of EGR.