Hybrid Drive Trains | Hybrid Vehicles

Hybrid vehicles

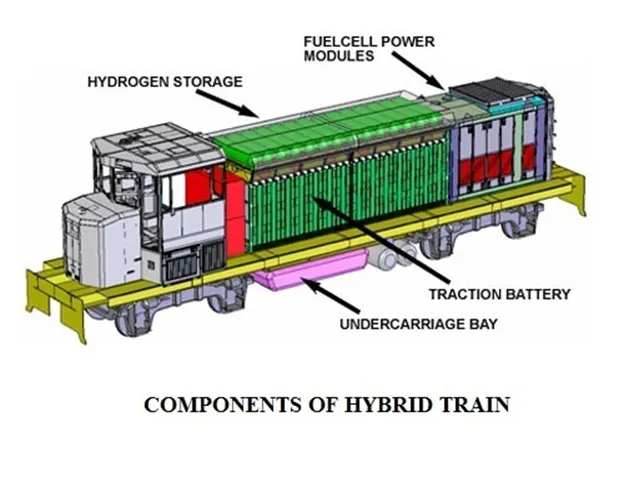

The term Hybrid drive denotes such vehicle drives with more than one drive source. Hybrid drives can incorporate several similar or dissimilar types of energy stores and/or power converters.

The goal of the hybrid drive developments is to combine different drive components, such that the advantages of each are utilized under varying operating conditions in such a manner that the overall advantages outweigh the higher technical and cost outlay associated with hybrid drives.

Hybrid drive trains

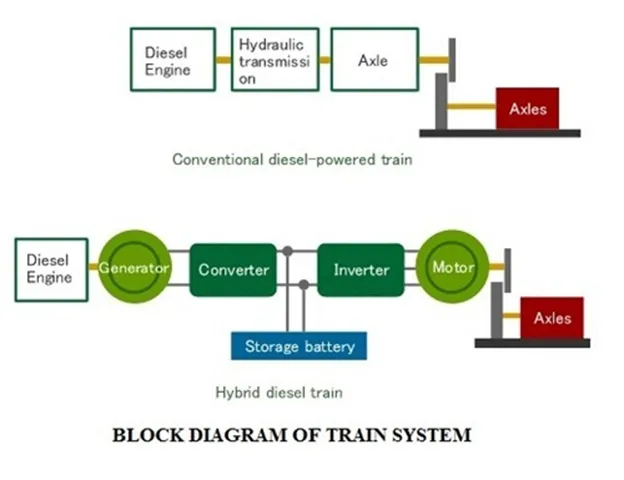

Hybrid drive trains are broadly classified into series and parallel depending on the configuration of the power source.

Series

In a series drive train, only the electric power is coupled to the wheels. The second power source converts fuel energy into electric power. This electric power is then passed in a series fashion through the electric drive and motor to the wheels. Typically an IC engine is coupled to an alternator to provide the fuel based electric power. The engine alternator combination is often referred to as an auxiliary power unit.

Series hybrid engines have the following characteristics

The engine and the energy storage devices are closely coupled. More efficient, satisfying light load power demands.

Parallel

In the parallel hybrid drive trains, two power sources operate in parallel to propel the vehicle. Power from the electric motor and internal combustion engine are combined via the vehicle transmission to satisfy the road power demand.

Parallel hybrid engines have the following characteristics

Drive train losses between the engine and the engine and the road are minimal. Generally more efficient and satisfying high power demand.

Parallel hybrids have speed coupling between the road and the engine. Series hybrids do not have speed coupling. Both series and parallel hybrids can be operated with engine to road power decoupling. Both parallel and series hybrids can be implemented with large engines and small energy storage or vice versa.

Series and parallel combined system

This combined system called the dual system having a generator and a motor, features characteristics of both the series and parallel systems, and the following systems are possible.

Switching system

This implies the application and the release of the clutch switches between the series and parallel system. For driving by the series system, the clutch is released, separating the engine and the generator from the driving wheels. For driving with the parallel system, the clutch is engaged, connecting the engine and the driving wheels.

Since city driving requires low loads for driving and low emission, the series system is selected with the clutch released. For high speed driving where the series system would not work efficiently due to higher drive loads and consequently higher engine output is required, the parallel system is selected with the clutch applied.

Split system

This system acts as the series and parallel systems at all times. The engine output energy is split by the planetary gear into the series path and the parallel path. It can control the engine speed under variable control of the series path by the generator while maintaining the mechanical connection of the engine and the driving wheels through the parallel path.