Durability Analysis

Automotive††††††††††††††††††††††

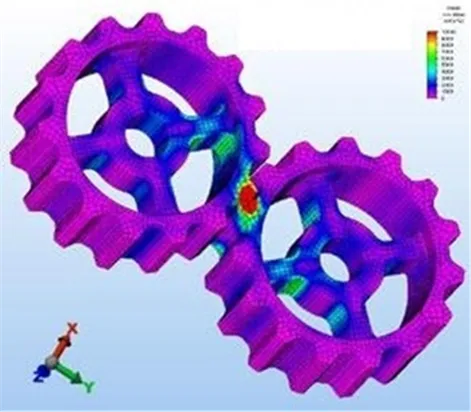

● Design more reliable transmissions, drivelines and axles

● View the whole gearbox as an interacting and flexible system

● Predict gear, bearing and shaft life-times in the design concept phase

● Accurately and efficiently compare complex gearbox arrangements or concepts such as AMT, DCT, Hybrid and CVT

● Reduce gearbox weight by using component strength

● Minimize noise and vibration by influencing the transmission error

● Identify the weak points in the whole system under realistic load conditions

● Consider the impact of manufacturing tolerances in the concept design phase

● Improve the bearing choice by unique accurate prediction of bearing behavior

● Interact with dynamic solutions for your full vehicle design

● Predict the affects of generators/e-engines on the gears and its components in your hybrid system

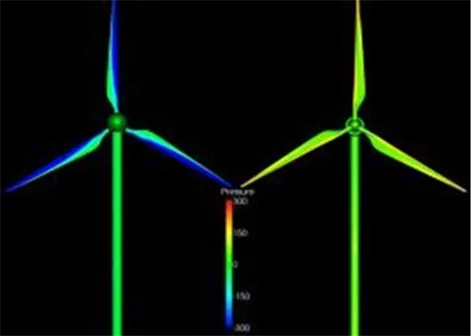

Wind turbine

● Understand and benchmark operating load and extreme load scenarios

● Design gearboxes to meet life-time targets

● View the gearbox as one complete system, without the need for sectioning and sectional boundary conditions

● Analyze the behavior of complex planetary systems within the whole system

● Accurately predict loads, deflections and interactions of all components

● Calculate detailed bearing behavior to identify excessive loads

● Direct loads or reduce misalignments to improve the system quality

● Predict load sharing in the fully flexible system instead of assuming load sharing factors

● Reduce weight and cost without reducing component lifetime

● Minimize noise pollution caused by transmission error

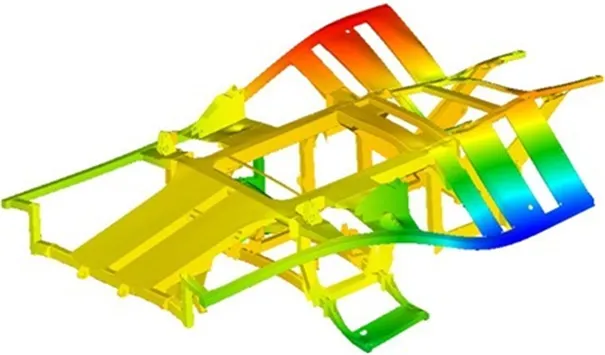

Aerospace

● Improve reliability for critical parts

● Reduce gearbox weight

● Predict bearing behavior under extreme load and climate conditions

● Optimize gearbox size

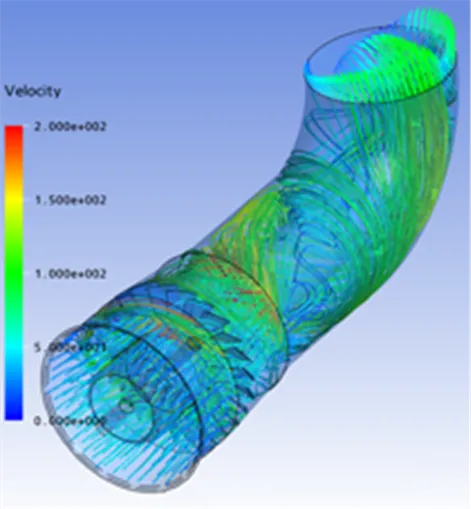

Off-highway

● Design heavy duty transmissions

● Accurately represent multi-gear mesh situations

● Optimize gearbox weight without compromising durability

● Predict system behavior under misuse conditions

● Compare different lubrication situations

● Precisely define micro-geometries to avoid edge-loading of teeth under extreme load conditions

● Consider split-torque system load

Industrial equipment

● Design for improved reliability in process machinery, material handling, power take offs, speed reducers and production line equipment

● Improve accuracy of high precision machinery by understanding and predicting system and component deflections

● Reduce failures in gears and bearings due to precise prediction of misalignments

Consumer and office appliance

● Optimize weight and size of power tools, food processors, washing machines, printers and photocopiers

● Improve product quality by reducing unwanted deflections

● Predict changes of working accuracy over a productís life

● Design casings that fulfill the requests for look and function simultaneously without wasting material

● Consider new materials for new or existing product concepts

● Create technical documentation for certification