Hydraulic Hybrid Vehicles

Introduction To Hydraulic Hybrid Vehicles:

Hybrid vehicles use two sources of power to drive the wheels. In a hydraulic hybrid vehicle (HHV) a regular internal combustion engine and a hydraulic motor are used to power the wheels.

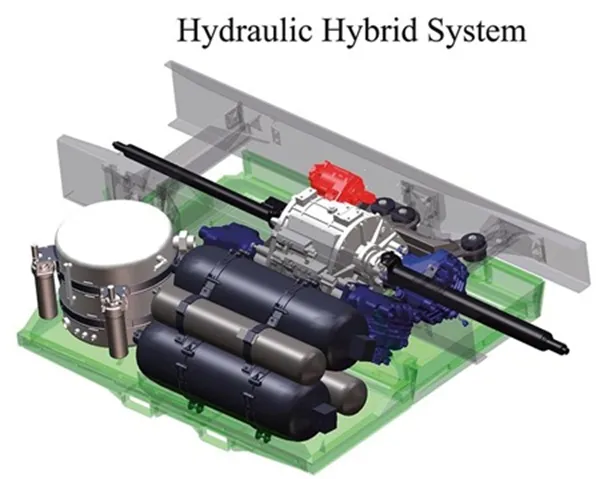

Hydraulic hybrid systems consist of two key components:

● High pressure hydraulic fluid vessels called accumulators, and

● Hydraulic drive pump/motors.

Working of Hydraulic Hybrid Systems:

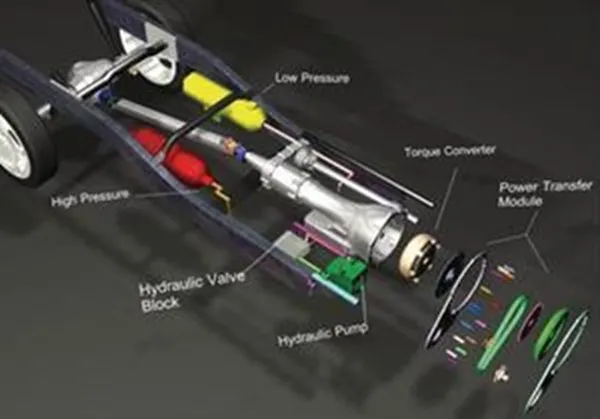

The accumulators are used to store pressurized fluid. Acting as a motor, the hydraulic drive uses the pressurized fluid (Above 3000 psi) to rotate the wheels. Acting as a pump, the hydraulic drive is used to re-pressurize hydraulic fluid by using the vehicle’s momentum, thereby converting kinetic energy into potential energy. This process of converting kinetic energy from momentum and storing it is called regenerative braking.

The hydraulic system offers great advantages for vehicles operating in stop and go conditions because the system can capture large amounts of energy when the brakes are applied.

The hydraulic components work in conjunction with the primary. Making up the main hydraulic components are two hydraulic accumulator vessels which store hydraulic fluid compressing inert nitrogen gas and one or more hydraulic pump/motor units.

The hydraulic hybrid system is made up of four components.

● The working fluid

● The reservoir

● The pump or motor

● The accumulator

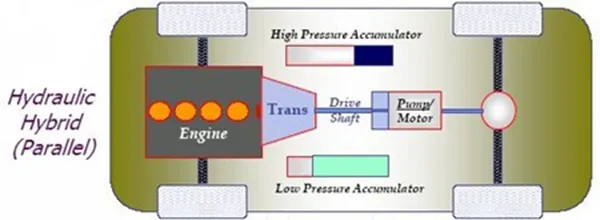

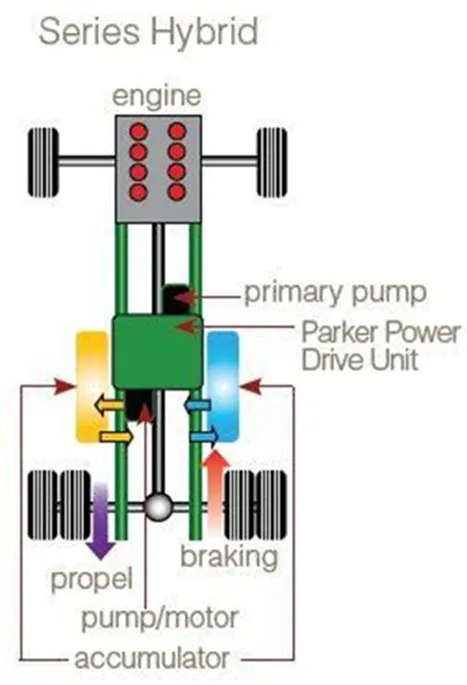

The pump or motor installed in the system extracts kinetic energy during braking. This in turn pumps the working fluid from the reservoir to the accumulator, which eventually gets pressurized. The pressurized working fluid then provides energy to the pump or motor to power the vehicle when it accelerates. There are two types of hydraulic hybrid systems – the parallel hydraulic hybrid system and the series hydraulic hybrid system. In the parallel hydraulic hybrid, the pump is connected to the drive-shafts through a transmission box, while in series hydraulic hybrid, the pump is directly connected to the drive-shaft.

There are two types of HHVs:

● Parallel and

● Series.

Parallel Hydraulic Hybrid Vehicles:

In parallel HHVs both the engine and the hydraulic drive system are mechanically coupled to the wheels. The hydraulic pump-motor is then integrated into the driveshaft or differential.

Series Hydraulic Hybrid vehicles:

Series HHVs rely entirely on hydraulic pressure to drive the wheels, which means the engine does not directly provide mechanical power to the wheels. In a series HHV configuration, an engine is attached to a hydraulic engine pump to provide additional fluid pressure to the drive pump/motor when needed.

Advantages:

● Higher fuel efficiency. (25-45 percent improvement in fuel economy)

● Lower emissions. (20 to 30 percent)

● Reduced operating costs.

● Better acceleration performance.