Idling Devices Of Automobile | Anti-Dieseling Device

Idling devices in carburetor

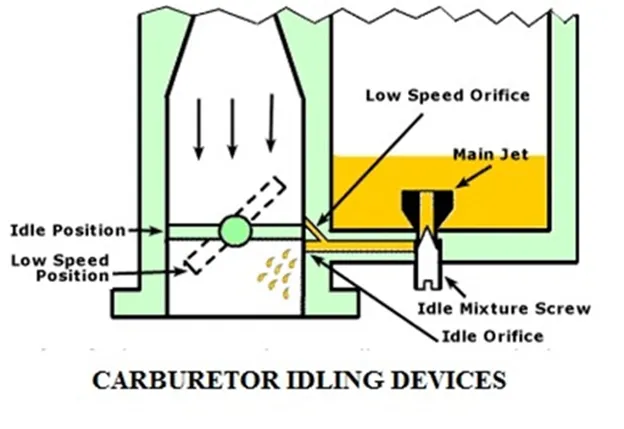

During idling, the throttle plate is almost in the closed position. Then the mass rate of air flow through the venture is small. Hence, the vacuum or depression produced at the venture is also small. With this small depression, no fuel can issue from the fuel orifice. Hence, an idling device is incorporated in the carburetor unit.

The engine idling device can be seen in the picture. This device utilizes the large vacuum that prevails at the edge of the throttle plate for effecting fuel supply, when the throttle plate is almost in the closed position.

The required idling mixture strength can be obtained by adjusting the idling air screw. The quantity of the mixture supplied to the engine is controlled by the throttle plate setting. This setting decides the extent of closure of the inlet passage by the throttle plate.

The idling device operates at maximum capacity when the throttle plate is almost in the closed position. The effectiveness of the idling device gradually diminishes, as the throttle plate is being opened.

When the throttle plate is wide open, the depression felt at the idling get is extremely small. This small depression is not capable of raising the fuel through the large height in the idling jet upto the discharge point. Now the maximum depression shifts to the venture throat. As such the main orifice starts supplying the fuel.

Anti-dieseling device

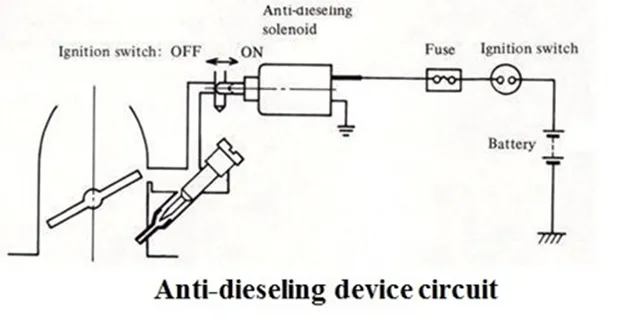

A spark ignition engine sometime continues to run for a very small period, even after the ignition is switched off. This phenomena is called dieseling or after running. This causes wastage of fuel and pollution.

Some modern cars have the anti-dieseling system as shown in the picture. This system has a solenoid valve operated idling circuit. When the ignition switch is turned on, current flows in the coil of the solenoid valve and thereby generates a force. This force pulls a needle valve and opens the passage for slow speed mixture. When the ignition switch is turned off, the magnetic force disappears. Then the needle valve goes to the original position immediately by the action of the spring in the solenoid valve. By this way, the slow speed mixture passage is cut off. Hence, the engine stops and the fuel wastage are also eliminated.

Hot idling compensator: Some modern cars have this system in the carburetor unit. Under certain extremely hot operating conditions there is a tendency for the idling mixture to become too rich. This causes idling instability. The hot idling compensator system incorporates a bimetallic value which admits air directly into the manifold in correct quantity when needed. Thus the mixture richness is adjusted and stable idling is ensured.