7 Important features of DCS

• To handle complex processes:

In factory automation structure, PLC-Programming Logic Controller is used to control and monitor the process parameters at high speed requirements. However due to limitation of number of I/O devices, PLC’s cannot handle complex structure.

Handling Complex Processes

Hence DCS is preferred for complex control applications with more number of I/O’s with dedicated controllers. These are used in manufacturing processes where designing of multiple products are in multiple procedures such as batch process control.

System redundancy:

System Redundancy

DCS facilitates system availability when needed by redundant feature at every level.

Resuming of the steady state operation after any outages, whether planned or unplanned is somewhat better compared to other automation control devices.

Redundancy raises the system reliability by maintaining system operation continuously even in some abnormalities while system is in operation.

Lot of Predefined function blocks:

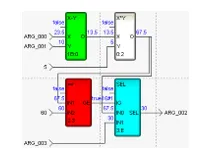

Predefined Function block

DCS offers many algorithms, more standard application libraries, pre-tested and pre-defined functions to deal with large complex systems. This makes programming to control various applications being easy and consuming less time to program and control.

Powerful programming languages:

It provides more number of programming languages like ladder, function block, sequential, etc for creating the custom programming based on user interest.

More sophisticated HMI:

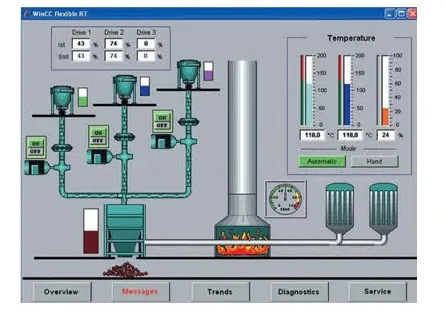

Similar to the SCADA system, DCS can also monitor and control through HMI’s (Human Machine Interface) which provides sufficient data to the operator to charge over various processes and it acts as heart of the system. But this type of industrial control system covers large geographical areas whereas DCS covers confined area.

Sophisticated HMI

DCS completely takes the entire process plant to control room as a PC window. Trending, logging and graphical representation of the HMI’s give effective user interface. Powerful alarming system of DCS helps operators to respond more quickly to the plant conditions

Scalable platform:

Structure of DCS can be scalable based on the number I/O’s from small to large server system by adding more number of clients and servers in communication system and also by adding more I/O modules in distributed controllers.

System security:

Access to control various processes leads to plant safety. DCS design offers perfect secured system to handle system functions for better factory automation control. Security is also provided at different levels such as engineer level, entrepreneur level, operator level, etc.

Application of Distributed Control System

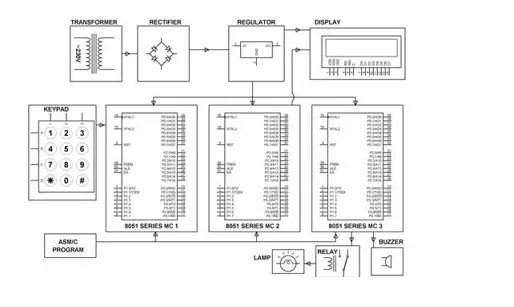

DCS system can be implemented in a simple application like load management using network of microcontrollers.

Application of DCS

Here the input is given from a keypad to a microcontroller, which communicates with the other two microcontrollers. One of the microcontrollers is used to display the status of the process as well as the loads, while the other microcontroller controls the relay driver. The relay driver in turn drives the relay to operate the load.