What is Distributed Control System

Distributed Control System is a specially designed control system used to control complex, large and geographically distributed applications in industrial processes. In this, controllers are distributed throughout the entire plant area.

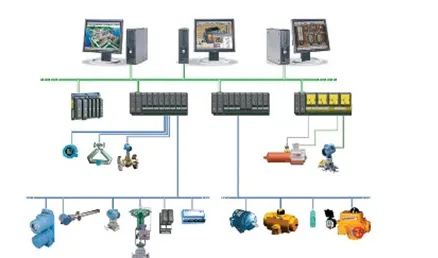

These distributed controllers are connected to both field devices and operating PCs through high speed communication networks as shown in figure.

Discrete Field devices such as sensors and actuators are directly connected to input and output controller modules through communication bus. These field devices or smart instruments are capable of communicating with PLC’s or other controllers while interacting with real world parameters like temperature, pressure, etc.

DCS Architecture

Controllers are distributed geographically in various section of control area and are connected to operating and engineering stations which are used for data monitoring, data logging, alarming and controlling purpose via another high speed communication bus.

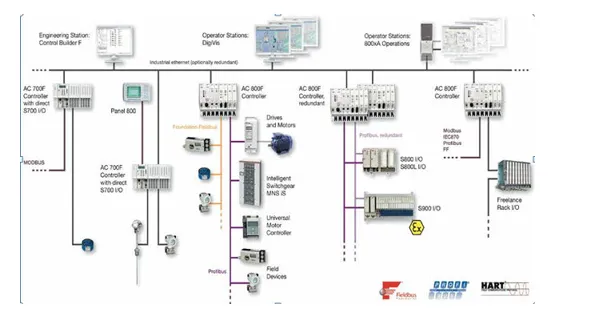

These communication protocols are of different types such as foundation filed bus, HART, Profibus, Modbus, etc. DCS provides information to multiple displays for user interface.

4 Basic Elements of Distributed Control System

Distributed Control System continuously interacts with the processes in process control applications ones it gets instruction from the operator. It also facilitates to variable set points and opening and closing of valves for manual control by the operator. Its human machine interface (HMI), face plates and trend display gives the effective monitoring of industrial processes.

Elements of DCS

Engineering PC or controller

This controller is the supervisory controller over all the distributed processing controllers. Control algorithms and configuration of various devices are executed in this controller. Network communication between processing and engineering PC can be implemented by simplex or redundant configurations.

Distributed controller or Local control unit

It can be placed near to field devices (sensors and actuators) or certain location where these field devices are connected via communication link. It receives the instructions from the engineering station like set point and other parameters and directly controls field devices.

It can sense and control both analog and digital inputs / outputs by analog and digital I/O modules. These modules are extendable according to the number of inputs and outputs. It collects the information from discrete field devices and sends this information to operating and engineering stations.

In above figure AC 700F and AC 800Fcontrollers acts as communication interface between field devices and engineering station. Most of the cases these act as local control for field instruments.

Operating station or HMI

It is used to monitor entire plant parameters graphically and to log the data in plant database systems. Trend display of various process parameters provides the effective display and easy monitoring.

These operating stations are of different types such as some operating stations (PC’s) used to monitor only parameters, some for only trend display, some for data logging and alarming requirements. These can also be configured to have control capabilities.

Communication media and protocol

Communication media consists of transmission cables to transmit the data such as coaxial cables, copper wires, fiber optic cables and sometimes it might be wireless. Communication protocols selected depends on the number of devices to be connected to this network.

For example, RS232 supports only for 2 devices and Profibus for 126 devices or nodes. Some of these protocols include Ethernet, DeviceNet, foundation filed bus, modbus, CAN, etc.

In DCS, two or more communication protocols are used in between two or more areas such as between field control devices and distributed controllers and other one between distributed controllers and supervisory control stations such as operating and engineering stations.