What Is the Working Principle of A CNC

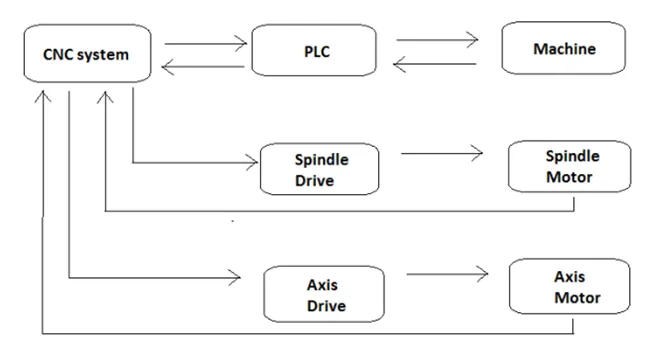

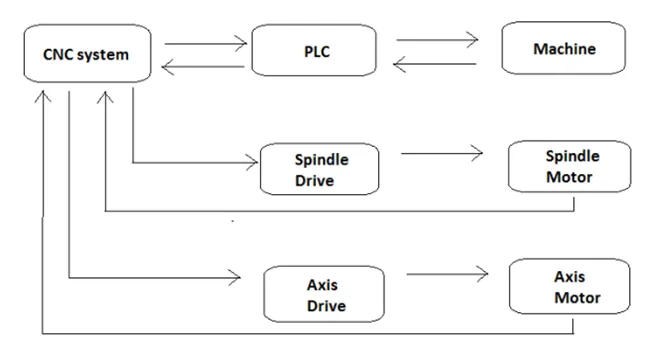

In CNC system a dedicated computer is used to perform all the essential functions as per the executive program stored in the computer memory. The system directs commands to servo drives to drive the servo motor & other output devices like relays, solenoids, etc. to initiate the operations such as motor starting & stopping, coolant on & off, tool changing, pallet changing, etc. and other miscellaneous functions.

Once the system gives, it becomes necessary to ensure that the particular function has been completed. This is done by “Feed Back Devices.” Continuous feedback device like linear scale, encoder, resolver, etc. are used as position feedback of the motor. Some sensors like proximity switch, limit switch, pressure switch, flow switch, and float switch, etc. are used as feedback devices to monitor the different operations. Thus all operations of the CNC machine are monitored continuously with appropriate feedback devices. So that CNC system is called as “Closed Loop” system. In case of failure in any failure feedback, the system generates a “Fault Message.”

· Movement of X, Y, Z axis are controlled by a motor which supplies either Alternating current or Direct current.

· Movement of the machine is done by giving commands.

· All the operations are carried out by codes like speed, feed, depth of cut, etc.

· For each operation separate code is available.

· The warning system is available to save guard the various operations and components.