3-CNC Control - Open and Closed Loop

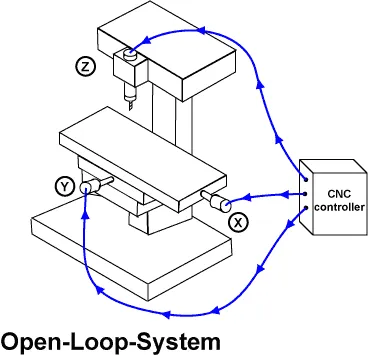

CNC systems require motor drives to control both the position and the velocity of the machine axes. Each axis must be driven separately and follow the command signal generated by the NC control. There are two ways to activate the servo drives: the open-loop system and the closed-loop system.

Open Loop - Programmed instructions are fed into the controller through an input device. These instructions are then converted to electrical pulses (signals) by the controller and sent to the servo amplifier to energize the servo motors. The cumulative number of electrical pulses determines the distance each servo drive will move, and the pulse frequency determines the velocity.

The primary drawback of the open-loop system is that there is no feedback system to check whether the program position and velocity has been achieved. If the system performance is affected by load, temperature, humidity, or lubrication then the actual output could deviate from the desired output.

For these reasons, the open-loop system is generally used in point-to-point systems where the accuracy requirements are not critical. Very few, if any, continuous-path systems utilize open-loop control.

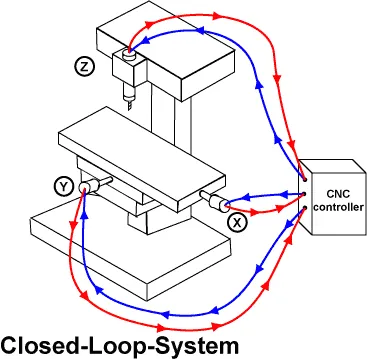

Closed Loop - The closed-loop system has a feedback subsystem to monitor the actual output and correct any discrepancy from the programmed input. The feedback system could be either analog or digital. The analog systems measure the variation of physical variables such as position and velocity in terms of voltage levels. Digital systems monitor output variations by means of electrical pulses

Closed-loop systems are very powerful and accurate because they are capable of monitoring operating conditions through feedback subsystems and automatically compensating for any variations in real-time.

Most modern closed-loop CNC systems are able to provide very close resolution of 0.0001 of an inch. Closed-looped systems would, naturally, require more control devices and circuitry in order for them to implement both position and velocity control. This, obviously, makes them more complex and more expensive than the open-loop system. A closed/open comparison is shown below