What is Electrical Discharge Machining and how does it work?

Electrical discharge machining, or EDM, is a non-traditional method in which material is removed from a workpiece using thermal energy. Much like processes such as laser cutting, EDM does not need mechanical force in the removal process. This is the reason why it is considered non-traditional contrary to, for example, the processing with cutting tools.

In tool and mould making, EDM is very popular due to its applicability especially for hard materials like titanium or for particularly complex shapes that are hard to achieve with milling.

The Ecyclopædia Britannica gives a short explanation of EDM:

“EDM involves the direction of high-frequency electrical spark discharges from a graphite or soft metal tool, which serves as an electrode, to disintegrate electrically conductive materials such as hardened steel or carbide.”

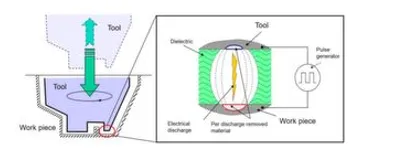

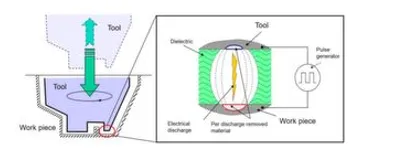

To put it more simply, electrical discharge machining is a manufacturing process that precisely removes material from conductive materials using an electrode. Similar to pushing a form into soft material, the electrode leaves a negative imprint in the workpiece. The physical process is a little more complicated: In a small gap between workpiece and electrode, a discharge occurs that removes material through melting or vaporizing. For this process, the electrode and the workpiece have to be submerged in a dielectric fluid.

The electrode tool is lowered into the workpiece (left). In the small gap between tool and workpiece, a discharge occurs that removes material (right). (Source: OPS Ingersoll)

The principle behind this process is the ability of controlled electric sparks to erode material. The workpiece and electrode do not touch during this porcess. In between is a gap that is roughly as thick as a human hair. The amount of removed material with a single spark is small, yet the discharge occurs roughly several 100,000 times a second.

While the electrode is moved closer to the workpiece, the electric field in the gap, also known as spark gap, increases until it reaches the breakdown volume. For this process, it is necessary that the fluid in which this discharge occurs is not conductive, or dielectric. The discharge causes strong heating of the material, melting away small amounts of material. This excess material is removed with the steady flow of the dielectric fluid. The liquid is also useful for cooling during the machining. Moreover, it is necessary for controlling the sparks.