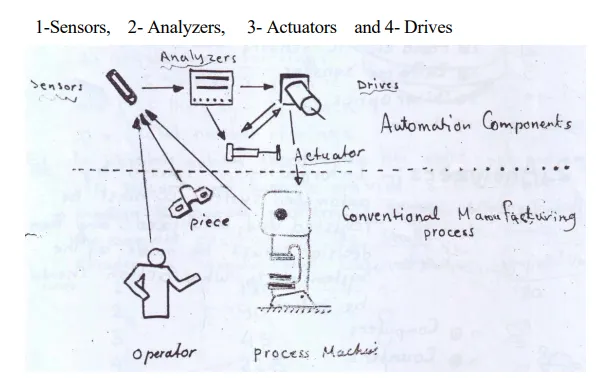

Building Blocks of Automation

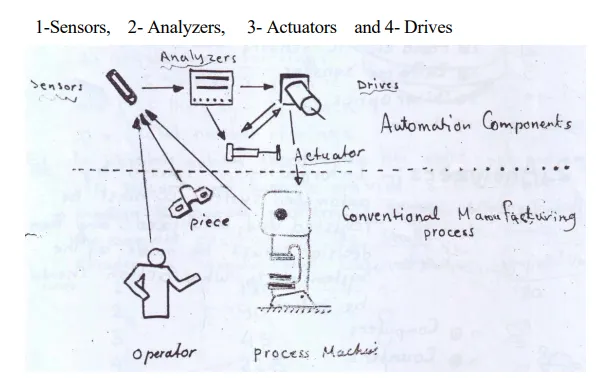

Manufacturing systems can generally be classified as fixed (hardware) or flexible (software). These classifications are normally bestowed on both the processing equipment (machine tools, welders, and so on) and the material handling system that integrates the processes. Each process or machine usually consists of dozens of mechanisms that create the required relative motion to complete an activity. These mechanisms include cams, ways and slides, pistons (pneumatic or hydraulic), vibratory devices. push rods, and screw mechanisms. Each of these mechanisms have particular characteristics that allow them to be coupled together to amplify force or speed and create/convert linear or rotary motion. When these mechanisms are mechanically fastened on a base .relative to each other in order to perform a specific task. An automated manufacturing system consists of a collection of these automatic or semiautomatic machines linked together by an "intra-system" material-handling system. These automated systems have been used to produce machined components, assemblies, electrical components, food products, chemical products, and so on. Automation is the process of controlling manufacturing systems to perform repetitive operations with a minimum of human intervention. The object of automation is to make the best use of available resources, material, money and machines; its goals being the same as in mechanization. The human workers function is limited to machine supervisory control, corrective adjustment, and retooling of the automated machine for product changes. Flexible automation first appeared in the early 1950s -with the introduction of numerically controlled (NC) machine tools. Later, NC machines evolved into computer numerical control (CNC) machines in which each machine had a small digital computer, usually a microcomputer, as one of its components. The basic components of automation as primarily belonging to one of the following four classes: