Tensioning

There is a popular misconception that the harder the cleaner is pressing against the belt, the better it will clean. However, too much pressure can force the tip away from the belt and leave a small gap, leading to hydroplaning. In addition, material wedged between the blade tip and belt can prematurely wear both the blade and belt.

As the urethane wears, the blade’s surface area increases, causing a reduction in blade-to-belt pressure and making it less efficient. Therefore, most mechanically tensioned systems require periodic adjustment (retensioning) to deliver the consistent pressure needed for effective carryback removal.

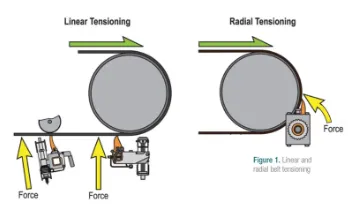

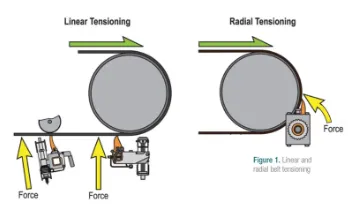

Linear-tensioned cleaners are pushed up (in a line) against the belt, and radially tensioned cleaners are installed with a mainframe as an axis and rotated into position. In addition, some hybrid systems incorporate vertical tensioning with a radial relief mechanism.

Linear-adjusted cleaners generally require access to both sides to provide balanced pressure. Radialadjusted cleaners have several practical advantages. They are easier to install and rotate away from the belt to absorb the shock of belt motion and splice passage. When designed with a specially engineered curved blade, known as CARP (constant angle radial pressure), the contact angle and surface area are minimized as the blade wears, maintaining effectiveness throughout the cleaner’s service life.