Belt Trippers Vs. Plows

Whether its stacking material in a warehouse, or removing rejected material from a process system, a tripper or a plow may be just the piece of equipment you are looking for. Belt trippers and plows function as add-ons to troughed belt conveyors in order to increase the flexibility of a handling system. Both pieces of equipment work as auxiliary material discharge systems, allowing material to be released before the head pulley. This similarity in objective has caused some confusion regarding which piece of equipment will best suit a given application. And while trippers and plows can generally be placed in the same classification, a more in-depth explanation reveals that they perform very differently. In order to know if either piece of equipment will be beneficial for your process system, you first need to understand the basic function of each.

BELT TRIPPERS

A traveling belt tripper, when integrated into a standard troughed belt conveyor, creates a more dynamic material handling system; a system that has the ability to discharge material along the entire length of the conveyor, as well as at the head pulley. Belt trippers work by redirecting the conveyor belting through several sets of pulleys to recreate a standard conveyor discharge function, or a “trip” point, that diverts the material to the desired location. Material can be discharged either continuously, or at pre-designated locations, which allows for layer stacking, or multiple silo/bunker filling. Additionally, a diverter system can be added to the belt tripper’s discharge chute. This system increases the belt tripper’s versatility, as it allows for material to be released on either side of the conveyor, or directly back onto the belt. The material diverted back onto the belt can then be released at the head pulley of the conveyor.

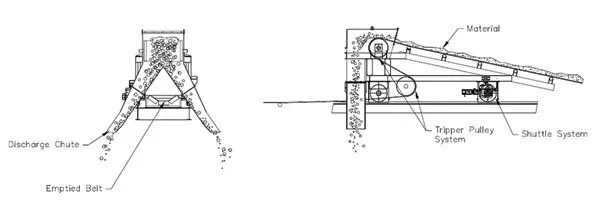

As shown in the diagram below, the loaded conveyor belt is transferred up a slight incline where it is emptied into a discharge system; this can include: double chute (shown), single chute, screw conveyor, or other discharge methods. After the material has been emptied off of the belt, the belt tripper re-aligns the belting on the stationary idlers and continues to operate as a standard trough conveyor.

Belt trippers are designed with multiple pulleys in order to eliminate any premature wear on the conveyor belting due to the use of flattening or scraping systems. FEECO belt trippers can be set to travel automatically, or be controlled remotely by an operator.

BELT PLOWS

A belt plow is a simplified way to create fixed discharge points in a troughed belt conveyor system. While belt plows work as an auxiliary material discharge system much like a belt tripper, there are several drawbacks to plows when compared to trippers.

First, the use of a belt plow offers reduced mobility of the discharge locations; the locations are locked in place and changing them would require equipment modifications. Secondly, the plows require a flat surface to be effective at removing material from the conveyor; this not only puts increased wear on the belt, but also eliminates the advantages of the troughed sidewalls. Lastly, because the plows simply push material off the belt, any large aggregates or abrasive material being handled may cause premature wear on the conveyor belting and plow blade.

Even though belt plows make for a less versatile auxiliary discharge component, they are still useful in some situations. For example, with free flowing materials, belt plows function well as part of a material redirection or rejection system. They can also be utilized for filling multiple storage hoppers, while, much like a belt tripper, still allowing for the ability to function as a standard troughed belt conveyor. The conveyor depicted below shows two belt plows that divert material into two separate storage silos (this same scenario can be used to transfer material to another belt conveyor that may be a part of a different processing system). The conveyor belting travels through a flattening structure, transforming the belt from its troughed U-shape to a flat surface, so the plow blades can effectively clear the material. Due to this relatively complex flattening process, all conveyors with a belt plow system are custom designed and built to the customer’s requirements. They are then assembled and tested at FEECO to ensure there are no interferences that could cause damage or unnecessary wear. A new belt plow may not integrate well into existing equipment as a single component. In this case, a new section of conveyor, with the belt plow system (plow(s) and flattening rails) would need to be designed and built. This again allows for pre-assembling and testing. Once there is certainty that all components are functioning properly, the new section can be integrated into the existing belt conveyor.

Both belt trippers and belt plows add function and versatility to a standard troughed belt conveyor, with each piece of equipment offering unique benefits. Whether your process requires material stacking, storing, or removing, FEECO’s custom designed conveyor equipment can provide an innovative solution. Understanding that this additional conveyor equipment is not universal for every process, FEECO can design and fabricate custom solutions that fit your unique handling requirements.