Material handling equipment

Broadly material handling equipment’s can be classified into two categories, namely:

a. Fixed path equipments, and

b. Variable path equipments.

a. Fixed path equipments which move in a fixed path. Conveyors, monorail devices, chutes and pulley drive equipments belong to this category. A slight variation in this category is provided by the overhead crane, which though restricted, can move materials in any manner within a restricted area by virtue of its design. Overhead cranes have a very good range in terms of hauling tonnage and are used for handling bulky raw materials, stacking and at times palletizing

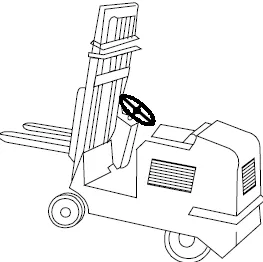

b. Variable path equipments have no restrictions in the direction of movement although their size is a factor to be given due consideration trucks, forklifts mobile cranes and industrial tractors belong to this category. Forklifts are available in many ranges, they are maneuverable and various attachments are provided to increase their versatility.

Material Handing Equipments may be classified in five major categories.

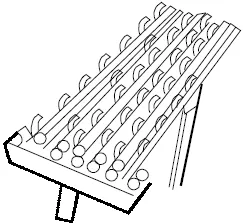

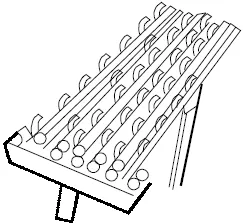

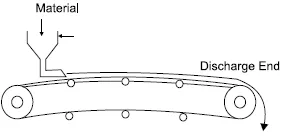

1. CONVEYORS

Conveyors are useful for moving material between two fixed workstations, either continuously or intermittently. They are mainly used for continuous or mass production operations indeed, they are suitable for most operations where the flow is more or less steady. Conveyors may be of various types, with rollers, wheels or belts to help move the material along: these may be power-driven or may roll freely. The decision to provide conveyors must be taken with care, since they are usually costly to install; moreover, they are less flexible and, where two or more converge, it is necessary to coordinate the speeds at which the two conveyors move.

2. INDUSTRIAL TRUCKS

Industrial trucks are more flexible in use than conveyors since they can move between various points and are not permanently fixed in one place. They are, therefore, most suitable for intermittent production and for handling various sizes and shapes of material. There are many types of truck- petrol-driven, electric, hand-powered, and so on. Their greatest advantage lies in the wide range of attachments available; these increase the trucks ability to handle various types and shapes of material.

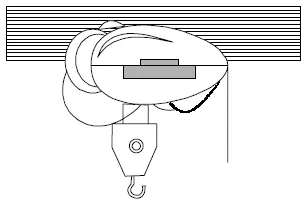

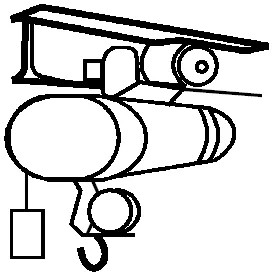

3. CRANES AND HOISTS

The major advantage of cranes and hoists is that they can move heavy materials through overhead space. However, they can usually serve only a limited area. Here again, there are several types of crane and hoist, and within each type there are various loading capacities. Cranes and hoists may be used both for intermittent and for continuous production.

4. CONTAINERS

These are either ‘dead’ containers (e.g. Cartons, barrels, skids, pallets) which hold the material to be transported but do not move themselves, or ‘live’ containers (e.g. wagons, wheelbarrows or computer self-driven containers). Handling equipments of this kind can both contain and move the material, and is usually operated manually.

5. ROBOTS

Many types of robot exist. They vary in size, and in function and maneuverability. While many robots are used for handling and transporting material, others are used to perform operations such as welding or spray painting. An advantage of robots is that they can perform in a hostile environment such as unhealthy conditions or carry on arduous tasks such as the repetitive movement of heavy materials.

The choice of material-handling equipment among the various possibilities that exist is not easy. In several cases the same material may be handled by various types of equipments, and the great diversity of equipment and attachments available does not make the problem any easier. In several cases, however, the nature of the material to be handled narrows the choice. Some of the material handling equipment are shown in the following figures.

Wheel conveyor

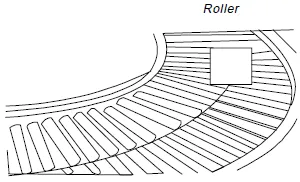

Secrew conveyorRoller

Belt conveyor

Roller conveyor

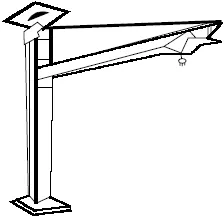

Jib crane

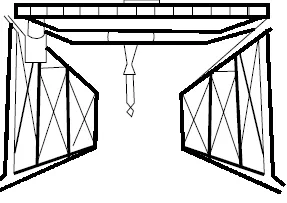

Bridge crane

Platform truck

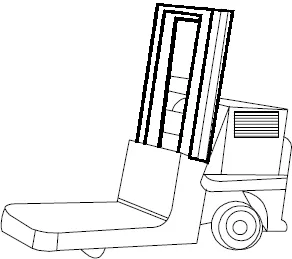

Fork truck

Chain hoist

Electric hoist

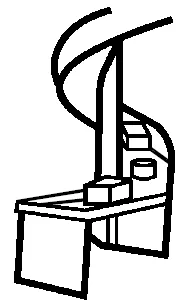

Spiral chute

Industrial tractor

Electrical hoist