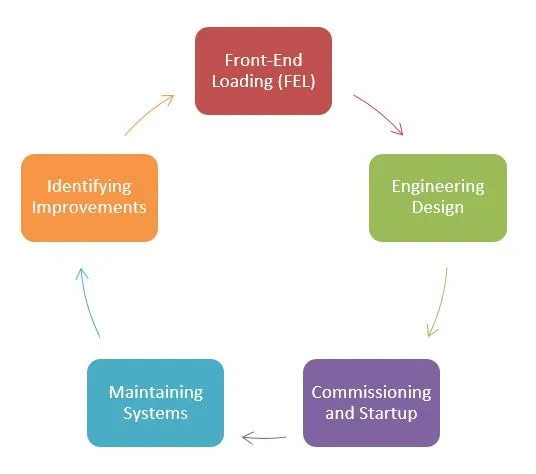

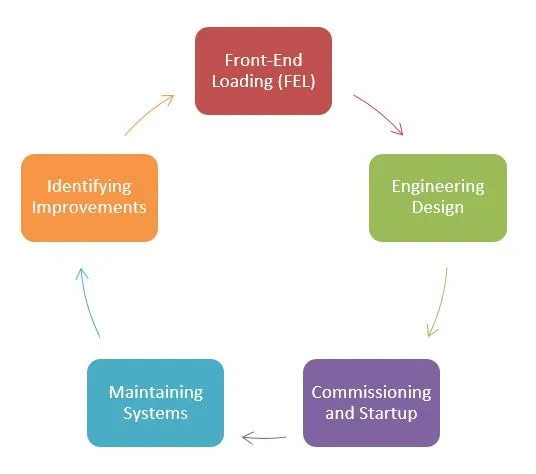

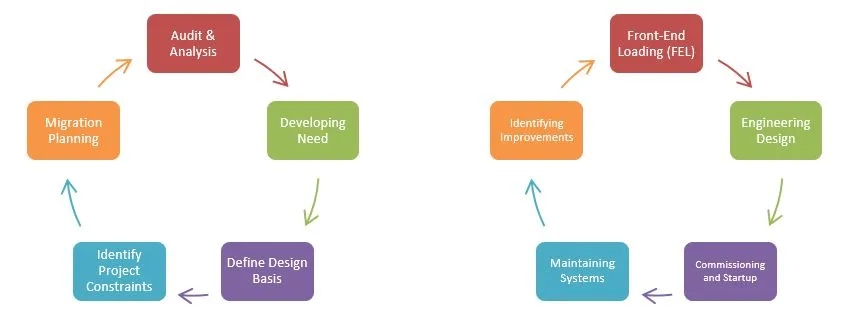

After creating the roadmap during the automation life cycle planning process, the next step in the journey is the design and implementation of the plan. For smaller systems the design and implementation stages of a system upgrade can take weeks or months and not all stages will be visited. For larger systems, design and implementation may take longer and transition over one to five years. These stages may be revisited often prior to completion of the automation changeovers taking place.

Along with the duration of the project, some things to take into consideration may include establishing budgets, migration planning, maintaining systems over time, or using methods such as front-end loading (FEL) to help in planning or future possibilities.

Design and Implementation

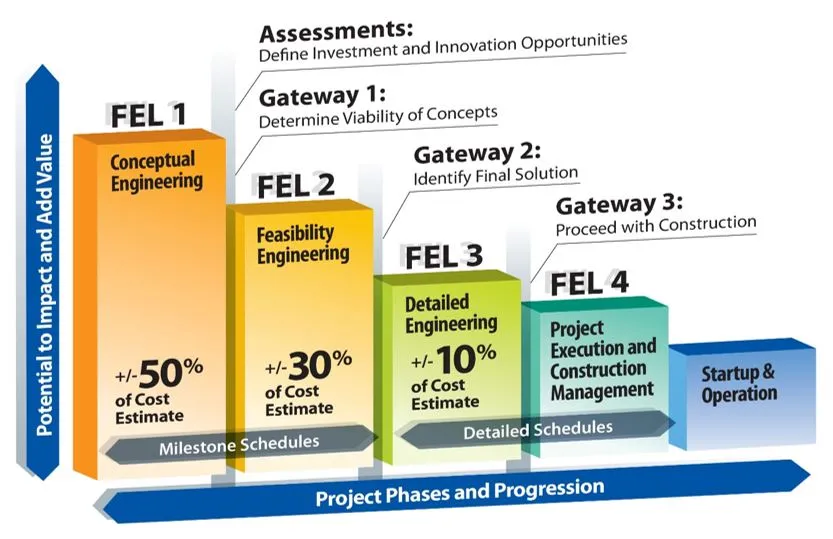

Front-End Loading

Upgrading systems can often uncover unexpected unknowns not identified during planning stages. When selecting a new control system, other process or electrical equipment may need to be upgraded to support full migration. Instrumentation, network hardware, network infrastructure, software and systems infrastructure may need to be looked at as well to support full conversion. Some control systems can last 20 or even 30 years or longer, surpassing the tenure of an employee at any given site. There may not be experienced enough personnel on site to handle looking at all areas needing to be upgraded. Proper front-end loading (FEL) efforts can help determine full project costs including installation estimates. FEL is a method that uses sophisticated capabilities to help determine the project’s viability and feasibility. These methods typically revisit stages of the planning process in efforts to define gateways, where the systems are reviewed as a whole.

Internal project processes determine how far to take initial cost estimates for approval. This could be as elaborate as developing a pilot system to test theories and develop real samples, or as simple as estimating high-level factored costs for implementation. A pre-engineering effort may help at this stage. When a project is relatively complex, there are many factors that must be considered in the overall design and migration to ensure all costs and risks are identified. This initial effort will help avoid missteps and underestimating the true cost of the upgrade. If this effort results in a cost that exceeds the budget, the team can return to the drawing board and consider alternate approaches to reach the end goal.

Example of FEL Process

Engineering Design

Once the planning team is confident in the cost and schedule for the upgrade, the engineering process can begin. This effort typically includes development of new control systems such as hardware design, control panel design, smart motor control center (MCC) configuration, safety systems, industrial networks, and many more. Security of automation software is a key industry trend as the automation world moves into the internet of things. Firewall, virtual private network (VPN), and other security measures, such as separation of information technology (IT) business networks and operational technology (OT) industrial networks, needs to be considered. The International Society of Automation (ISA) 99 structure is a great starting point to develop this approach.

Advanced capabilities for historian software can be leveraged to help reduce downtime in the future. Historian development and report generation are areas that can be touched during the design phase. Working with operations and maintenance during the design process can help ensure a buy-in to the new systems. Software considerations should be made while reviewing, developing, and deploying upgraded systems to deliver results that support the design basis uncovered during the planning process.

A functional specification should be developed for a control system, since it defines the overall operation of the system. Typically, this specification is reviewed and approved by all parties involved prior to full design of the project. The functional specification will help streamline the software development phase, aligns expectations by clearly stating what the system will do, and helps all project members understand the scope of the project.

To ensure a smooth and efficient startup, a factory acceptance test (FAT) should be performed on the completed software system. A FAT typically will use as much of the new automation hardware and software as possible allowing operators, supervisors and other identified plant personnel a chance to test the system prior to going live. A test specification should also be developed to thoroughly test the system and to demonstrate that the system performs in accordance with the functionality described in the functional specification.

Commissioning and Start-Up

New systems need to be thoroughly commissioned and checked out prior to turning over to production. Once the equipment is installed, proper testing of devices, interlocks and equipment is necessary to validate the control system. Safety checks should be performed to ensure that the system will shut down properly in the event of an emergency or planned stop.

Network and security checks also need to be performed in order to ensure site and company information is not publicly available. Involving the IT department in project reviews ensures that the project meets the guidelines and requirements of the company standards for security. For larger projects and larger organizations, getting IT involved early can help save headaches in the completion of projects.

Maintaining Systems

Maintaining systems is an important part of the life cycle. Continual maintenance of both software applications and physical hardware is needed to support the control system over its life at the facility. Developing a spares inventory for current systems can also help reduce downtime in the event of a hardware failure. Ongoing training of both maintenance and operations personnel is required to support the control system. Service contracts with outside companies such as instrumentation specialists, engineering firms, or mechanical and electrical contractors can help offset keeping those experts on staff.

Data collection by a historian can help log information such as equipment run time, faults, maintenance information from smart instruments, personnel who addressed the issue, and many more features. This can help give facilities better information to track down issues and reduce outage time. Plant meters and other devices can be logged to create reports over time. User interface for maintenance modes can be developed to give plant personnel quick access to information commonly gathered such as motor status, valve limit status, alarm status and alarm history.

Identifying Improvements

All of this information feeds into making improvements that help maintain, improve and sustain the facility. Improvements could be something small, such as making the process safer for operators, to something more complex, such as integrating additional capabilities or reconfiguring existing process to make room for future expansions. Each modification adds another chapter of the book that tells the story of the life cycle of the automation. A well-designed plan for upgrades will allow for expansion following the same design basis developed previously. Once the improvements are identified one can begin either the planning process or design and implementation cycles identified in this two-part collection.

Conclusion

Automation life cycle planning is a continuous process that leads to a successful design and implementation phase. Design and implementation is also a continuous process, sometimes spanning several years, during which further improvements to the system are identified. Best automation design practice is not to let life cycle planning end with a completely running system, but rather to continue to plan for further enhancements to the system by making continuous improvements and planning for dealing with eventual obsolete systems.

Matrix Technologies is one of the largest independent process design, industrial automation engineering, and manufacturing operations management companies in North America. To learn more about our manufacturing operations management capabilities and manufacturing process control solutions, contact Tony Ferguson, Associate Department Manager.