Motors and loads

Three phase asynchronous motors

The first part deals with 3-phase asynchronous motors, the one most usually used for driving machines. These motors have a number of advantages that make them the obvious choice for many uses: they are standardised, rugged, easy to operate and maintain and cost-effective.

Operating Principle

The operating principle of an asynchronous motor involves creating an induced current in a conductor when the latter cuts off the lines of force in a magnetic field, hence the name “induction motor”. The combined action of the induced current and the magnetic field exerts a driving force on the motor rotor.

Let’s take a shading ring ABCD in a magnetic field B, rotating round an axis xy.

If, for instance, we turn the magnetic field clockwise, the shading ring undergoes a variable flux and an induced electromotive force is produced which generates an induced current (Faraday’s law).

According to Lenz’s law, the direction of the current is such that its electromagnetic action counters the cause that generated it. Each conductor is therefore subject to a Lorentz force F in the opposite direction to its own movement in relation to the induction field.

An induced current is generated in a short-circuited shading ring

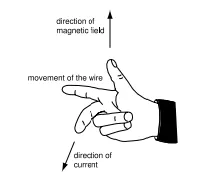

An easy way to define the direction of force F for each conductor is to use the rule of three fingers of the right hand (action of the field on a current.

The thumb is set in the direction of the inductor field. The index gives the direction of the force.

The middle finger is set in the direction of the induced current. The shading ring is therefore subject to a torque which causes it to rotate in the same direction as the inductor field, called a rotating field. The shading ring rotates, and the resulting electromotive torque balances the load torque

Rule of three fingers of the right hand to find the direction of the force

Generating the rotating field

Three windings, offset geometrically by 120, are each powered by one of the phases in a 3-phase AC power supply.

The windings are crossed by AC currents with the same electrical phase shift, each of which produces an alternating sine-wave magnetic field. This field, which always follows the same axis, is at its peak when the current in the winding is at its peak.

Principle of the 3-phase asynchronous motor

The field generated by each winding is the result of two fields rotating in opposite directions, each of which has a constant value of half that of the peak field. At any instant t1 in the period (C Fig. 4), the fields produced by each winding can be represented as follows:

- field H1 decreases. Both fields in it tend to move away from the OH1 axis,

- field H2 increases. Both fields in it tend to move towards the OH2 axis,

- field H3 increases. Both fields in it tend to move towards the OH3 axis.

The flux corresponding to phase 3 is negative. The field therefore moves in the opposite direction to the coil.

Fields generated by the three phases

If we overlay the 3 diagrams, we can see that:

- the three anticlockwise fields are offset by 120° and cancel each other out,

- the three clockwise fields are overlaid and combine to form the rotating field with a constant amplitude of 3Hmax/2. This is a field with one pair of poles,

- this field completes a revolution during a power supply period. Its speed depends on the mains frequency (f) and the number of pairs of poles (p). This is called “synchronous speed”.

Slip

A induced current can only circulate in the shading ring if a flux variation exist in this shading ring. Therefore, there must be a difference in speed in the shading ring and the rotating field.

This is why an electric motor operating to the principle described above is called an “asynchronous motor”. The difference between the synchronous speed (Ns) and the shading ring speed (N) is called “slip” (s) and is expressed as a percentage of the synchronous speed.

s = [(Ns - N) / Ns] x 100.

In operation, the rotor current frequency is obtained by multiplying the power supply frequency by the slip. When the motor is started, the rotor current frequency is at its maximum and equal to that of the stator current. The stator current frequency gradually decreases as the motor gathers speed.

The slip in the steady state varies according to the motor load. Depending on the mains voltage, it will be less if the load is low and will increase if the motor is supplied at a voltage below the rated one.

Synchronous speed

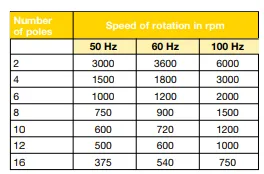

The synchronous speed of 3-phase asynchronous motors is proportional to the power supply frequency and inversely proportional to the number of pairs in the stator. Example: Ns = 60 f/p.

Where:

Ns: synchronous speed in rpm

f: frequency in Hz

p: number of pairs of poles.

The table gives the speeds of the rotating field, or synchronous speeds, depending on the number of poles, for industrial frequencies of 50Hz and 60Hz and a frequency of 100Hz.

Synchronous speeds based on number of poles and current frequency

In practice, it is not always possible to increase the speed of an asynchronous motor by powering it at a frequency higher that it was designed for, even when the voltage is right. Its mechanical and electrical capacities must be ascertained first.

As already mentioned, on account of the slip, the rotation speeds of loaded asynchronous motors are slightly lower than the synchronous speeds given in the table.

Structure

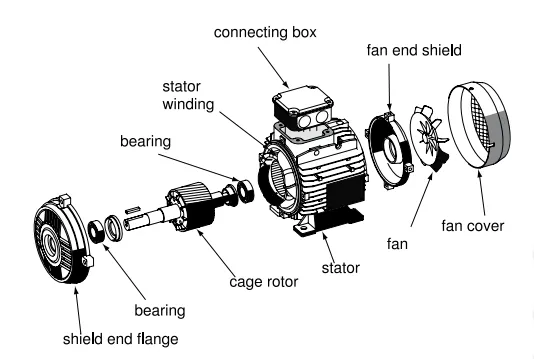

A 3-phase asynchronous squirrel cage motor consists of two main parts: an inductor or stator and an armature or rotor.

Stator

This is the immobile part of the motor. A body in cast iron or a light alloy houses a ring of thin silicon steel plates (around 0.5mm thick). The plates are insulated from each other by oxidation or an insulating varnish. The “lamination” of the magnetic circuit reduces losses by hysteresis and eddy currents.

The plates have notches for the stator windings that will produce the rotating field to fit into (three windings for a 3-phase motor). Each winding is made up of several coils. The way the coils are joined together determines the number of pairs of poles on the motor and hence the speed of rotation

Rotor

This is the mobile part of the motor. Like the magnetic circuit of the stator, it consists of stacked plates insulated from each other and forming a cylinder keyed to the motor shaft.

The technology used for this element divides asynchronous motors into two families: squirrel cage rotor and wound slip ring motors.

Types of rotor

Squirrel cage rotors

There are several types of squirrel cage rotor, all of them designed as shown in figure 6. From the least common to the most common:

Exploded view of a squirrel cage rotor

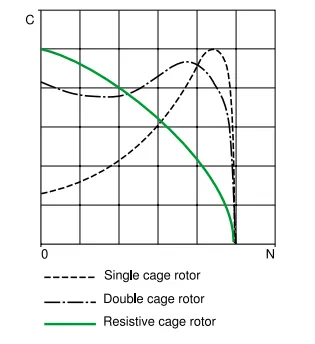

• Resistant rotor

The resistant rotor is mainly found as a single cage (see the definition of single-cage motors below). The cage is closed by two resistant rings (special alloy, reduced section, stainless steel rings, etc.).

These motors have a substantial slip at the rated torque. The starting torque is high and the starting current low.

Their efficiency is low due to losses in the rotor.

These motors are designed for uses requiring a slip to adapt the speed according to the torque, such as:

- several motors mechanically linked to spread the load, such as a rolling mill train or a hoist gantry,

- winders powered by Alquist (see note) motors designed for this purpose,

- uses requiring a high starting torque with a limited current inrush (hoisting tackle or conveyors).

Their speed can be controlled by changing the voltage alone, though this function is being replaced by frequency converters. Most of the motors are self-cooling but some resistant cage motors are motor cooled (drive separate from the fan).

Torque/speed curves of cage rotor types (at nominal voltage)

• Single cage rotor

In the notches or grooves round the rotor (on the outside of the cylinder made up of stacked plates), there are conductors linked at each end by a metal ring. The driving torque generated by the rotating field is exerted on these conductors. For the torque to be regular, the conductors are slightly tilted in relation to the motor axis. The general effect is of a squirrel cage, whence the name.

The squirrel cage is usually entirely moulded (only very large motors have conductors inserted into the notches). The aluminium is pressure-injected and the cooling ribs, cast at the same time, ensure the short-circuiting of the stator conductors.

These motors have a fairly low starting torque and the current absorbed when they are switched on is much higher than the rated current.

On the other hand, they have a low slip at the rated torque. They are mainly used at high power to boost the efficiency of installations with pumps and fans. Used in combination with frequency converters for speed control, they are the perfect solution to problems of starting torque and current.

• Double cage rotor

This has two concentric cages, one outside, of small section and fairly high resistance, and one inside, of high section and lower resistance. - On first starting, the rotor current frequency is high, and the resulting skin effect causes the entire rotor current to circulate round the edge of the rotor and thus in a small section of the conductors. The torque produced by the resistant outer cage is high and the inrush is low

- At the end of starting, the frequency drops in the rotor, making it easier for the flux to cross the inner cage. The motor behaves pretty much as though it were made from a single non-resistant cage. In the steady state, the speed is only slightly less than with a single-cage motor.

• Deep-notch rotor

This is the standard rotor.

Its conductors are moulded into the trapezoid notches with the short side on the outside of the rotor.

It works in a similar way to the double-cage rotor: the strength of the rotor current varies inversely with its frequency.

Thus:

- on first starting, the torque is high and the inrush low,

- in the steady state, the speed is pretty much the same as with a single-cage rotor.

Wound rotor (slip ring rotor)

This has windings in the notches round the edge of the rotor identical to those of the stator.

The rotor is usually 3-phase. One end of each winding is connected to a common point (star connection). The free ends can be connected to a centrifugal coupler or to three insulated copper rings built into the rotor. These rings are rubbed by graphite brushes connected to the starting device.

Depending on the value of the resistors in the rotor circuit, this type of motor can develop a starting torque of up to 2.5 times the rated torque. The starting current is virtually proportional to the torque developed on the motor shaft.

This solution is giving way to electronic systems combined with a standard squirrel cage motor. These make it easier to solve maintenance problems (replacement of worn motor brushes, maintenance of adjustment resistors), reduce power dissipation in the resistors and radically improve the installation’s efficiency

Exploded view of a slip ring rotor motor

Single-phase motors

Squirrel cage single-phase motors

For the same power, these are bulkier than 3-phase motors. Their efficiency and power factor are much lower than a 3-phase motor and vary considerably with the motor size and the manufacturer.

In Europe, the single-phase motor is little used in industry but commonly used in the USA up to about ten kW.

Though not very widely used, a squirrel cage single-phase motor can be powered via a frequency converter, but very few manufacturers offer this kind of product.

Structure

Like the 3-phase motor, the single-phase motor consists of two parts: the stator and the rotor.

• Stator This has an even number of poles and its coils are connected to the mains supply.

• Rotor Usually a squirrel cage.

Operating Principle

Let’s take a stator with two windings connected to the mains supply L1 and N.

The single-phase alternating current generates a single alternating field H in the rotor – a superposition of the fields H1 and H2 with the same value and rotating in opposite directions.

At standstill, the stator being powered, these fields have the same slip in relation to the rotor and hence generate two equal and opposing torques.

The motor cannot start

Operating principle of a single-phase asynchronous motor

A mechanical pulse on the rotor causes unequal slips. One of the torques decreases while the other increases. The resulting torque starts the motor in the direction it was run in.

To overcome this problem at the starting stage, another coil offset by 90° is inserted in the stator. This auxiliary phase is powered by a phase shift device (capacitor or inductor); once the motor has started, the auxiliary phase can be stopped by a centrifugal contact.

Another solution involves the use of short circuit phase-shift rings, built in the stator which make the field slip and allow the motor to start. This kind of motor is only found in low-power devices (no more than 100W

Single phase short circuit phase-shift rings

Synchronous motors

Universal single-phase motors

Though little used in industry, this is most widely-made motor in the world. It is used in domestic appliances and portable tools.

Its structure is similar to that of a series wound direct current motor. As the unit is powered by alternating current, the flux in the machine is inverted at the same time as the voltage, so the torque is always in the same direction. It has a wound stator and a rotor with windings connected to rings. It is switched by brushes and a collector. It powers up to 1000W and its no-load rotation speed is around 10,000 rpm. These motors are designed for inside use. Their efficiency is rather poor.

Universal single-phase motor

Magnetic rotor synchronous motors

Structure

Like the asynchronous motor, the synchronous motor consists of a stator and a rotor separated by an air gap. It is different in that the flux in the air gap is not due to an element in the stator current but is created by permanent magnets or by the inductor current from an outside source of direct current powering a winding in the rotor.

• Stator

The stator consists of a body and a magnetic circuit usually made of silicon steel plates and a 3-phase coil, similar to that of an asynchronous motor, powered by a 3-phase alternating current to produce a rotating field.

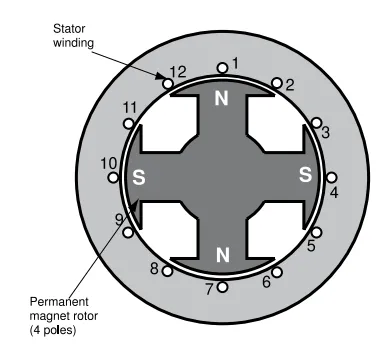

• Rotor

The rotor has permanent magnets or magnetising coils through which runs a direct current creating intercalated north-south poles. Unlike asynchronous machines, the rotor spins at the speed of the rotating field with no slip.

There are thus two distinct types of synchronous motor: magnetic motors and coil rotor motors.

- In the former, the rotor is fitted with permanent magnets , usually in rare earth to produce a high field in a small space. The stator has 3-phase windings. These motors support high overload currents for quick acceleration. They are always fitted with a speed controller. Motor-speed controller units are designed for specific markets such as robots or machine tools where smaller motors, acceleration and bandwidth are mandatory.

Cross section of a 4-pole permanent magnet motor

- The other synchronous machines have a wound rotor. The rotor is connected rings although other arrangements can be found as rotating diodes for example. These machines are reversible and can work as generators (alternators) or motors. For a long while, they were mainly used as alternators – as motors they were practically only ever used when it was necessary to drive loads at a set speed in spite of the fairly high variations in their load torque.

The development of direct frequency converters (of cycloconverter type) or indirect converters switching naturally due to the ability of synchronous machines to provide reactive power has made it possible to produce variable-speed electrical drives that are powerful, reliable and very competitive compared to rival solutions when power exceeds one megawatt.

Synchronous wound rotor motor

Though industry does sometimes use asynchronous motors in the 150kW to 5MW power range, it is at over 5MW that electrical drives using synchronous motors have found their place, mostly in combination with speed controllers.

Operating Characteristics

The driving torque of a synchronous machine is proportional to the voltage at its terminals whereas that of an asynchronous machine is proportional to the square of the voltage.

Unlike an asynchronous motor, it can work with a power factor equal to the unit or very close to it.

Compared to an asynchronous motor, a synchronous one has a number of advantages with regard to its powering by a mains supply with constant voltage and frequency:

- the motor speed is constant, whatever the load,

- it can provide reactive power and help improve the power factor of an installation,

- it can support fairly big drops in voltage (around 50%) without stalling due to its overexcitation capacity.

However, a synchronous motor powered directly by a mains supply with constant voltage and frequency does have two disadvantages:

- it is difficult to start; if it has no speed controller, it has to be no-load started, either directly for small motors or by a starting motor which drives it at a nearly synchronous speed before switching to direct mains supply,

- it can stall if the load torque exceeds its maximum electromagnetic torque and, when it does, the entire starting process must be run again.

Other types of synchronous motors

To conclude this overview of industrial motors, we can mention linear motors, synchronised asynchronous motors and stepper motors.

Linear Motors

Their structure is the same as that of rotary synchronous motors: they consist of a stator (plate) and a rotor (forcer) developed in line. In general, the plate moves on a slide along the forcer.

As this type of motor dispenses with any kind of intermediate kinematics to transform movement, there is no play or mechanical wear in this drive

Synchronised asynchronous motors

These are induction motors. At the starting stage, the motor works in asynchronous mode and changes to synchronous mode when it is almost at synchronous speed.

If the mechanical load is too great, it can no longer run in synchronous mode and switches back to asynchronous mode. This feature is the result of a specific rotor structure and is usually for low-power motors

Stepper motors

The stepper motor runs according to the electrical pulses that power its coils. Depending on the electricity supply, it can be:

- unipolar if the coils are always powered in the same direction by a single voltage;

- bipolar if the coils are powered first in one direction then in the other. They create alternating north and south poles.

Stepper motors can be variable reluctance, magnetic or both.

The minimum angle of rotation between two electrical pulse changes is called a step. A motor is characterised by the number of steps per revolution (i.e. 360°). The common values are 48, 100 or 200 steps per revolution.

Type of stepper motors