Conveyors and revolving tables

This kind of unit is very common in the manufacturing industry. The type of machine greatly depends on the surroundings. Its output has to be adjusted to the product and it is controlled by upstream and downstream automation. One automated device will control several sections in a conveyor and each element will have one or more panels. The main features are:

- low power installation,

- medium performance requirements,

- per section, 2 to 10 three-phase AC motors with AC drives,

- 10 to 50 inputs/outputs,

- interface by keyboard and display,

- real-time knowledge of the type and number of products conveyed.

Since there are several linked equipment’s, the choice should focus on a distributed architecture.

Revolving table

Conveyor

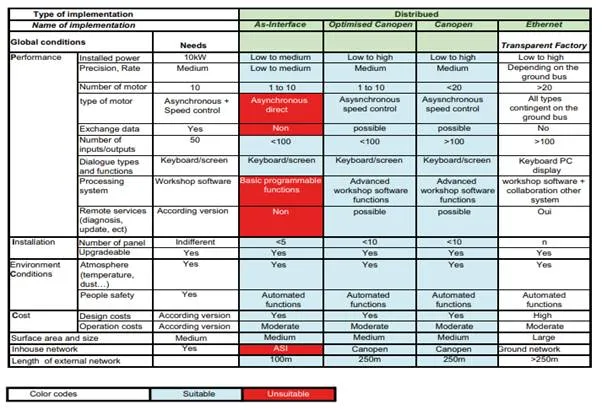

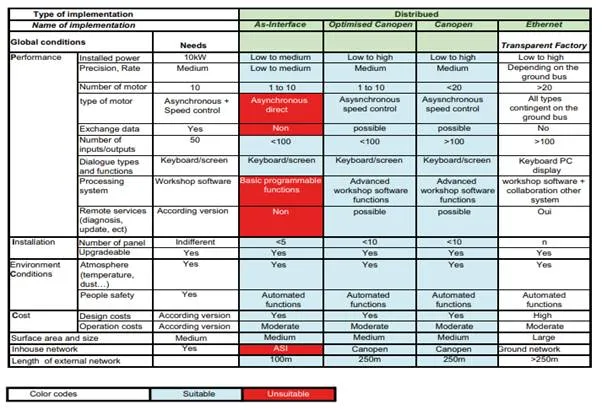

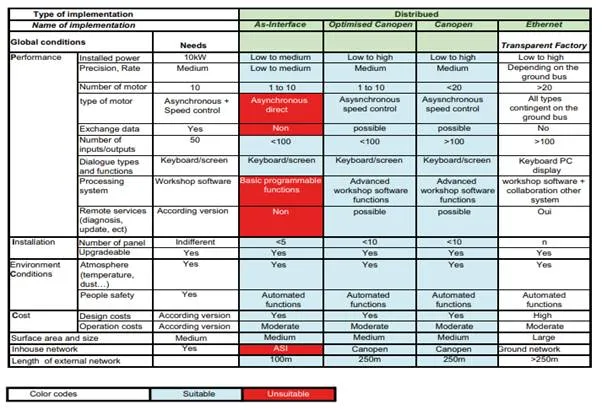

The selection table highlights the best solutions . The ASI bus one is a bit restricted because of the difficulties in speed control and the Ethernet one, except in some specific cases, is likely to be too expensive.

Co

Conveying system choice

This leaves the two CANopen field bus solutions. The first, which is more economical ensures the basic requisite functions and the second ensures transparency and synchronisation with automated devices outside the section involved. It is also easy to upgrade: a new configuration can be downloaded whenever a series is changed and so forth.