Automation architectures

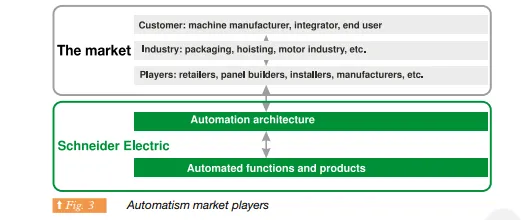

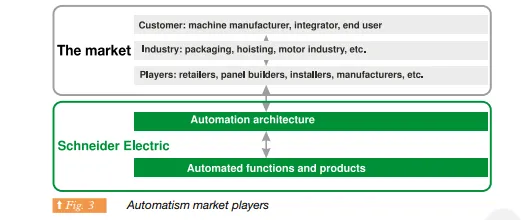

To meet these requirements, an offer for reliable and powerful products must include “ready-to-use” architectures enabling intermediate players such as systems integrators and OEMs to specify and build the perfect solution for any end user. The figure 3 illustrates the relationship between market players and Schneider Electric offer

Architectures add value to the intermediate players, starting with the retailer or wholesaler, panel builder, machine installer or manufacturer. It is a global approach that enables them to respond more reliably, exactly and faster to end customers in different industries such as food, infrastructure or building.

In the late 1990s, the conventional prioritised approach both in manufacturing processes (CIM: Computer Integrated Manufacturing) and in continuous processes (PWS: Plant Wide Systems) gave way to a decentralised approach. Automated functions were implemented as close as possible to the process (see the definition of these terms in the software section.)

The development of web processes based on Ethernet and the TCP/IP protocol began to penetrate complex automated systems. These gradually split up and were integrated into other functions, thus giving rise to «smart devices».

This architecture made it possible to have transparent interconnection between the control systems and IT management tools (MES, ERP).

At the same time, the components (actuators, speed controllers, sensors, input/output devices, etc.) gradually evolved into «smart devices» by integrating programming and communication features.

Smart devices

These include Nano-automated devices, automated cells (such as Power Logic, Sepam, Dial pact, etc.) and components with a regulating function, such as speed controllers. These products are smart enough to manage process functions locally and to interact with each other. Transparent communication means that tasks can be reconfigured, and diagnoses made – these possibilities are perfectly in line with the web process (individual addressing, information formatted to be ready to use, information provider management). The product line of smart devices products is systematically plug and play for power controllers, control bus and sensors. This approach means equipment can be replaced quickly and easily in the event of failure.

The integration of browsers into keyboard and screen systems, radio controls and other MMIs has accelerated deployment of web technologies right up to the component level

The integration of control functions into «smart devices» has reduced the data flow on networks, thereby lowering costs, reducing the power of the automated devices and speeding up response times. There is less need for synchronisation because the smart devices process locally.

Networks

At the same time, networks have been widely accepted and have converged on a limited number of standards which cover 80% of applications. There are many options open to designers (CANopen, AS-Interface, Profibus, DeviceNet, etc.) but the trend is towards a standard single network. In this framework, Ethernet, which has already won over the industrial computerisation sector, can also address needs for ground buses.

A great many elements are now directly network-connectable. This is the result of the combined effects of web-technology distribution, rationalisation of communication standards, the sharp drop in the price of information technology and the integration of electronics into electro-mechanical components.

These developments have led to the definition of field buses adapted to communication between components and automated devices such as Modbus, CANopen, AS-Interface, Device Net, Interbus S, Profibus, Fip, etc.

The increasing need for exchange prompts customers to give priority to the choice of network ahead of automated equipment.

Software and development tools

Programming tools have greatly expanded, from software dependent on hardware platforms to purely functional software downloaded onto a variety of hardware configurations. Communication between components is generated automatically. The information the programs produce is accessed by a unifying tool and shares a common distributed database, which considerably cuts down on the time taken to capture information (parameters, variables, etc.).

So far, industrial automated device programming language concepts have not changed, with practically all suppliers promoting offers based on the IEC 61131-3 standard, sometimes enhanced by tools supporting collaborative control.

Future improvements mainly concern the information generated by products designed to:

- automatically generate the automated device configuration and input/ output naming, - import and export functions to and from the automated device’s software and the components’ software,

- integrate electrical diagrams into diagnostics tools,

- generate a common database, even for a simple configuration,

- offer total transparency,

- offer a single ergonomics which can be learnt once and for all for several uses.

Software is an obligatory ingredient of widely different products and is used not only for programming, but also for configuration, parameter setting and diagnosis. These separate features can be included in the same program