Introduction to Industrial Automation and Control

Lesson Objectives

• To define Automation and Control and explain the differences in the sense of the terms

• To explain the relation between Automation and Information Technology

• To underline the basic objectives of a manufacturing industry and explain how automation and control technologies relate to these

• To introduce the concept of a Product Life Cycle and explain how Automation and Control technologies relate to the various phases of the cycle

• To classify Manufacturing plants and categorise the different classes of Automation Systems that are appropriate for these

Understanding the Title of the Course

Let us first define the three key words in the title, namely,

Industry

In a general sense the term “Industry” is defined as follows.

Definition: Systematic Economic Activity that could be related to Manufacture/Service/ Trade.

In this course, we shall be concerned with Manufacturing Industries only.

Automation

The word ‘Automation’ is derived from Greek words “Auto”(self) and “Matos” (moving). Automation therefore is the mechanism for systems that “move by itself”. However, apart from this original sense of the word, automated systems also achieve significantly superior performance than what is possible with manual systems, in terms of power, precision and speed of operation.

Definition: Automation is a set of technologies that results in operation of machines and systems without significant human intervention and achieves performance superior to manual operation

A Definition from Encyclopaedia Britannica

The application of machines to tasks once performed by human beings or, increasingly, to tasks that would otherwise be impossible. Although the term mechanization is often used to refer to the simple replacement of human labour by machines, automation generally implies the integration of machines into a self-governing system.

Point to Ponder: 1

A. Why does an automated system achieve superior performance compared to a manual one?

B. Can you give an example where this happens?

Control

It is perhaps correct to expect that the learner for this course has already been exposed to a course on Control Systems, which is typically introduced in the final or pre-final year of an undergraduate course in Engineering in India. The word control is therefore expected to be familiar and defined as under.

Definition: Control is a set of technologies that achieves desired patterns of variations of operational parameters and sequences for machines and systems by providing the input signals necessary

Point to Ponder: 2

A. Can you explain the above definition in the context of a common control system, such as temperature control in an oven?

B. Is the definition applicable to open-loop as well as closed loop control?

It is important at this stage to understand some of the differences in the senses that these two terms are generally interpreted in technical contexts and specifically in this course. These are given below.

1. Automation Systems may include Control Systems, but the reverse is not true. Control Systems may be parts of Automation Systems.

2. The main function of control systems is to ensure that outputs follow the set points. However, Automation Systems may have much more functionality, such as computing set points for control systems, monitoring system performance, plant start-up or shutdown, job and equipment scheduling etc.

Automation Systems are essential for most modern industries. It is therefore important to understand why they are so, before we study these in detail in this course.

Point to Ponder: 3

A. Can you give an example of an automated system, which contains a control system as a part of it?

B. What are the other parts of the system?

Industrial Automation vs. Industrial Information Technology

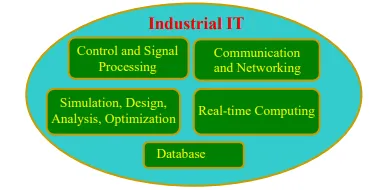

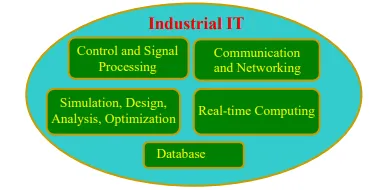

Industrial Automation makes extensive use of Information Technology. Fig. 1.1 below shows some of the major IT areas that are used in the context of Industrial Automation.

Fig. 1.1 Major areas of IT which are used in the context of Industrial Automation.

Point to Ponder: 4

A. Try to find an example automated system which uses at least one of the areas of Industrial IT mentioned in (Hint: Try using the internet)

However, Industrial Automation is distinct from IT in the following senses

B. Industrial Automation also involves significant amount of hardware technologies, related to Instrumentation and Sensing, Actuation and Drives, Electronics for Signal Conditioning, Communication and Display, Embedded as well as Stand-alone Computing Systems etc.

C. As Industrial Automation systems grow more sophisticated in terms of the knowledge and algorithms they use, as they encompass larger areas of operation comprising several units or the whole of a factory, or even several of them, and as they integrate manufacturing with other areas of business, such as, sales and customer care, finance and the entire supply chain of the business, the usage of IT increases dramatically. However, the lower level Automation Systems that only deal with individual or, at best, a group of machines, make less use of IT and more of hardware, electronics and embedded computing.

Point to Ponder: 5

A. Can you give an example of an automated system, some of whose parts makes a significant application of Industrial IT?

B. Can you give an example of an automated system, none of whose parts makes a significant application of Industrial IT?

Apart from the above, there are some other distinguishing features of IT for the factory that differentiate it with its more ubiquitous counterparts that are used in offices and other business.

A. Industrial information systems are generally reactive in the sense that they receive stimuli from their universe of discourse and in turn produce responses that stimulate its environment. Naturally, a crucial component of an industrial information system is its interface to the world.

B. Most of industrial information systems have to be real-time. By that we mean that the computation not only has to be correct, but also must be produced in time. An accurate result, which is not timely may be less preferable than a less accurate result produced in time. Therefore, systems have to be designed with explicit considerations of meeting computing time deadlines.

C. Many industrial information systems are considered mission-critical, in the sense that the malfunctioning can bring about catastrophic consequences in terms of loss of human life or property. Therefore, extraordinary care must be exercised during their design to make them flawless. In spite of that, elaborate mechanisms are often deployed to ensure that any unforeseen circumstances can also be handled in a predictable manner. Fault-tolerance to emergencies due to hardware and software faults must often be built in.

Point to Ponder: 6

A. Can you give an example of an automated system, which is reactive in the sense mentioned above?

B. Can you give an example of an automated system, which is real-time in the sense mentioned above

C. Can you give an example of an automated system, which is mission-critical in the sense mentioned above

Role of automation in industry

· Manufacturing processes, basically, produce finished product from raw/unfinished material using energy, manpower and equipment and infrastructure?

· Since an industry is essentially a “systematic economic activity”, the fundamental objective of any industry is to make profit.

· Roughly speaking,

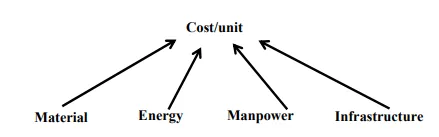

Profit = (Price/unit – Cost/unit) x Production Volume

(1) So profit can be maximised by producing good quality products, which may sell at higher price, in larger volumes with less production cost and time. Shows the major parameters that affect the cost/unit of a mass-manufactured industrial product.

The Components of per unit Manufacturing Cost

Automation can achieve all these in the following ways,

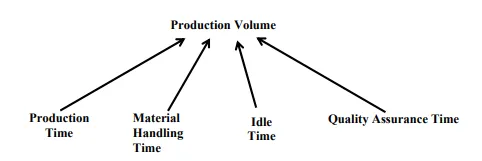

Figure shows how overall production time for a product is affected by various factors. Automation affects all of these factors. Firstly, automated machines have significantly lower production times. For example, in machine tools, manufacturing a variety of parts, significant setup times are needed for setting the operational configuration and parameters whenever a new part is loaded into the machine. This can lead to significant unproductive for expensive machines when a variety of products is manufactured. In Computer Numerically Controlled (CNC) Machining Centers set up time is reduced significantly with the help of Automated Tool Changers, Automatic Control of Machines from a Part Program loaded in the machine computer. Such a machine is shown in Figure 1.3. The consequent increase in actual metal cutting time results in reduced capital cost and an increased volume of production.

Point to Ponder: 7

A. With reference to Eq. (1), explain how the following automation systems improve industrial profitability.

a. Automated Welding Robots for Cars

b. Automated PCB Assembly Machines

c. Distributed Control Systems for Petroleum Refineries

A CNC Machine with an Automated Tool Changer and the Operator Console with Display for Programming and Control of the Machine

The major factors that contribute to Overall Production Time

· Similarly, systems such as Automated Guided Vehicles, Industrial Robots, Automated Crane and Conveyor Systems reduce material handling time.

· Automation also reduces cost of production significantly by efficient usage of energy, manpower and material.

· The product quality that can be achieved with automated precision machines and processes cannot be achieved with manual operations. Moreover, since operation is automated, the same quality would be achieved for thousands of parts with little variation.

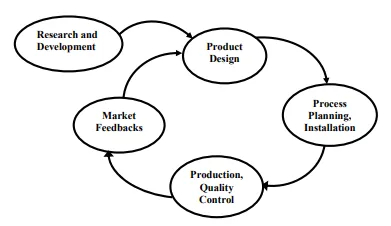

· Industrial Products go through their life cycles, which consists of various stages.

· At first, a product is conceived based on Market feedbacks, as well as Research and Development Activities.

· Once conceived the product is designed. Prototype Manufacturing is generally needed to prove the design.

· Once the design is proved, Production Planning and Installation must be carried out to ensure that the necessary resources and strategies for mass manufacturing are in place.

· This is followed by the actual manufacture and quality control activities through which the product is mass-produced.

· This is followed by a number of commercial activities through which the product is actually sold in the market.

Automation also reduces the overall product life cycle i.e., the time required to complete

(i) Product conception and design

(ii) Process planning and installation

(iii) Various stages of the product life cycle are shown as in Figure

A Typical Industrial Product Life Cycle