Other speed control systems

Variable voltage regulator

This device is only used in low-powered asynchronous motors. It requires a resistant squirrel cage motor.

The speed is controlled by increasing the motor slip once the voltage drops.

Its use was fairly widespread in cooling systems, pumps and compressors, uses for which its torque availability gives satisfactory results. It is gradually giving way to more cost-effective frequency converters.

Other electromechanical systems

The other electromechanical speed control systems mentioned below are less used now that electronic speed controllers are in common use.

• AC squirrel cage motors (Schrage) These are special motors where the speed is controlled by varying the position of the brushes on the collector in relation to the neutral.

• Eddy current drives This consists of a drum connected directly to an asynchronous motor running at constant speed and a rotor with a coil feeded with direct current .

Cross section of an eddy current drive

Electric motor comparison

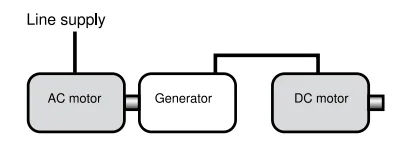

• Ward Leonard motor generator set

This device, once very widespread, is the forerunner of DC motor speed controllers. It has a motor and a DC generator which feeds a DC motor.

The speed is controlled by regulating the excitation of the generator. A very small current is used to control powers of several hundred kW in all the torque and speed quadrants. This type of controller was used in rolling mills and pithead lifts.

This was the most efficient speed control system before it was made obsolete by the semiconductor

Ward Leonard arrangement

Mechanical and hydraulic speed controllers

Mechanical and hydraulic speed controllers are still in use. Many mechanical speed control systems have been designed (pulleys/ belts, bearings, cones, etc.). The drawbacks of these controllers are that they require careful maintenance and do not lend themselves easily to servo control. They are now seriously rivalled by frequency converters. Hydraulic speed controllers are still widely used for specific purposes. They have substantial power weight ratios and a capacity to develop continuous high torques at zero speed. In industry, they are mostly used in power-assisted systems. As this type of speed controller is not relevant to this guide, we shall not describe it in detail.

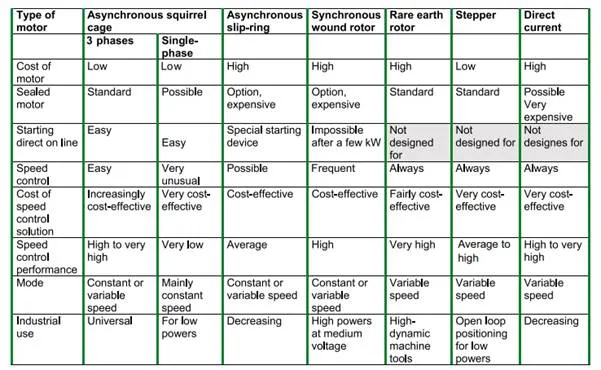

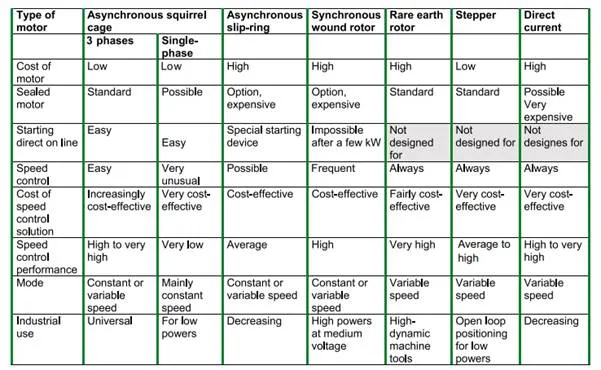

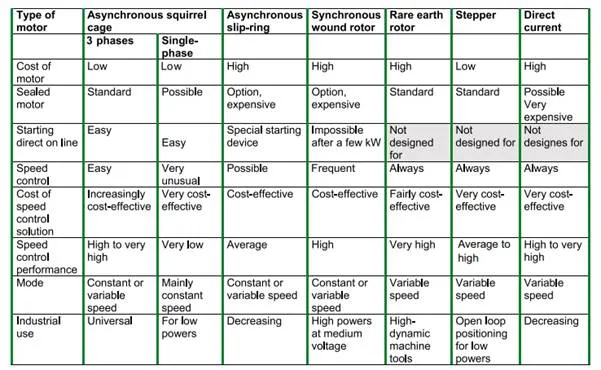

The table gives a brief summary of all the types of electric motor available, their main feature and fields of use. We should point out the place held by 3-phase squirrel cage motors where the description “standard” is all the more relevant since the development of electronic speed control devices has fitted them perfectly to fit closely

to the application.

We can classify the loads in two families: - the active loads which put moving a mobile or a fluid or which change its state like the gas state in the liquid state, - the passive loads which do not get a driving force like lighting or the heating

Active loads

This term covers all systems designed to set a mobile object or a fluid in motion. The movement of a mobile object involves changing its speed or position, which implies applying a torque to overcome its resistance to movement so as to accelerate the inertia of the load. The speed of movement is directly related to on the torque applied.

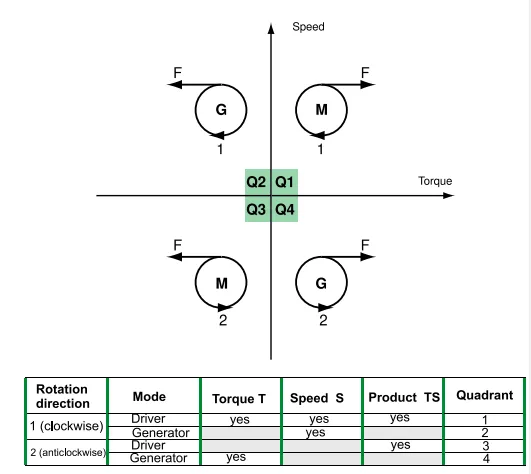

Operating quadrants

The figure illustrates the four possible situations in the torque-speed diagram of a machine.

Note that when a machine works as a generator it must have a driving force. This state is used in particular for braking. The kinetic energy in the shaft is either transferred to the power system or dissipated in a resistor or, for low power, in machine losses.

The four possible situations for a machine in a torque-speed diagram