WHAT IS THE DIFFERENCE BETWEEN SCADA AND HMI?

Today, you will learn the difference between SCADA and HMI. We will talk about the differences as well as the similarities, and also when each is used. There is usually some confusion because of the similarities.

So let’s dive in to SCADA for now. SCADA stands for “Supervisory Control and Data Acquisition.”

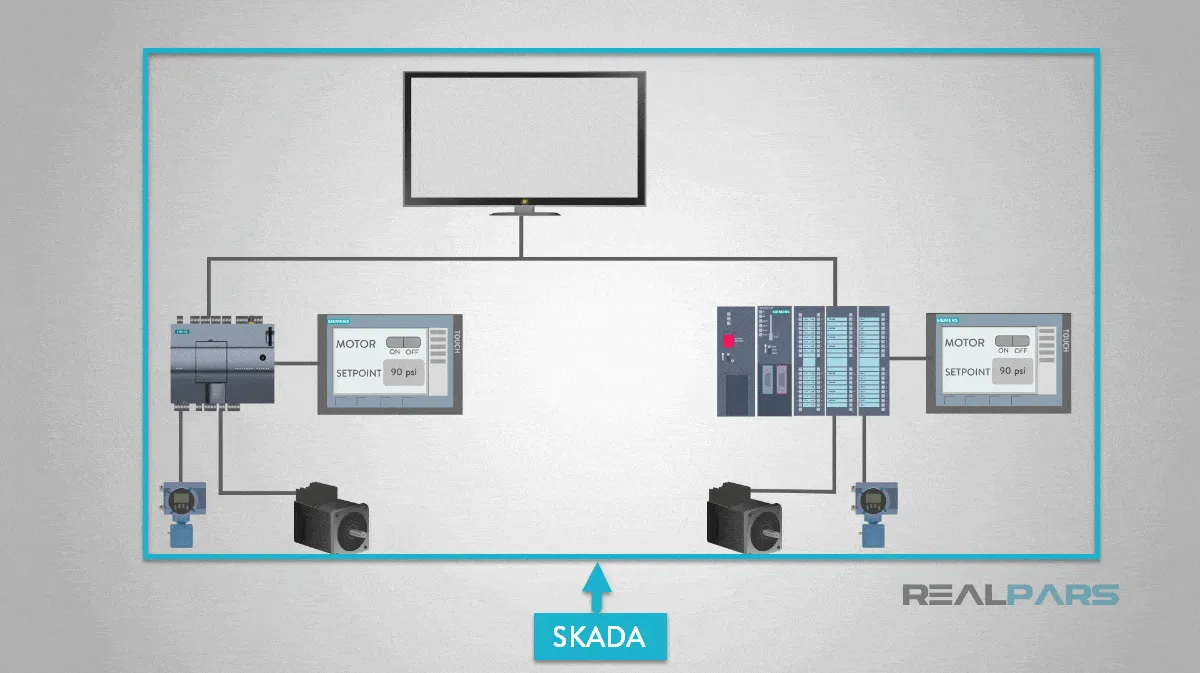

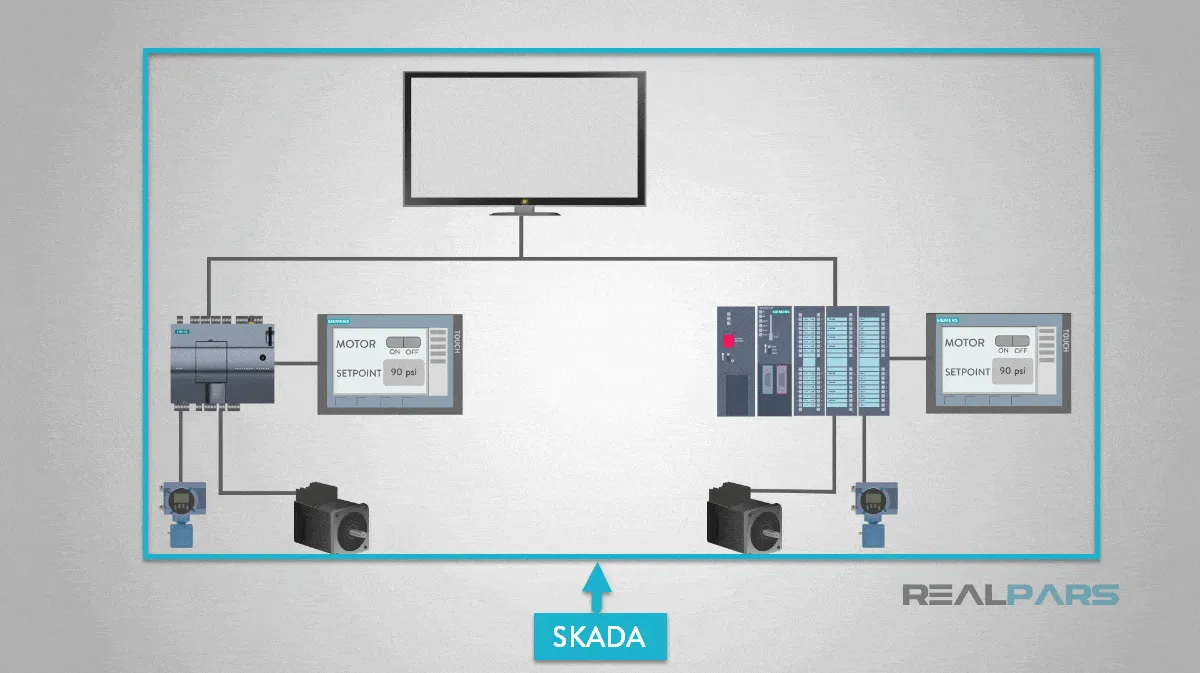

These are used for monitoring and controlling large areas, typically a full site or plant. SCADA systems are a combination of many systems including sensors, RTUs or Remote Terminal Units, and PLCs. Data from all of these systems is then sent to the central SCADA unit. That SCADA unit has its own HMI. This is why a lot of people get confused and think SCADA and HMI are one and the same. That HMI or “Human Machine Interface” unit on the SCADA can monitor and control anything that is connected to it. In conclusion, HMI can be part of SCADA but SCADA cannot be part of a HMI. It’s that simple.

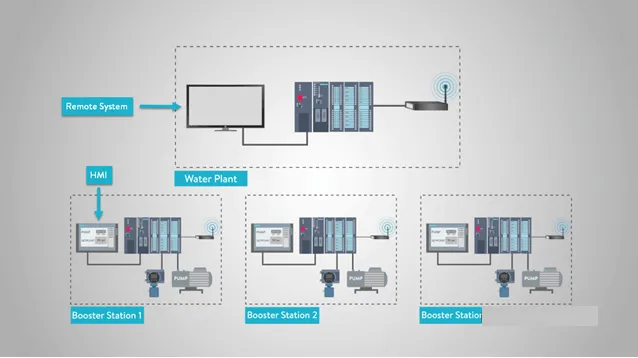

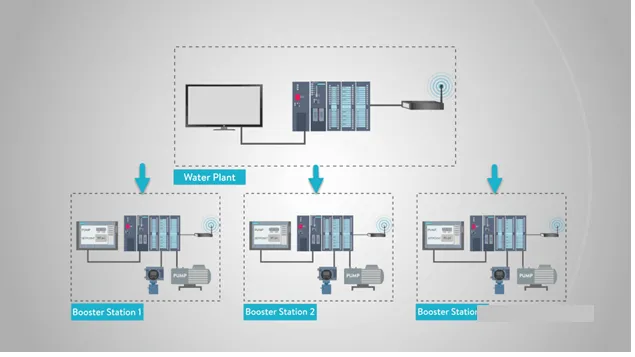

So let’s talk about a common use for SCADA that I have personally encountered. While working for a water and wastewater treatment facility I encountered a SCADA system. The HMI was located at the main water plant building. This HMI was connected to the main SCADA unit at the water plant.

Each booster pump station within the water district was represented on the screen.

At each location there was a PLC that was connected to some sensors to monitor water flow, pressure, and other things, and it was able to run and control the pump itself.

The remote SCADA unit was connected to the PLC system and allowed operators to control and monitor each pump station from the main plant. I’m sure you can imagine how much time and labor a good SCADA system can save a company.

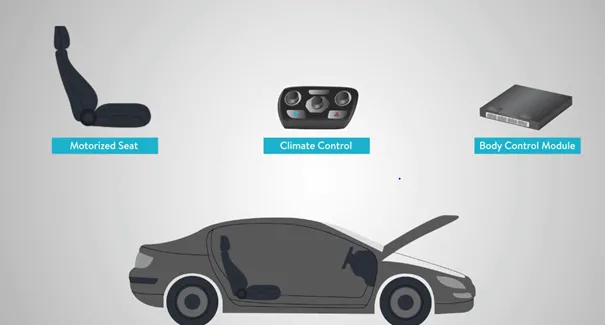

I like to think of a SCADA system kind of like a modern vehicle. You have several different sensors connected to different computers on board. Most of your interior features like motorized seats, climate control and other things are controlled by a BCM or body control module.

Most of your engine functions and sensors are monitored and controlled by your ECM or engine control module.

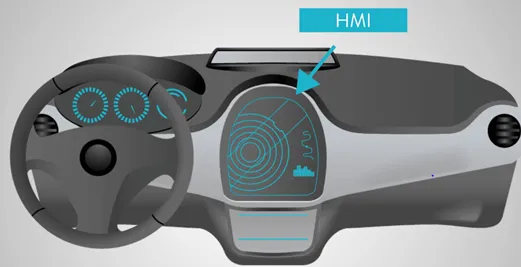

These modules all send information to a main screen in your dash for you to see and control through driver controls which is essentially your HMI.

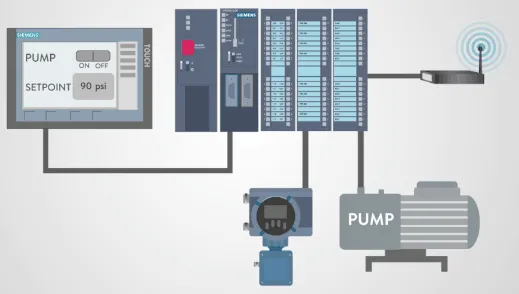

An HMI is essentially a user control station, usually in the form of a touchscreen or a screen with some buttons attached. They are typically tied to a machine or process.

Most HMI applications have the screen tied to a PLC that it is compatible with. Certain functions and sensors can be programmed to monitor and control on the screen itself. Be sure to check out our RealPars blog post on HMIs.

So what did we learn today? Hopefully you now know the difference between a SCADA and HMI. They are different but can be used together to create a very functional and useful industrial tool. A SCADA system is comprised of remote systems all tied together at one central hub.

Our example was the water treatment pumps that were located all over a water district. They were able to be controlled and monitored from a central location at the water plant. An HMI is an interface for humans to monitor and control a machine. Even our SCADA systems will typically involve an HMI. HMIs are usually connected to one machine or process and are able to monitor and control certain functions of that machine or process.