What is a material-handling system?

· A material-handling system can be simply defined as an integrated system involving such activities as handling, storing, and controlling of materials.

· The word material has very broad meaning, covering all kinds of raw materials, work in process, subassemblies, and finished assemblies.

· The primary objective of using a material handling system is to ensure that the material in the right amount is safely delivered to the desired destination at the right time and at minimum cost.

· The material handling system is properly designed not only to ensure the minimum cost and compatibility with other manufacturing equipment but also to meet safety concerns.

Principles of Material Handling

20 basic guidelines for designing and operating material-handling systems.

1. Orientation principle: study the system relationships thoroughly prior to preliminary planning in order to identify existing methods and problems, physical and economic constraints, and to establish future requirements and goals.

2. Planning principle: establish a plan to include basic requirements, desirable options, and consideration of contingencies for all MH and storage activities.

3. System principle: integrate the handling and storage activities that are economically viable into a coordinated system of operation including receiving, inspection, storage, production, assembly, packaging, warehousing, shipping, and transportation.

4. Unit load principle: handle product in as large a unit load as practical.

5. Space utilization principle

6. Standardization principle

7. Ergonomic principle: recognize human capabilities and limitations

8. Energy principle

9. Ecology principle: minimize adverse effects on the environment when selecting MH equipment ad procedures.

10.Mechanization principle: mechanize the handling process where feasible to increase efficiency and economy in handling of materials.

11.Flexibility principle: use methods and equipment that can perform a variety of tasks under a variety of operating conditions.

12.Simplification principle: simplify handling by eliminating, reducing, or combining unnecessary movements and/or equipment.

13.Gravity principle

14.Safety principle

15.Computerization principle: improved material and information control.

16.System flow principle: integrate data flow with the physical material flow in handling and storage.

17.Layout principle

18.Cost principle

19.Maintenance principle

20.Obsolescence principle

Material Handling Equipment

· Industrial trucks include hand trucks such as two-wheeled, four-wheeled, hand lift, and forklift and powered trucks such as forklift, tractor-trailer trains, industrial crane trucks, and side loaders.

· Conveyors such as belt, chute, roller, wheel, slat, chain, bucket, trolley, tow, screw, vibrating, and pneumatic.

· Monorails, hoists, and cranes such as bridge, gantry, tower, and stacker.

· Automated guided vehicle systems such as unit load carriers, towing, pallet trucks, fork trucks, and assembly line.

· Automated storage and retrieval systems (AS/RS) such as unit load, mini-load, person-on-board, deep lane, and storage carousel systems.

Automated guided vehicle systems

· An automated guided vehicle system is a battery-powered driver-less vehicle with programming capabilities for destination, path selection, and positioning.l

· The AGVS belongs to a class of highly flexible, intelligent, and versatile material handling systems used to transport materials from various loading locations to various unloading locations throughout the facility.

· The components of an AGVS

1. The vehicle. It is used to move the material within the system without a human operator.

2. The guide path. It guides the vehicle to move along the path.

3. The control unit. It monitors and directs system operations including feedback on moves, inventory, and vehicle status.

4. The computer interface. It interfaces with other computers and systems such as the mainframe host computer, the automated storage and retrieval system, and the flexible manufacturing system.

The type of AGVSs

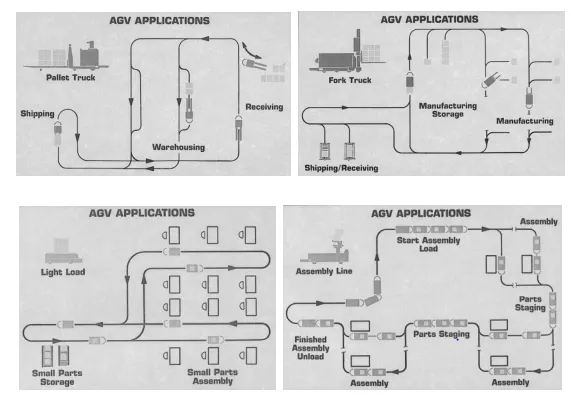

1. AGVS towing vehicles: usually, towing applications involve the bulk movement of product into and out of warehouse areas. Towing vehicles are better used for large volumes with long moving distances of 1000 ft or more.

2. AGVS unit load transporters: are equipped with decks that permit transportation of an individual unit load on board the vehicle. The deck can be powered or non-powered roller, chain or belt deck, lift-and-lower type, or custom deck with multiple compartments. Unit load transporters are often equipped with automatic load transfer and normally used in warehousing and distribution systems where the guide path lengths are relatively short but the volumes are high.

3. AGVS pallet trucks: are designed to lift, maneuver, and transport palletized loads. The vehicle is used for picking up and dropping off loads from and to floor level, thus eliminating the need for fixed load stands. It can be loaded and unloaded in automatically or manually. For load transportation, the vehicle normally proceeds along the path to a specific storage area destination, pulls off onto a spur, lowers the pallet forks to the floor, pulls from the pallet, and then automatically returns empty to the loading area.

4. AGVS forklift trucks: has the ability to pick up and drop off palletized loads both at floor level and on stands, and pickup height can be different from the drop-off height. The vehicles can position its forks at any height so that conveyors or load stands with different height in the material handling system can all be served. It is one of the most expensive AGVS types, so they are applied only in systems where full automation is required. A system with these vehicles requires a more intricate path layout and a method for accurately positioning the loads on the floor or on stands. It also requires greater discipline than other systems.

5. AGVS light-load transporters: They are used to handle small, light parts over a moderate distance and to distribute the parts between storage and number of workstations. They are designed to operate in areas with limited space.

6. AGVS assembly-line vehicles: are adaptation of the light-load transporter for applications involving serial assembly processes. The guided vehicle carries major subassemblies such motors, transmissions, or even automobiles. As the vehicle moves from one station to the next, succeeding assembly operations are performed. The major advantage of the AGVS assembly line is lower expense and ease of installation compared with hard assembly lines. The line can easily be changed by adjusting the guide path if necessary and by reprogramming

AGVS guidance systems

· The primary objective of a guidance system is to keep the vehicle in the pre-designated path. The main advantage of AGVS guidance is that the guide path can be changed easily at low cost compared with the high cost of modifying fixed-path equipment such as conveyors, chains, and low lines. The selection will depend on need, application, and environmental constraints.

1. Wire-Guided guidance system: an energized wire is embedded in the floor along the AGV guide path.

2. Optical guidance: colorless fluorescent particles are painted or taped on to the carpeted, tiled, or concrete floor. Photo-sensors on the vehicle read and track these colorless particles.

3. Inertial guidance system: the system has an onboard microprocessor that is used to steer the vehicle on a preprogrammed path. A sonar system is used for obstacle detection and a gyroscope for directional change.

4. Infrared guidance system: this system consists of infrared light transmitters, reflectors mounted in the roof of the facility to reflect the light, and radar-like detectors to relay reflected light signals to the computer. The computer then determines the position and direction of travel of the vehicle.

5. Laser guidance system: a laser beam is used to scan wall-mounted bar-coded reflectors. Accurate location and maneuvering of an AGV are achieved through known distances.

6. Teaching-Type guidance system: neural network concepts are used. A programmed vehicle learnstheguidepathby“walkingthrough”thedesired route. It then informs the host computer what is has learned about the new path. The host computer, in turn, passes information about the new path to other automated guided vehicles.

AGVS Steering Control

The steering control of an AGVS can control the vehicle to negotiate a turn and to maneuver physically in different ways. Two basic type of AGVS steering control systems are used for this purpose:

1. Differential-speed steer control: uses an amplitude-detection type of guidance sensor. The control is based on balancing of signals from the left and right sensors in front of the vehicle. Whenever a difference exists between the amplitudes of the right and left signals, the steering system compensates by correcting the steering.

2. Steered-wheel steer control: uses a phase-detection type of guidance sensor to determine whether the vehicle is to the left or right of the path by detecting the positive or negative phase of the sensor signal received from the guided path wore. Vehicles with steered-wheel steer control have excellent tolerance along the guide path.

AGVS Routing

· AGVS routing means determining how the vehicle negotiates the path to take the shortest route from one point to another. The commonly used methods are:

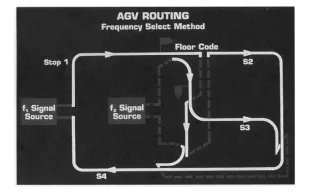

1. Frequency select method: Demonstrated in Figure, the location where a path splits into two or more than two separate directions is called a decision point. At the decision point the vehicle reads a marker (a passive code device in form of magnet, or code device) in the floor, where multiple frequencies are present to allow the vehicle to go into multiple directions. The vehicle selects a frequency for the direction it wants to follow.

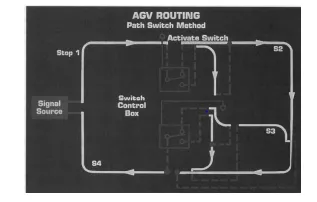

2. Path-switch select: the guide path is divided into segments that are switch on and off by separate floor controls. Only one frequency is used. At the decision points the controls are switched on and off depending on the path to be followed. The vehicle chooses the proper path in the frequency select method. For this reason the path-switch select method is less preferred than the frequency select method.

AGVS control systems

Three types of AGVS control systems are available:

1. Computer-controlled system: is most efficient, but it is also the most expensive and complex type of control system.

2. Remote dispatch control system: most remote dispatch control systems have automatic loading and unloading capability.

3. Manual control system: is simple and the least expensive of all control systems. The efficiency of the system depends on the skill and performance of the operator.

Interface with other subsystems

The computer-controlled system may interface the AGVS materials-handling system with other subsystems in the organization. The subsystem include:

1. Automated storage and retrieval systems

2. Flexible manufacturing systems

3. Computer numerical control (CNC) machines

4. Process control equipment 5. Shop floor control system

This interface may be through either a distributed data processing network or the host computer.

AGVS load transfer

Loading and unloading the AGVS vehicle is also known as AGVS load transfer.

The load transfer operations can be separated into two categories:

1. Manual load transfer:

· Manually coupling and uncoupling towed trailers

· Loading and unloading for forklift truck

· Loading and unloading by roller

· Manually loading and unloading the AGVS vehicle

2. Automatic loading and unloading can be accomplished in many different ways:

· Automatic couple and uncouple

· Powered roller, belt, and chain

· Powered lift and lower device

· Powered push or pull device

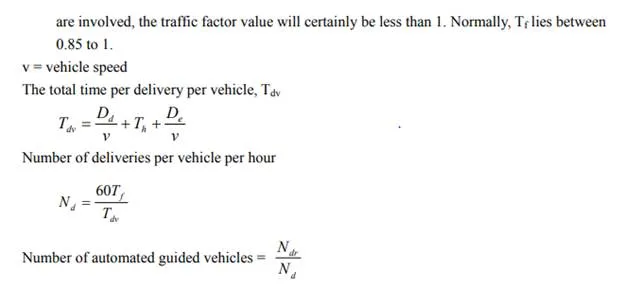

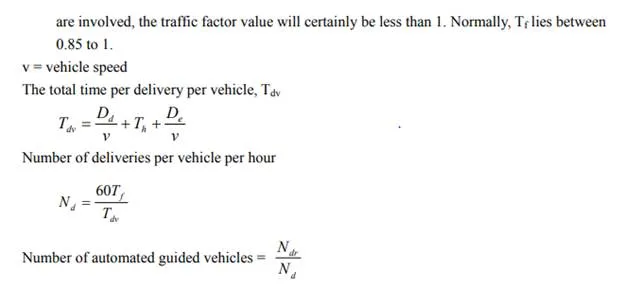

Number of AGV Required

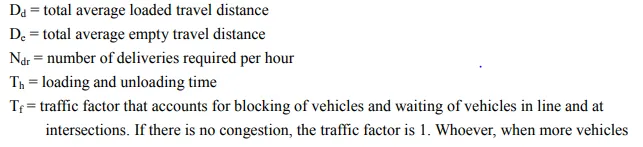

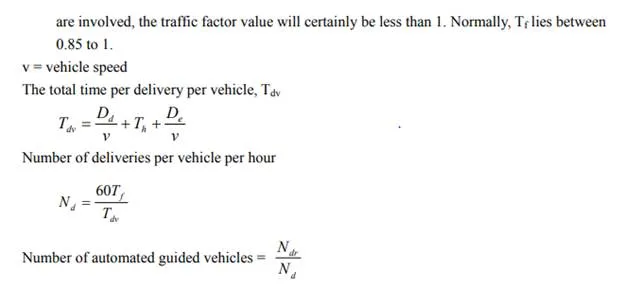

A simple analysis to determine the number of vehicles:

Automated Storage and Retrieval Systems (AS/RS) l To get right parts, pallets, fixtures, and tools to the right place at the right time, an efficient system for their storage and retrieval together with a material transportation system is required. l An integrated FMS, AGVS, and AS/RS system provides an efficient production system for manufacturing low- to medium- volume and middle- to high-variety products. Function of storage systems and definition of AS/RS l Receiving, identification and sorting, dispatching to storage, placing in storage, storage, retrieving from storage, order accumulation, packing, shipping, and record keeping for raw

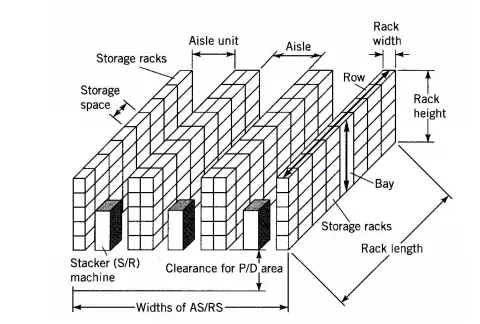

materials, purchased parts, work in process, finished product, pallets, fixtures, tools, spare parts, rework and scrap, office supplies, and so forth have traditionally been considered the functions of storage systems. l An AS/RS attempts to achieve these functions by automating most of these procedures in a cost-effective and efficient manner. l In general, an AS/RS performs a basic set of operations without human intervention, regardless of the specific type of system that is employed. 1. Automatic removal of an item from a storage location 2. Transportation of this item to a specific processing or interface point 3. Automatic storage of an item in a predetermined location, having received an item from a processing or interface point AS/RS components and terminology used An automated storage and retrieval system comprises the following: 1. A series of storage aisles having storage racks 2. Storage and retrieval (S/R) machines, normally one machine per aisle, to store and retrieve materials 3. One or more pickup and delivery stations where materials are delivered for entry to the system and materials are picked up from the system.