Functions and features of actuators (pneumatic cylinders)

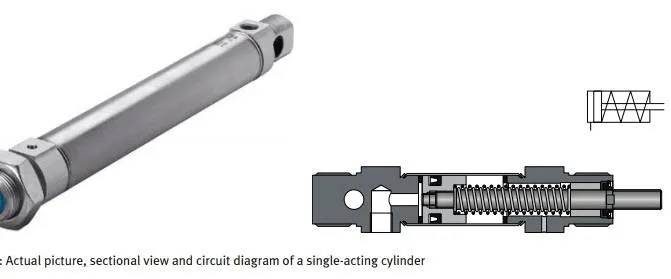

Single-acting cylinders

Single-acting cylinders are supplied with compressed air at one end only, where they have a port for the compressed air supply. This means they can only work in one direction. The cylinder chamber must be exhausted before the return stroke, after which retraction of the piston rod can be initiated by a built-in spring or through the application of external force (see Figure 5.4). Exhausting takes place through a hole in the cylinder end cap.

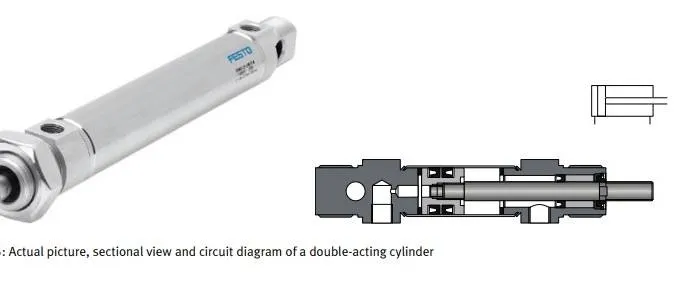

Double-acting cylinders

Double-acting cylinders are supplied with compressed air at both ends. This means these cylinders can also work in both directions. The force transferred to the piston rod is slightly greater for the forward stroke than for the return stroke, since the area supplied with compressed air is greater on the piston side than on the piston rod side (see Figure 5.5). The double-acting cylinder has a port for each pressurised chamber. Before switching to the reverse direction, the appropriate chamber (piston side or piston rod side) must first be exhausted.