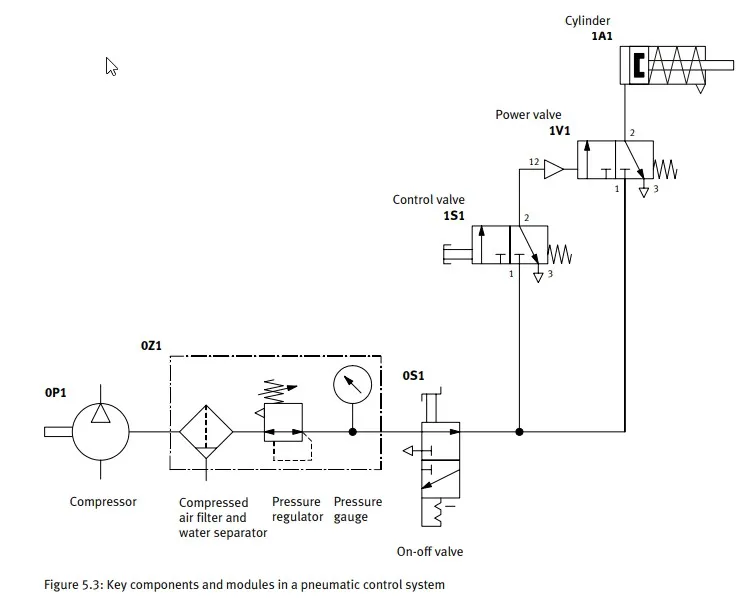

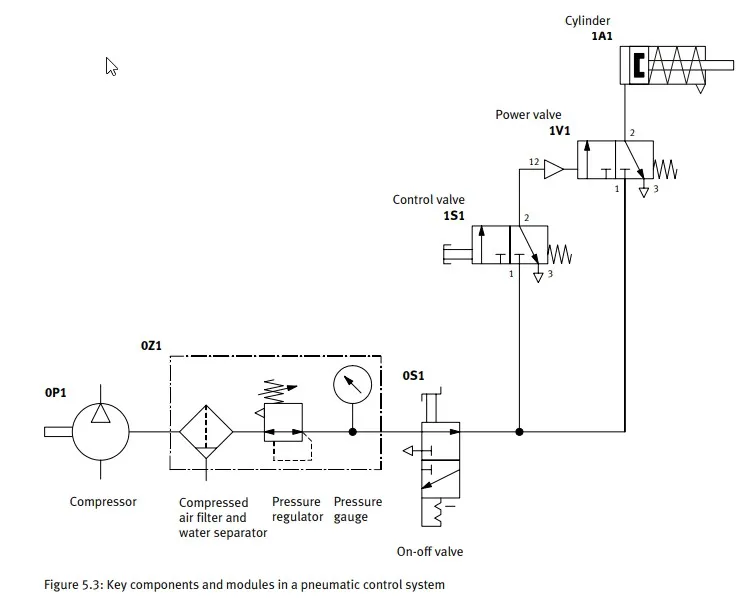

Individual components in a pneumatic control system and their functions

Compressor

The energy for compressed air networks is supplied by screw or piston compressors. They supply an output pressure of 700 – 800 kPa (7 – 8 bar). This ensures that a working pressure of at least 600 kPa (6 bar) is available at the cylinder, notwithstanding leakages (defective points at which air can unintentionally escape) and line losses.

Compressed air filters

Compressed air filters are placed centrally or decentrally upstream of the compressed air system. They remove condensate and any particles of dirt taken in. Properly filtered compressed air plays a major role in prolonging the service life of downstream components.

Pressure regulator

The pressure regulator is where the necessary pressure level for individual sub-systems is set. It compensates fluctuations in the compressed air network. The set pressure remains constant as long as the pressure at the regulator input is at least 50 kPa (0.5 bar) above the required setpoint pressure.

On-off valves

Separate individual compressed air networks.

Control valves

Shut off the compressed air and route it to the operating elements at the required time. The safety and reliability of the system depend on the elements being correctly interconnected.

Power valves

Are adapted to the cylinder diameter and supply the cylinders with the necessary quantity of compressed air.

Cylinders

Pneumatic cylinders are sturdy operating elements with a low susceptibility to failure and a long service life. The right cylinder dimensions can produce high speeds. For fault-free operation, the cylinders must be correctly sized and assembled.