GUIDELINES FOR THE DESIGN OF LACING SYSTEM

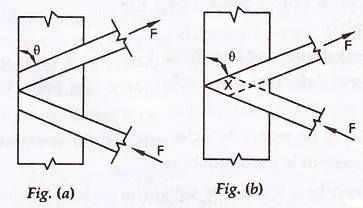

The angle of inclination of the lacing with the longitudinal axis of the column should be between ![]() to

to ![]() .

.

of the lacing bars should not exceed 145.

of the lacing bars should not exceed 145.No.

| Type of lacing

| Effective length,

|

1

| Single lacing, riveted at ends

| Length between inner end rivets on lacing bar.

|

2

| Double lacing, riveted at ends

| 0.7 times the length between end rivets on lacing bars.

|

3

| Welded lacing

| 0.7 times the distance between inner ends or effective lengths of welds at ends.

|

or 0.7 times maximum slenderness ratio of the compression member as a whole, whichever is less.

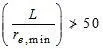

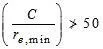

or 0.7 times maximum slenderness ratio of the compression member as a whole, whichever is less.Here, L = distance between the centers of connections of the lattice bars, and

![]() = the minimum radius of gyration of the components of the compression member.

= the minimum radius of gyration of the components of the compression member.

Nominal rivet diameter (mm) | 22 | 20 | 18 | 16 |

Width of lacing bars (mm) | 65 | 60 | 55 | 50 |

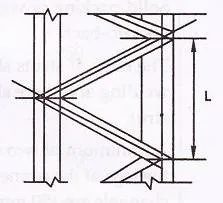

, for single lacing;

, for single lacing;

![]() , for double lacing

, for double lacing

Where ![]() = length between inner end rivets.

= length between inner end rivets.

WELDED CONNECTION

Lap Joint – Overlap should not be less than ¼ times thickness of bar or member, whichever is less.

Butt Joint – Full penetration butt weld or fillet weld on each side, lacing bar should be placed opposite to flange or stiffening component of main member.

BATTENS

Compression members composed of two main components battened should preferably have these components of the same cross-section and symmetrically disposed about their X – X axis.

The battens should be placed opposite to each-other at each end of the member and at points where the member is stayed in its length, and should as far as practicable, be spaced and proportioned uniformly throughout.

The effective length of columns should be increased by 10 percent.

Design Details of Battens

or 0.7 times the slenderness ratio of the compression member as a whole about X – X axis (parallel to battens) whichever is less.

or 0.7 times the slenderness ratio of the compression member as a whole about X – X axis (parallel to battens) whichever is less. for intermediate batten

for intermediate batten

d > a, for end batten

d > 2b , for any batten

where d = effective depth of batten

a = centroidal distance of members

b = width of members in the plane of battens.

Where, ![]() = distance between the innermost connecting line of rivets or welds.

= distance between the innermost connecting line of rivets or welds.

DESIGN OF BATTENS

Battens should be designed to carry bending moment and shear arising from a transverse shear,

Where P = total axial load in the compression member.

Transverse shear V is divided equally between the parallel planes of battens. Battens and their connections to main components resist simultaneously a longitudinal shear.

and , moment

due to transverse shear V.

where, C = spacing of battens

N= number of parallel planes of battens

S= minimum transverse distance between centroid of rivet group or welding.

The end connections should also be designed to resist the longitudinal shear force ![]() and the moment M.

and the moment M.

For welded connection

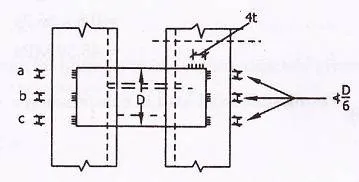

a + b+ c < D/2

let t = thickness of batten

Length of continuous weld at each edge of batten < 1/3 of total length required.

Return weld along transverse axis of the column < 4t

Where, t and D are the thickness and overall depth of battens, respectively.