What is Floor Screed? Its Types, Materials, Construction and Applications

Floor screed is composed of cementitious materials and sand blended based on a suitable mix design and applied to provide a leveled surface for the floor finish which is introduced to the surface of the floor screed.

So, floor screed is the base for the floor finish and greatly influences the performance of floor finish. In this article, different aspects of floor screed will be explored.

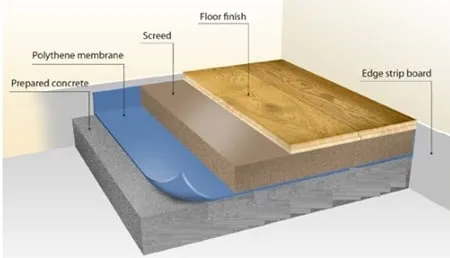

Fig.1: Details of Floor Screed

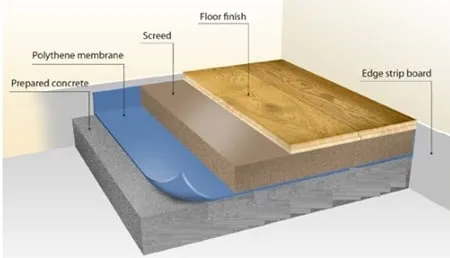

Fig.2: Floor Screed Construction

Following points regarding flooring screeds are discussed:

Types of Floor Screed

There are different types of floor screed that is specified based on the requirements and applications and the functionality of the floor:

Fig.3: Different Types of Floor Screeds; (A) Bonded Screed, (B) Floated Screed, (C) Unbonded Screed and (D) Heated Screed

Fig.4: Bonded Screed Floor

Fig.5: Floated Screed Floors

Fig.6: Unbonded Screed Floors

Fig.7: Heated Screed Floor

Materials for Floor Screed

Following are the materials used for construction of floor screeds:

The above components are adequately blended based on the prepared material proportions. If the thickness of the floor screed does not exceed 40mm, then the recommended mix is 1 Portland cement: 3 sands or 1 Portland cement: 4.5 sand.

However, 1 cement: 1.5fine sand: 3 coarse aggregate (10 mm maximum aggregate size) should be considered if the floor screed thickness is greater than 40mm.

It should be known that drying shrinkage gets reduced as the proportion of cement to sand is decreased.

Suitable amount of water should be specified to provide required workability since excessive water would reduce floor screed strength and inadequate water quantity lead to poor compaction.

What are the Requirements that a Floor Screed Should Meet?

Floor screeds should have adequate thickness which is based on the screed type and application frequencies. Recommended floor screed thickness based on the type of the screed floor and the construction conditions are provided in Table-1.

Table-1: Recommended Floor Screed Based on the Type of Screed and Construction Condition

Recommended floor screed thickness, mm | Floor screed type and construction condition |

12 | For monolithic construction. In this case floor screed will be placed no longer than 3 hours after the placement of concrete. This will guarantee a satisfactory bond between floor screed and placed concrete beneath it. |

40 | For screed floor placed on hardened concrete. The concrete should be cut by appropriate means then cleaned, wetted and finally screed is placed. Not only will this ensure good bond but also make the screed to dry slowly and prevent cracks. |

50 | For floor screed placed on impermeable damp proof membrane. In this case a bond between the screed and the layer below it would not exist and hence shrinkage is unrestrained. |

65 | For screed installed on compressible course of sound or heat insulation material. This is recommended for domestic application only, otherwise the thickness of the screed should be increased. Lesser thickness will suffer from crack development. |

75 | For screed installed on compressible course of sound or heat insulation material. This is advised for applications other than domestic utilization. Lesser thickness will suffer from crack development. |

Procedure of Floor Screeding

How a Successful Screed Floor can be Constructed?