Contact mechanics

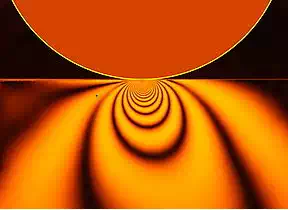

Stresses in a contact area loaded simultaneously with a normal and a tangential force. Stresses were made visible using photoelasticity.

Contact mechanics is the study of the deformation of solids that touch each other at one or more points. A central distinction in contact mechanics is between stresses acting perpendicular to the contacting bodies' surfaces (known as the normal direction) and frictional stresses acting tangentially between the surfaces. This page focuses mainly on the normal direction, i.e. on frictionless contact mechanics. Frictional contact mechanics is discussed separately. Normal stresses are caused by applied forces and by the adhesionpresent on surfaces in close contact even if they are clean and dry. Contact mechanics is part of mechanical engineering. The physical and mathematical formulation of the subject is built upon the mechanics of materials and continuum mechanics and focuses on computations involving elastic, viscoelastic, and plastic bodies in static or dynamic contact. Contact mechanics provides necessary information for the safe and energy efficient design of technical systems and for the study of tribology, contact stiffness, electrical contact resistance and indentation hardness. Principles of contacts mechanics are implemented towards applications such as locomotive wheel-rail contact, coupling devices, brakingsystems, tires, bearings, combustion engines, mechanical linkages, gasket seals, metalworking, metal forming, ultrasonic welding, electrical contacts, and many others. Current challenges faced in the field may include stress analysis of contact and coupling members and the influence of lubrication and material design on friction and wear. Applications of contact mechanics further extend into the micro- and nanotechnological realm.

The original work in contact mechanics dates back to 1882 with the publication of the paper "On the contact of elastic solids"[3]("Ueber die Berührung fester elastischer Körper") by Heinrich Hertz. Hertz was attempting to understand how the optical properties of multiple, stacked lenses might change with the force holding them together. Hertzian contact stress refers to the localized stresses that develop as two curved surfaces come in contact and deform slightly under the imposed loads. This amount of deformation is dependent on the modulus of elasticity of the material in contact. It gives the contact stress as a function of the normal contact force, the radii of curvature of both bodies and the modulus of elasticity of both bodies. Hertzian contact stress forms the foundation for the equations for load bearing capabilities and fatigue life in bearings, gears, and any other bodies where two surfaces are in contact.

History

When a sphere is pressed against an elastic material, the contact area increases.

Classical contact mechanics is most notably associated with Heinrich Hertz. In 1882, Hertz solved the contact problem of two elastic bodies with curved surfaces. This still-relevant classical solution provides a foundation for modern problems in contact mechanics. For example, in mechanical engineering and tribology, Hertzian contact stress is a description of the stress within mating parts. The Hertzian contact stress usually refers to the stress close to the area of contact between two spheres of different radii.

It was not until nearly one hundred years later that Johnson, Kendall, and Roberts found a similar solution for the case of adhesive contact. This theory was rejected by Boris Derjaguin and co-workers who proposed a different theory of adhesion in the 1970s. The Derjaguin model came to be known as the DMT (after Derjaguin, Muller and Toporov) model, and the Johnson et al. model came to be known as the JKR (after Johnson, Kendall and Roberts) model for adhesive elastic contact. This rejection proved to be instrumental in the development of the Tabor and later Maugis parameters that quantify which contact model (of the JKR and DMT models) represent adhesive contact better for specific materials.

Further advancement in the field of contact mechanics in the mid-twentieth century may be attributed to names such as Bowdenand Tabor. Bowden and Tabor were the first to emphasize the importance of surface roughness for bodies in contact. Through investigation of the surface roughness, the true contact area between friction partners is found to be less than the apparent contact area. Such understanding also drastically changed the direction of undertakings in tribology. The works of Bowden and Tabor yielded several theories in contact mechanics of rough surfaces.

The contributions of Archard (1957) must also be mentioned in discussion of pioneering works in this field. Archard concluded that, even for rough elastic surfaces, the contact area is approximately proportional to the normal force. Further important insights along these lines were provided by Greenwood and Williamson (1966), Bush (1975), and Persson (2002).The main findings of these works were that the true contact surface in rough materials is generally proportional to the normal force, while the parameters of individual micro-contacts (i.e., pressure, size of the micro-contact) are only weakly dependent upon the load.