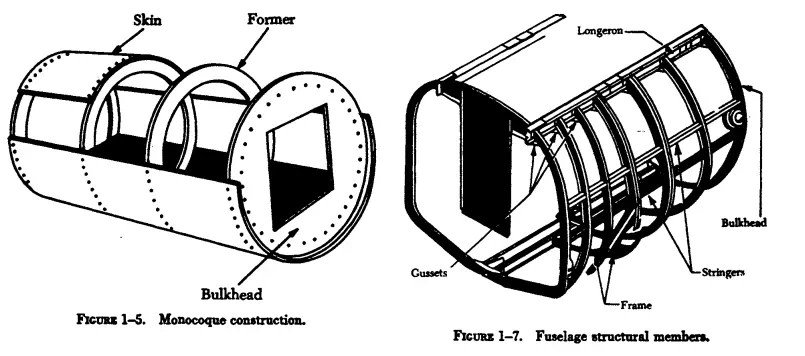

Semimonocoque Type

The semimonocoque fuselage is constructed pri· marily of the alloys of aluminum and magnesium, although steel and titanium are found in areas of high temperatures. Primary bending loads are taken by the longerons, which usually extend across sev· eral points of support. The longerons are supplemented by other longitudinal members, called stringers. Stringers are more numerous and lighter in weight than longerons. The vertical structural members are referred to as bulkheads, frt1111a, tJ7Ul formers. The heaviest of these vertical members are located at intervals to carry concentrated loads and at points where fittings are used to attach other units, such as the wings, powerplants, and stabilizers. Figure 1-7 shows one form of the semimonocoque design now in use.

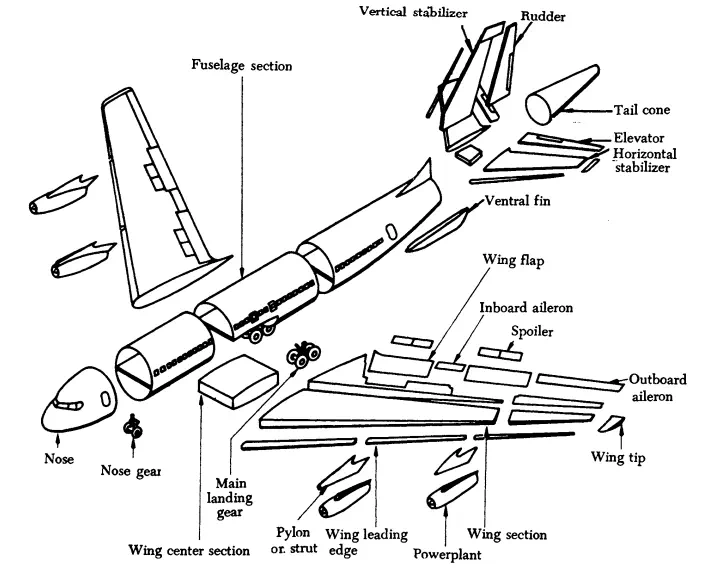

Typical structural components of a turbine powered aircraft.

The stringers are smaller and lighter than Ionge4 rons and serve as fill-ins. They have some rigidity, but are chiefly used for giving shape and for attachment of the skin. The strong, heavy longerons hold the bulkheads and formers, and these, in tum, hold the stringers. All of these joined together form a rigid fuselage framework.

There is often little di1Jerence between some rings, frames, and formers. One manufacturer may call a brace a former, whereas another may call the same type of brace a ring or frame. Manufacturers' instructions and specifications for a specific aircraft are the best guides.

Stringers and longerons prevent tension and compression from bending the fuselage. Stringers are usually of a one-piece aluminium alloy construction, and are manufactured in a variety of shapes by casting, extrusion, or forming. Longerons, like stringers, are usually made of aluminium alloy; however, they may be of either a one-piece or a built-up construction.

By themselves, the structural members discussed do not give strength to a fuselage. They must first be joined together by such connective devices as gussets, rivets, nuts and bolts, or metal screws. A gusset (figure 1-7) is a type of connecting bracket. The bracing between longerons is often referred to as web members. They may be installed vertically or diagonally.

The metal skin or covering is riveted to the longerons, bulkheads, and other structural members and carries part of the load. The fuselage skin thickness will vary with the load carried and the stresses sustained at a particular location.

There are a number of advantages in the use of the semimonocoque · fuselage. The bulkheads, frames, stringers, and longerons facilitate the design and construction of a streamlined fuselage, and add to the strength and rigidity of the structure. The main advantage, however, lies in the fact that it does not depend on a few members for strength and rigidity. This means that a semimonocoque fuselage,because of its stressed-skin construction, may with· stand considerable damage and still be strong enough to hold together.

Fuselages are generally constructed in two or more sections. On small aircraft, they are generally made in two or three sections, while larger aircraft may be made up of as many as six sections.

Quick access to the accessories and other equipment carried in the fuselage is provided for by numerous access doors, inspection plates, landing wheel wells, and other openings. Servicing diagram showing the arrangement of equipment and location of access doors are supplied by the manufacturer in the aircraft maintenance manual.