Antitorque System

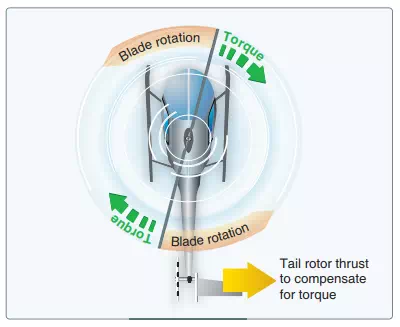

Helicopters with a single, main rotor system require a separate antitorque system. This is most often accomplished through a variable pitch, antitorque rotor or tail rotor. [Figure 4-12] Pilots vary the thrust of the antitorque system to maintain directional control whenever the main rotor torque changes, or to make heading changes while hovering. Most helicopters drive the tail rotor shaft from the transmission to ensure tail rotor rotation (and hence control) in the event that the engine quits. Usually, negative antitorque thrust is needed in autorotations to overcome transmission friction.

Antitorque rotor produces thrust to oppose torque.

Fenestron

Another form of antitorque system is the fenestron or “fanin-tail” design. This system uses a series of rotating blades shrouded within a vertical tail. Because the blades are located within a circular duct, they are less likely to come into contact with people or objects.

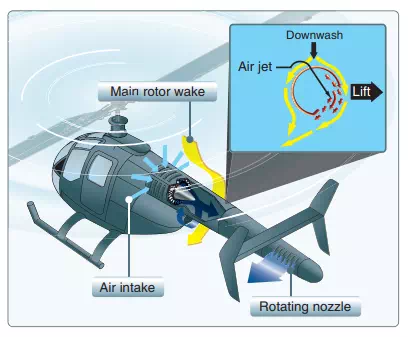

NOTAR®

Using the natural characteristics of helicopter aerodynamics, the NOTAR antitorque system provides safe, quiet, responsive, foreign object damage (FOD) resistant directional control. The enclosed variable-pitch composite blade fan produces a low pressure, high volume of ambient air to pressurize the composite tailboom. The air is expelled through two slots which run the length of the tailboom on the right side, causing a boundary-layer control called the Coanda effect. The result is that the tailboom becomes a “wing,” flying in the downwash of the rotor system, producing up to 60 percent of the antitorque required in a hover. The balance of the directional control is accomplished by a rotating direct jet thruster. In forward flight, the vertical stabilizers provide the majority of the antitorque; however, directional control remains a function of the direct jet thruster. The NOTAR antitorque system eliminates some of the mechanical disadvantages of a tail rotor, including long drive shafts, hanger bearings, intermediate gearboxes and 90° gearboxes.

Fenestron or “fan-in-tail” antitorque system. This design provides an improved margin of safety during ground operations.

While in a hover, Coanda effect supplies approximately two-thirds of the lift necessary to maintain directional control. The rest is created by directing the thrust from the controllable rotating nozzle.