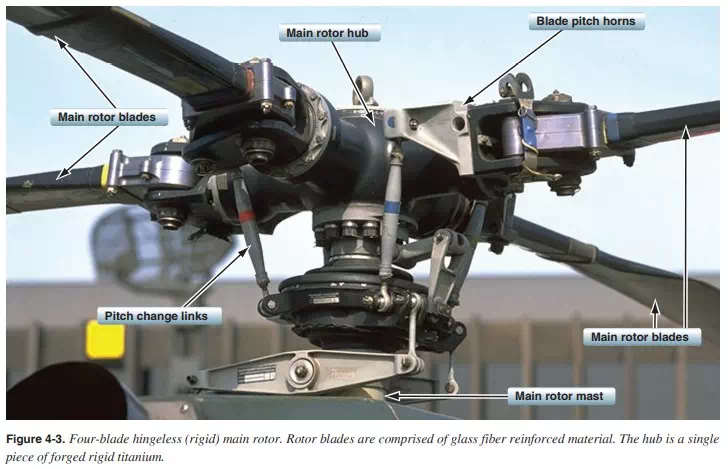

Rigid Rotor System

The rigid rotor system shown in Figure 4-3 is mechanically simple, but structurally complex because operating loads must be absorbed in bending rather than through hinges. In this system, the blade roots are rigidly attached to the rotor hub. Rigid rotor systems tend to behave like fully articulated systems through aerodynamics, but lack flapping or lead/ lag hinges. Instead, the blades accommodate these motions by bending. They cannot flap or lead/lag, but they can be feathered. As advancements in helicopter aerodynamics and materials continue to improve, rigid rotor systems may become more common because the system is fundamentally easier to design and offers the best properties of both semirigid and fully articulated systems.

The rigid rotor system is very responsive and is usually not susceptible to mast bumping like the semirigid or articulated systems because the rotor hubs are mounted solid to the main rotor mast. This allows the rotor and fuselage to move together as one entity and eliminates much of the oscillation usually present in the other rotor systems. Other advantages of the rigid rotor include a reduction in the weight and drag of the rotor hub and a larger flapping arm, which significantly reduces control inputs. Without the complex hinges, the rotor system becomes much more reliable and easier to maintain than the other rotor configurations. A disadvantage of this system is the quality of ride in turbulent or gusty air. Because there are no hinges to help absorb the larger loads, vibrations are felt in the cabin much more than with other rotor head designs.

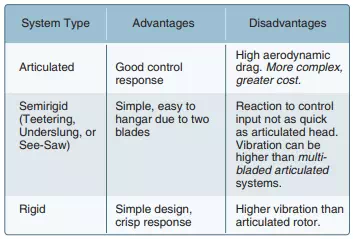

There are several variations of the basic three rotor head designs. The bearingless rotor system is closely related to the articulated rotor system, but has no bearings or hinges. This design relies on the structure of blades and hub to absorb stresses. The main difference between the rigid rotor system and the bearingless system is that the bearingless system has no feathering bearing—the material inside the cuff is twisted by the action of the pitch change arm. Nearly all bearingless rotor hubs are made of fiber-composite materials. The differences in handling between the types of rotor system are summarized below