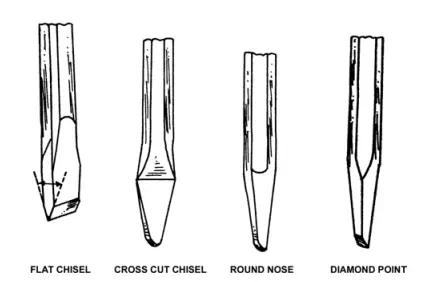

Chisels

There is a fairly good variety of chisels used for chipping work by a fitter. Some very commonly used forms are Flat, Cross-cut or cape, Round nose and Diamond point chisels (Fig. 2.17). All the chisels are forged from bar stock of carbon steel, usually of octagonal or hexagonal cross-section to the desired shape and the cutting edge ground to the correct angle. The forgoing operation is followed by annealing, hardening and tempering to make chisel body tough and obtain a sharp cutting edge. Full length of the chisel is never hardened, only a small length above the cutting edge (say about 20 to 30 cm) is subjected to this treatment so that the remaining length if left tough and comparatively softer. The included angle at the cutting edge varies between 40 degree and 70 degree depending upon the material on which it is to be used. Approximate cutting angles for common materials are as follows:

Brass and copper : 40o

Wrought iron : 50o

Cast iron and general cutting work : 60o

Steel (cast) : 70o

a. Flat Chisel

It is a general purpose chisel which is most widely used in cutting work, chipping large surfaces, cutting metal sheets, rods, bar stocks and similar other purposes. Since it cuts the metal in cold state it is also frequently known as cold chisel. In grinding, its cutting edge is given a slight rounding so as to prevent the corners from digging into the metal.

b. Cross Cut Chisel or Cape Chisel

It is a comparatively narrow chisel having its cutting edge slightly broader than the blade. It is done to keep the blade free when the chisel is used to cut deep into the metal. Normal widths of the cutting edge vary from 3 mm to 122 mm. This chisel is used to cut parallel grooves on large surfaces before chipping by means of a flat chisel cutting key ways etc.

c. Round Nose Chisel

It is used for drawing the eccentric hole back to correct centre which has run-off centre during drilling operation. Another specific use of this type of chisel is in cutting oil grooves and channels in bearing and pulley bushes and cleaning small round corners.

d. Diamond Point Chisel

It is a special purpose chisel used for chipping rough plates and cutting cast iron pipes, cutting ‘V’ grooves, chipping sharp corners, to square up corners of previously cut slots and cleaning angles.

Other chisels can be made in desired shapes to suit the work. A particular form known as side chisel, is very useful in cleaning and finishing up slots which have been previously drilled such as cotter ways etc. Chisels which are used in electric or pneumatic hammers have similar cutting edges but their heads are made to have a parallel shank so as to suit the socket of the hammer.