Gas Turbine Engines

The gas turbine is an internal combustion engine that uses air as the working fluid. The engine extracts chemical energy from fuel and converts it to mechanical energy using the gaseous energy of the working fluid (air) to drive the engine and propeller, which, in turn, propel the airplane.

The basic principle of the airplane turbine engine is identical to any and all engines that extract energy from chemical fuel. The basic 4 steps for any internal combustion engine are:

1. Intake of air (and possibly fuel).

2. Compression of the air (and possibly fuel).

3. Combustion, where fuel is injected (if it was not drawn in with the intake air) and burned to convert the stored energy.

4. Expansion and exhaust, where the converted energy is put to use.

In the case of a piston engine, such as the engine in a car or reciprocating airplane engine, the intake, compression, combustion, and exhaust steps occur in the same place (cylinder head) at different times as the piston goes up and down.

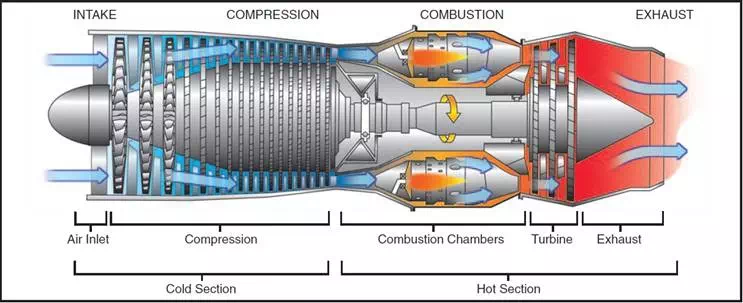

In the turbine engine, however, these same four steps occur at the same time but in different places. As a result of this fundamental difference, the turbine has engine sections called:

1. The inlet section

2. The compressor section

3. The combustion section (the combustor)

4. The turbine (and exhaust) section.

The turbine section of the gas turbine engine has the task of producing usable output shaft power to drive the propeller. In addition, it must also provide power to drive the compressor and all engine accessories. It does this by expanding the high temperature, pressure, and velocity gas and converting the gaseous energy to mechanical energy in the form of shaft power.

A large mass of air must be supplied to the turbine in order to produce the necessary power. This mass of air is supplied by the compressor, which draws the air into the engine and squeezes it to provide high-pressure air to the turbine. The compressor does this by converting mechanical energy from the turbine to gaseous energy in the form of pressure and temperature.

If the compressor and the turbine were 100% efficient, the compressor would supply all the air needed by the turbine. At the same time, the turbine would supply the necessary power to drive the compressor. In this case, a perpetual motion machine would exist. However, frictional losses and mechanical system inefficiencies do not allow a perpetual motion machine to operate. Additional energy must be added to the air to accommodate for these losses. Power output is also desired from the engine (beyond simply driving the compressor); thus, even more energy must be added to the air to produce this excess power. Energy addition to the system is accomplished in the combustor. Chemical energy from fuel as it is burned is converted to gaseous energy in the form of high temperatures and high velocity as the air passes through the combustor. The gaseous energy is converted back to mechanical energy in the turbine, providing power to drive the compressor and the output shaft.